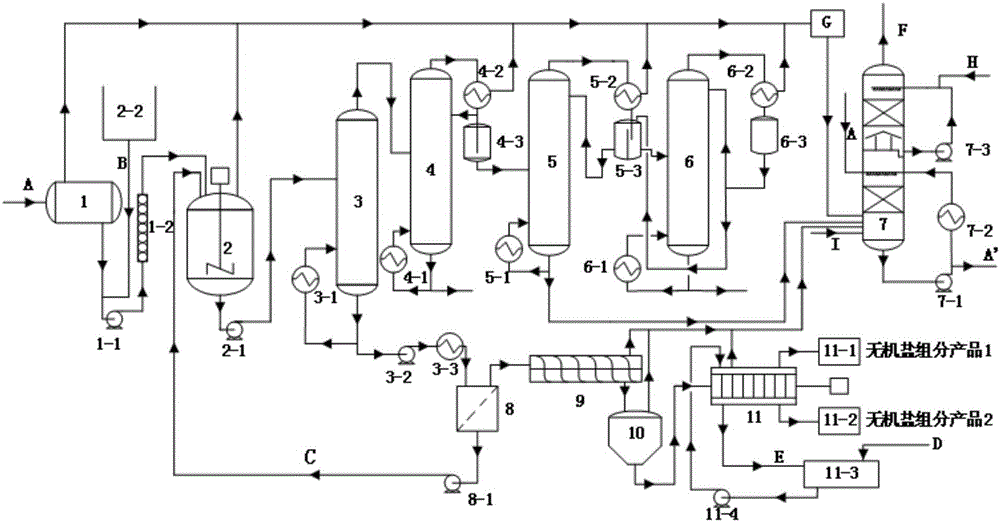

High-purity recycling process system of complex chemical waste liquid

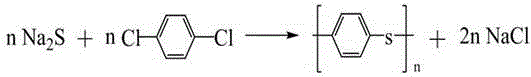

A process system and resource-based technology, applied in the fields of alkali metal halide purification, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve problems such as equipment blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The water content is 30% (wt), NaCl is 10% (wt), NMP is 50% (wt), p-dichlorobenzene is 5%, and other trace impurities with high boiling point are 5%, and the flow rate is 15t / h. Wastewater is transported to the figure 1 Processed in the process system shown. The decomplexing agent used is Na 2 CO 3 The aqueous solution, waste liquid and decomplexing agent are fully mixed by the static mixer 1-2 and then sent to the decomplexing reactor 2 for decomplexing reaction, and the decomplexing reaction is carried out at normal temperature and pressure. The mixed material after decomplexation is sent to the evaporation tower 3 (evaporator with wiped film stirring) for evaporation operation, and its operating pressure is 0.8×10 5 Pa. The evaporated gas-phase material is sent to the rectification tower 4 through the pipeline at the top of the evaporation tower 3, and the concentrated salt solution in the tower kettle is cooled by the heat exchanger 3-3 and then enters the centr...

Embodiment 2

[0027] Will contain 32% (wt) of water, 8% (wt) of KCl, 50% (wt) of NMP, 5% of p-dichlorobenzene, and 5% of other trace impurities with high boiling point, and the flow rate is 20t / h. Wastewater is transported to the figure 1 Processed in the process system shown. The solution used is K 2 CO 3 The aqueous solution, waste liquid and decomplexing liquid are fully mixed by static mixer 1-2 and then sent into decomplexing reactor 2 for decomplexing reaction. The decomplexing reaction is carried out at a pressure of 0.9×10 5 Pa, the temperature is 50 ℃ under the conditions. The mixed material after the decomplexation is transported to the evaporation tower 3 for evaporation operation, and the operating pressure is 0.85×10 5 Pa. The evaporated gas-phase material is sent to the rectification tower 4 through the pipeline at the top of the evaporation tower 3, and the concentrated salt solution in the tower kettle is cooled by the heat exchanger 3-3 and then enters the centrifugal ...

Embodiment 3

[0029] Will contain water as 40% (wt), CaCl 2 10% (wt), 40% (wt) of NMP, 8% of p-dichlorobenzene, and 2% of other trace impurities with high boiling point, the chemical wastewater with a flow rate of 25t / h is sent to such as figure 1 Processed in the process system shown. The decomplexing agent used is an aqueous solution of CaO, and the waste liquid and the decomplexing agent are fully mixed by the static mixer 1-2 and then sent into the decomplexing reactor 2 for the decomplexing reaction, and the decomplexing reaction is carried out at a pressure of 0.85×10 5 Pa, the temperature is carried out under the condition of 45 ℃. The mixed material after the decomplexation is transported to the evaporation tower 3 for evaporation operation, and its operating pressure is 0.8×10 5 Pa. The evaporated gas-phase material is sent to the rectification tower 4 through the pipeline at the top of the evaporation tower 3, and the concentrated salt solution in the tower kettle is cooled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com