Preparation method of low-cost polyphenylene sulfide

A polyphenylene sulfide, low-cost technology, applied in the field of low-cost polyphenylene sulfide preparation, can solve the problems of low molecular weight of PPS, poor batch stability, harsh synthesis conditions, etc., achieve no competitive advantage, improve Degree of polymerization and various mechanical properties, reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Before putting into production, analyze the purity of p-dichlorobenzene, sodium sulfide, N-methylpyrrolidone, sodium hydroxide, and catalyst to avoid affecting the later production.

[0045] Taking the input amount of 100Kg p-dichlorobenzene as an example, proceed as follows:

[0046] (1) Sodium sulfide feeding:

[0047] Before charging, open the exhaust valve of the dehydration kettle leading to the tail gas treatment device to release the pressure in the dehydration kettle.

[0048] In the warehouse, transfer the 52Kg whole package of flaky industrial pure sodium sulfide to the dehydration reaction workshop by trolley, lift it to the floor where the unpacking room is located, and transport it to the airtight and ventilated unpacking room, unpack the sodium sulfide and put it into the feeding hopper In, add 2.5kg sodium hydroxide at the same time, sodium sulfide and sodium hydroxide are unloaded in the dehydration still by feeding hopper;

[0049] N-methylpyrrolidone...

Embodiment 2

[0074] According to the operation steps described in Example 1, repeat 3 times, the average molecular weights of the polyphenylene sulfide obtained 3 times are: 25880, 25650, 25850, the molecular weight is high and relatively stable, indicating that the method has good stability and reproducibility High stability, completely solved the problem of unstable products and low molecular weight of traditional craft products; the quality of the final polyphenylene sulfide were: 60.3Kg, 61.2Kg, 60.4Kg, the theoretical output was 72.070Kg, repeated operations 3 times The lowest yield reaches 83.67%, and the conversion rate is high.

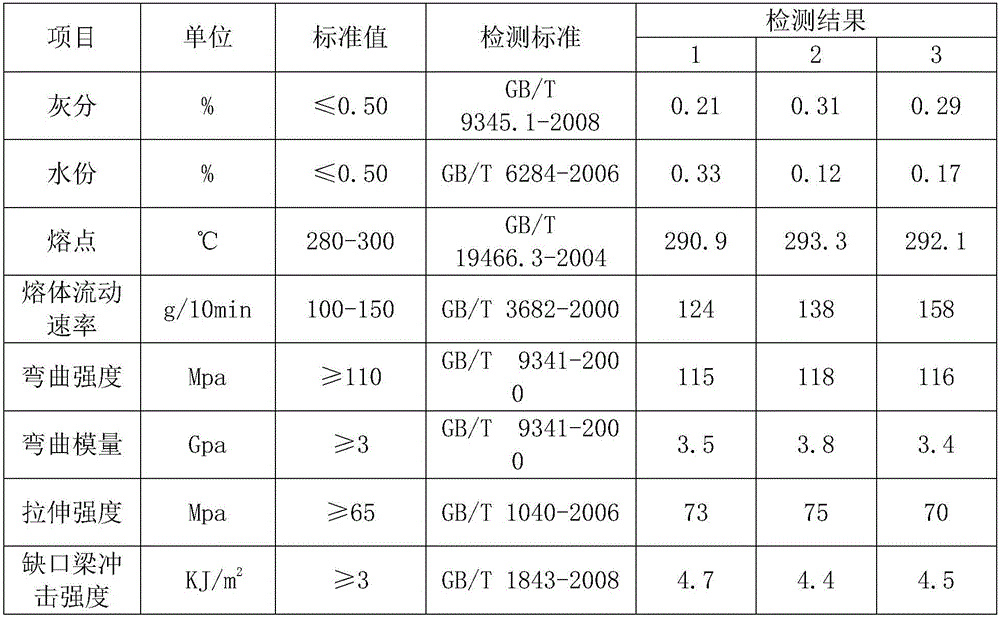

[0075] The physical properties of the polyphenylene sulfide obtained by repeating the operation three times are shown in Table 1:

[0076] Table 1 Physical properties of polyphenylene sulfide

[0077]

[0078] It can be seen from Table 1 that the polyphenylene sulfide prepared by the method of the present invention has excellent mechanical properties a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com