Degradable mulching film

A technology for degrading and modifying mulch, which is applied in the field of polymer materials, can solve problems such as poor thermal insulation performance and degradation performance, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

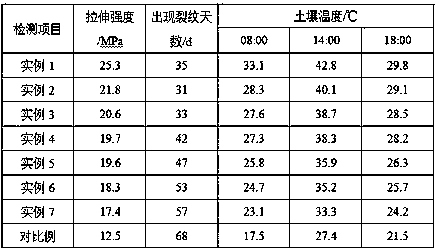

Examples

example 1

[0021]Put (N-amidino) dodecyl acrylamide and polyethylene glycol derivatives in a single-necked flask at a mass ratio of 2:1, and add p-dichlorobenzene and poly Ferrocene, which is 0.10 times the mass of ethylene glycol derivatives, is stirred and mixed for 50 minutes at a rotational speed of 500r / min to obtain a modification additive; add polyvinyl alcohol to water at a mass ratio of 1:100 into the No. 1 beaker , after stirring and mixing with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the No. Ethylene alcohol liquid; add gum arabic powder and water into the No. 2 beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the No. 2 beaker into a digital speed measuring constant temperature magnetic stirrer, The temperature is 100°C, the rotation speed is 500r / min, heat and stir to dissolve for 50min to obtain gum arabic; put carrageenan powder and water in a mass ratio o...

example 2

[0023] Add polyvinyl alcohol and water into No. 1 beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move No. , under the condition of rotating speed of 500r / min, heat and stir to dissolve for 50min to obtain polyvinyl alcohol liquid; add gum arabic powder and water into the No. 4h, then move the No. 2 beaker into a magnetic stirrer with digital display speed measurement and constant temperature, and heat and stir to dissolve for 50min at a temperature of 100°C and a rotation speed of 500r / min to obtain gum arabic solution; mix carrageenan powder and water according to the mass ratio Add 1:100 into the No. 3 beaker, stir and mix with a glass rod for 30 minutes, let it swell for 4 hours, and then move the No. 3 beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of 100 ° C and a speed of 500 r / min. Heat and stir to dissolve for 50 minutes to obtain the carrageen...

example 3

[0025] Put (N-amidino) dodecyl acrylamide and polyethylene glycol derivatives in a single-necked flask at a mass ratio of 2:1, and add p-dichlorobenzene and poly Ferrocene, which is 0.10 times the mass of ethylene glycol derivatives, is stirred and mixed for 50 minutes at a rotational speed of 500r / min to obtain a modification additive; add polyvinyl alcohol to water at a mass ratio of 1:100 into the No. 1 beaker , after stirring and mixing with a glass rod for 30 minutes, let it stand for swelling for 4 hours, then move the No. Ethylene alcohol liquid; add carrageenan powder and water into No. 3 beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move No. 3 beaker into a digital speed measuring constant temperature magnetic stirrer, The temperature is 100°C, the rotation speed is 500r / min, heating and stirring for 50 minutes to dissolve the carrageenan solution; put the corn cobs in a grinder and pulve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com