Ultra-high purity separating and refining technology of wastewater containing NMP (N-Methyl Pyrrolidone) and paradichlorobenzene

A technology for methylpyrrolidone and p-dichlorobenzene is applied in the field of ultra-high-purity separation and purification of wastewater containing N-methylpyrrolidone and p-dichlorobenzene, and can solve problems such as waste of resources, environmental pollution, increased production costs, and the like, achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Recycling of 20t / h wastewater containing NMP and p-dichlorobenzene

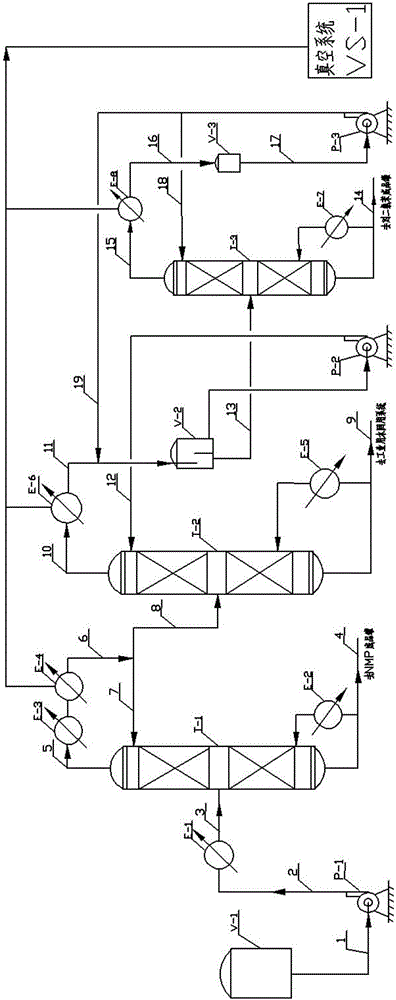

[0018] The operation steps of the ultra-high-purity separation and purification process for wastewater containing NMP and p-dichlorobenzene are as attached Figure 1 shown. The system is mainly composed of rectification tower, reflux tank, heat exchanger, phase separation tank, vacuum system and other equipment. There are metering, control instruments and pipelines between each equipment.

[0019] Wastewater containing 51% water, 45% NMP, and 4% p-dichlorobenzene passes through pump P-1, is preheated to 50°C by heat exchanger E-1, and then enters the first rectification tower T-1. The number of theoretical plates is 40, the diameter of the column is 1.6 meters, and the regular metal plate corrugated packing is used, the material is 316L, the operating pressure is 0.65atm, the reflux ratio is 0.5, and the liquid temperature at the bottom of the first distillation column T-1 is 190°C. 1.5MP...

Embodiment 2

[0023] Example 2: Recycling of 15t / h wastewater containing NMP and p-dichlorobenzene

[0024] The mode of operation is as in Example 1.

[0025] The waste water containing 55% water, 43% NMP and 2% p-dichlorobenzene is transported to the heat exchanger E-1 through the pump P-1 and preheated to 80°C, and then enters the first rectification tower T-1 for separation. -1 column has a theoretical plate number of 60, uses structured wire mesh packing, material is 316L, column diameter is 2.6 meters, structured packing is used inside the column, operating pressure is 0.4atm, reflux ratio is 2.5, the first rectification column The temperature of the liquid at the bottom of T-1 is 165°C, and T-1 uses 1MPa water vapor as a heat source. After being separated by the first rectification tower T-1, the NMP purity of the T-1 tower kettle reaches 99.996wt%, and it can be extracted to the NMP finished product tank through the pipeline 4 for storage. , the temperature of the mixed steam of p-...

Embodiment 3

[0029] Example 3: Recycling of 35t / h waste water containing NMP and p-dichlorobenzene

[0030] The mode of operation is as in Example 1. The waste water containing 48% water, 49% NMP and 3% p-dichlorobenzene is transported to the heat exchanger E-1 by the pump P-1, preheated to 65°C, and then enters the first rectification tower T-1 for separation, T- 1 column has a theoretical plate number of 40, a column diameter of 1.4 meters, ceramic random packing, an operating pressure of 0.45 atm, a reflux ratio of 0.8, and a temperature of liquid at the bottom of the first distillation column T-1 of 175°C. MPa water vapor provides heat source. After being separated by the first rectification tower T-1, the NMP content of the T-1 tower kettle reaches 99.994wt%, and it can be extracted to the NMP finished product tank through the pipeline 4 for storage, at the top of the first rectification tower T-1 , the temperature of the mixed steam of p-dichlorobenzene and water is, then enter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com