Preparation method and application of organosilicone sol based on pH swing

A technology of organosilicon sol, organosilicon source, applied in chemical instruments and methods, membrane, semipermeable membrane separation, etc., can solve problems such as poor high temperature resistance, achieve narrow particle size distribution, inhibit hydrolysis and rearrangement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

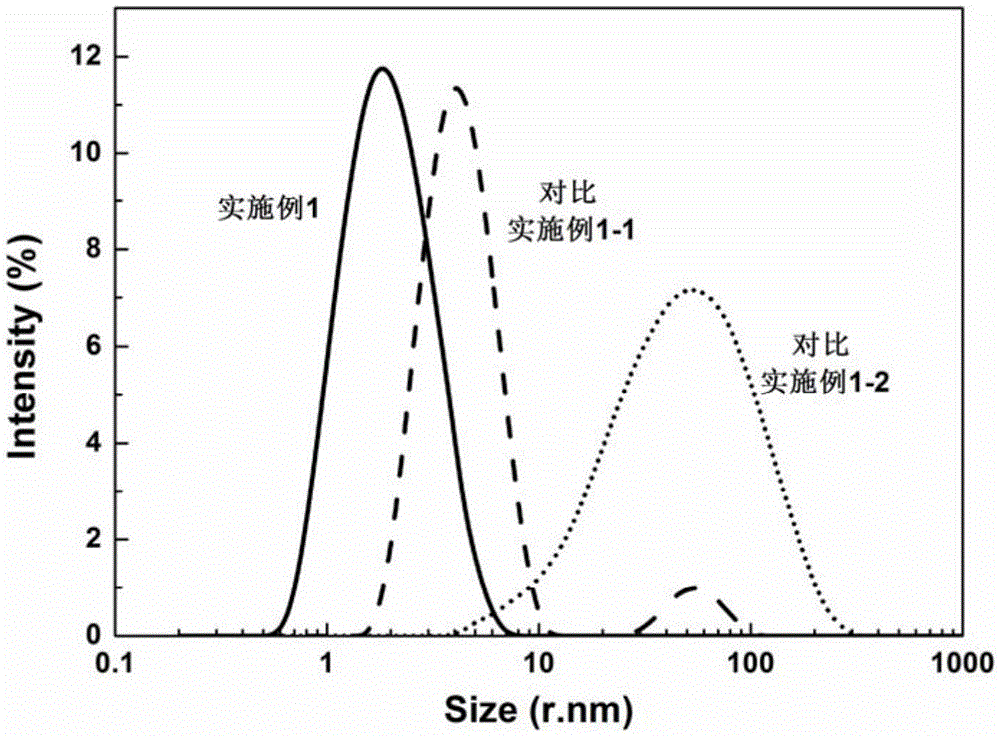

Embodiment 1

[0021] 1. Dissolve 1g of BTESE in 15.59g of absolute ethanol (EtOH) solution, stir in a water bath at 40°C for 5min, and rotate at 500rpm; add 3.05g of deionized water (H 2 O), continue stirring in a water bath at 40°C for 5min, with a rotating speed of 500rpm; BTESE: EtOH: H 2 O=1:120:60 (molar ratio);

[0022] 2. Add concentrated hydrochloric acid with a solute mass fraction of 37% to the above mixed solution, adjust the pH of the mixed solution to 0.8, and continuously stir and react for 1 hour at 40° C. in a water bath at a speed of 500 rpm;

[0023] 3. Slowly add ammonia water to the mixed solution, adjust the pH of the mixed solution to 6.5, react in a water bath at 40°C for 1 hour, and rotate at 500 rpm to prepare a bridged silicone sol;

[0024] 4. Coat the prepared sol with α-Al 2 o 3 The material is calcined at 200° C. to form a film (the thickness of the film is 60 nm) on a supporting film and applied to reverse osmosis desalination.

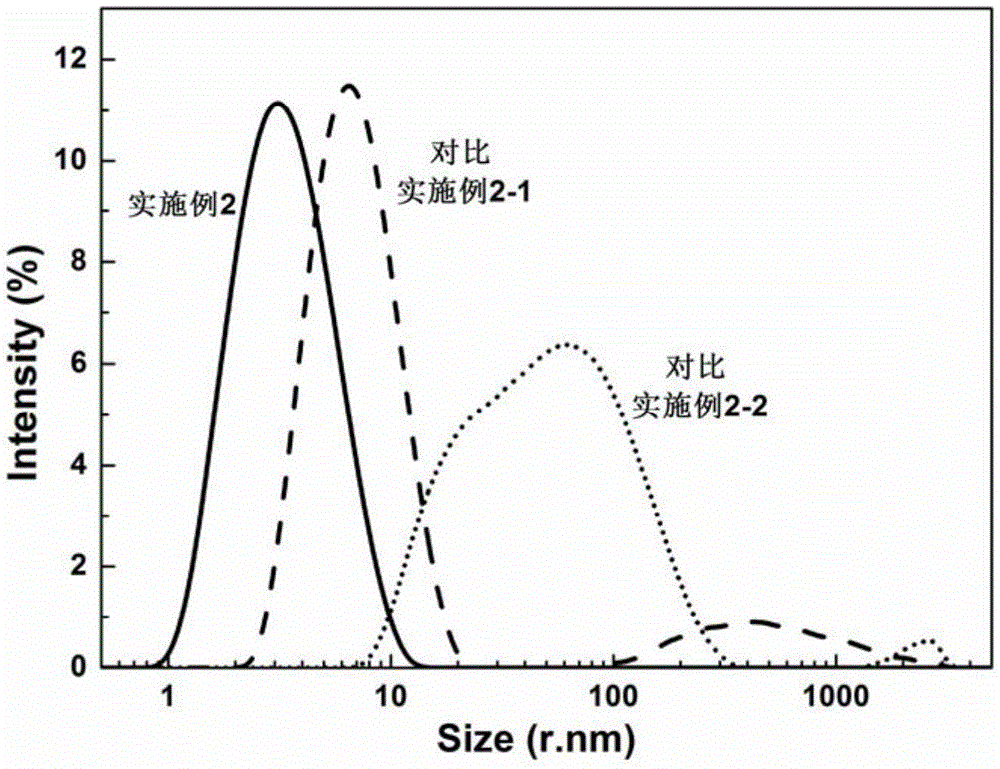

Embodiment 2

[0026] 1. Dissolve 1g of ETMS in 36.79g of EtOH, stir in a water bath at 40°C for 5min, and rotate at 500rpm; add 7.2g of deionized water (H 2 O), continue to stir in a water bath at 40°C for 5min at a speed of 500rpm; ETMS: EtOH: H 2 O=1:120:60 (molar ratio);

[0027] 2. Add concentrated hydrochloric acid with a solute mass fraction of 37% to the above mixed solution, adjust the pH of the mixed solution to 0.8, and continuously stir and react for 1 hour at 40° C. in a water bath at a speed of 500 rpm;

[0028] 3. Slowly add ammonia water to the mixed solution, adjust the pH of the mixed solution to 7, react in a water bath at 40°C for 1 hour, and rotate at a speed of 500 rpm to prepare a side chain organosilicon sol;

[0029] 4. Coat the prepared sol with α-Al 2 o 3 The material is calcined at 200° C. to form a film (the thickness of the film is 60 nm) on a supporting film and applied to reverse osmosis desalination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com