Coating-grade polyphenylene sulfide (PPS) resin and preparation method thereof

A polyphenylene sulfide resin and coating technology, which is applied in the production and synthesis process of polymer materials, can solve the problems of low toughness, high brittleness, and easy cracking of the coating, and achieve the effect of increasing toughness and bonding strength and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

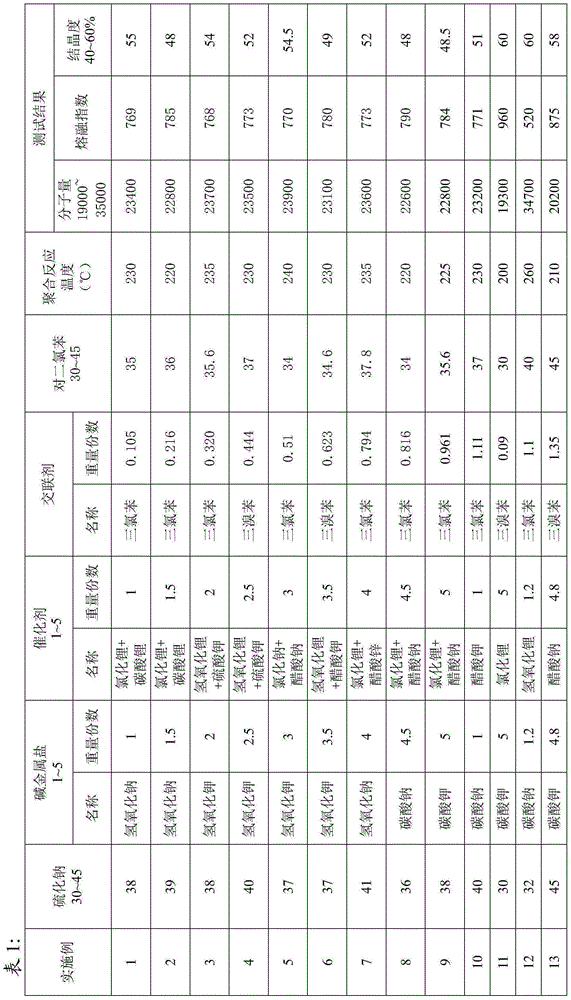

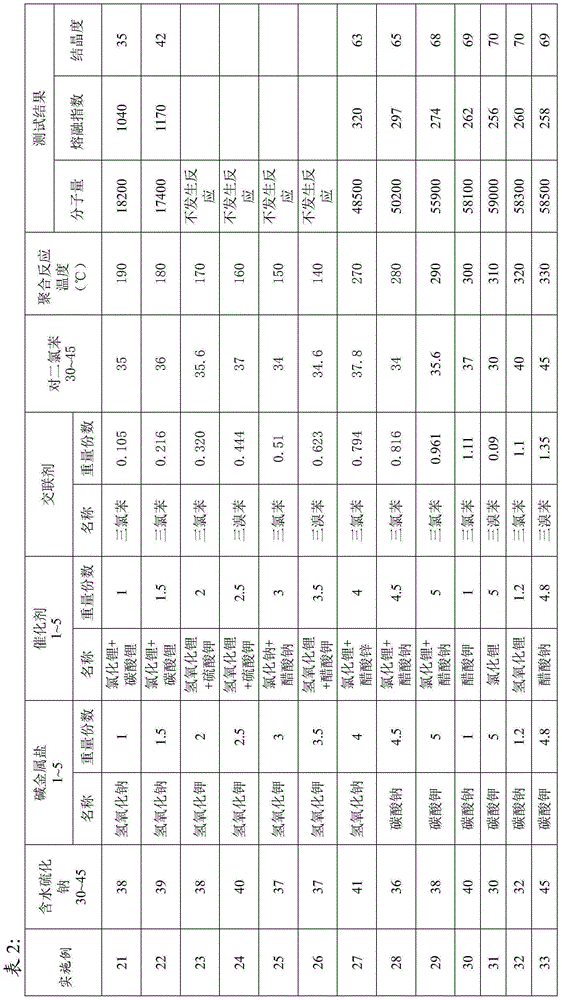

Examples

Embodiment 1

[0014] In a 100-liter reaction kettle, add 19 kg of sodium sulfide, 0.5 kg of sodium hydroxide (alkali metal salt), and 30 kg of NMP solvent, heat up to 150-200° C. after mixing, and dehydrate for 1-3 hours to obtain a mixture. Then, add 25 kilograms of NMP solvents, 0.2 kilograms of trichlorobenzene (crosslinking agent), 0.2 kilograms of lithium chloride and the mixture (catalyst) of sodium carbonate, 17.5 kilograms of p-dichlorobenzenes in reactor again, reactor is heated up to 220~250°C, keep warm for 3 hours, and carry out polymerization reaction. Finally, the polymerized substance is subjected to processes such as precipitation and separation to remove the NMP solvent to obtain a coating-grade polyphenylene sulfide resin.

[0015] It is determined that the molecular weight of the coating-grade polyphenylene sulfide resin is 23400, the melt index is 769, and the crystallinity is 50%.

[0016] It is measured by an electron microscope that about 10-20% of the linear molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com