Process for synthesizing low-chlorine polyphenylene sulfide resin

A polyphenylene sulfide resin and a synthesis process technology are applied in the field of polymer material resin synthesis to achieve the effects of improving reaction speed, saving costs and shortening synthesis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

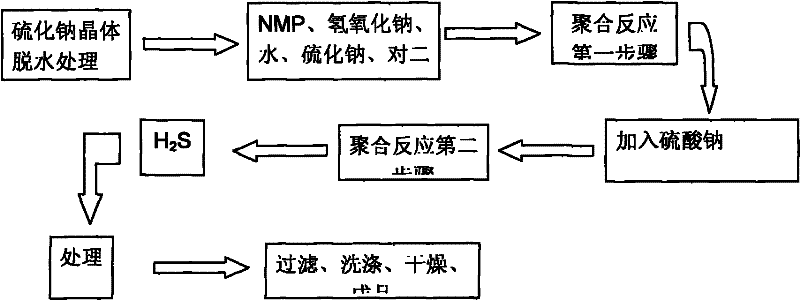

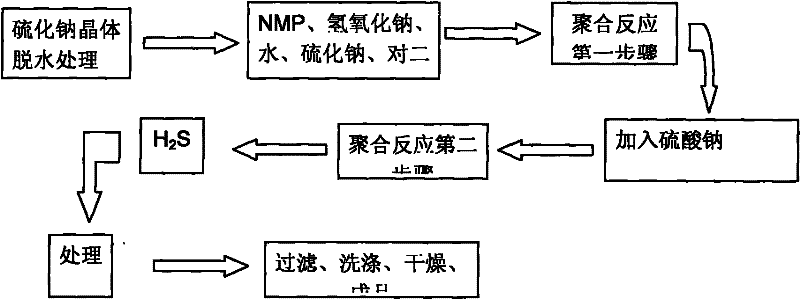

Image

Examples

Embodiment 1

[0024] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 120℃, and the input holding temperature is 120℃. Equipped with three layers of 18cm / layer 5 angstrom molecular sieve water absorption column. After the molecular sieve absorbs water, the molar ratio of sodium sulfide to water in the sodium sulfide solution becomes 1:1.2, then use 4.5mol / molNa 2 The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, and directly flows into the 2L autoclave, and then the molar mass of NaOH is 0.1mol / molNa in the reactor. 2 S, after raising the temperature to 130°C, add 2 mol of p-dichlorobenzene. Replace the air in the reactor with carbon dioxide gas 3-5 times, and then seal the reactor. After the reactor is sealed, the temperature rises to 238℃, and keeps it at this temperature for 2h, and when the temperature drops to 130℃, add 0.1mol / molNa 2 S's industria...

Embodiment 2

[0026] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 125℃, and the input holding temperature is 125℃. Equipped with three layers of 18cm / layer 5 angstrom molecular sieve water absorption column. After the molecular sieve absorbs water, the molar ratio of sodium sulfide to water in the sodium sulfide solution becomes 1:1.3, then use 4.5mol / molNa 2 The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, and directly flows into the 2L autoclave, and then the molar mass of NaOH is 0.2mol / molNa in the reactor. 2 S, after raising the temperature to 135°C, add 2 mol of p-dichlorobenzene. Replace the air in the reactor with carbon dioxide gas 3-5 times, and then seal the reactor. After the reactor is closed, the temperature rises to 240℃, and keeps it at this temperature for 2.5h, and when the temperature drops to 135℃, add 0.04mol / molNa 2 S's indust...

Embodiment 3

[0028] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 130℃, and the input holding temperature is 130℃. Equipped with three layers of 18cm / layer 5 angstrom molecular sieve water absorption column. After the molecular sieve absorbs water, the molar ratio of sodium sulfide to water in the sodium sulfide solution becomes 1:1.5, then use 4.5mol / molNa 2 The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, and directly flows into the 2L autoclave, and then the molar mass of NaOH is 0.3mol / molNa in the reactor. 2 S, after raising the temperature to 140°C, add 2 mol of p-dichlorobenzene. Replace the air in the reactor with carbon dioxide gas 3-5 times, and then seal the reactor. After the reactor is sealed, the temperature rises to 242℃, and keeps it at this temperature for 3h, and when the temperature drops to 140℃, add 0.05mol / molNa 2 S's industri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com