In2O3@ZnIn2S4 nanosheet material and preparation method and application thereof

A nanosheet and reaction technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve the problem of low photogenerated charge transport and separation efficiency, low photocatalytic performance, long processing time, etc. problems, to achieve the effect of simple operation, high degradation efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Following the above technical solution, this embodiment provides 3D / 2D In 2 o 3 @ZnIn 2 S 4 Nanosheet materials, preparation methods and applications. Include the following steps:

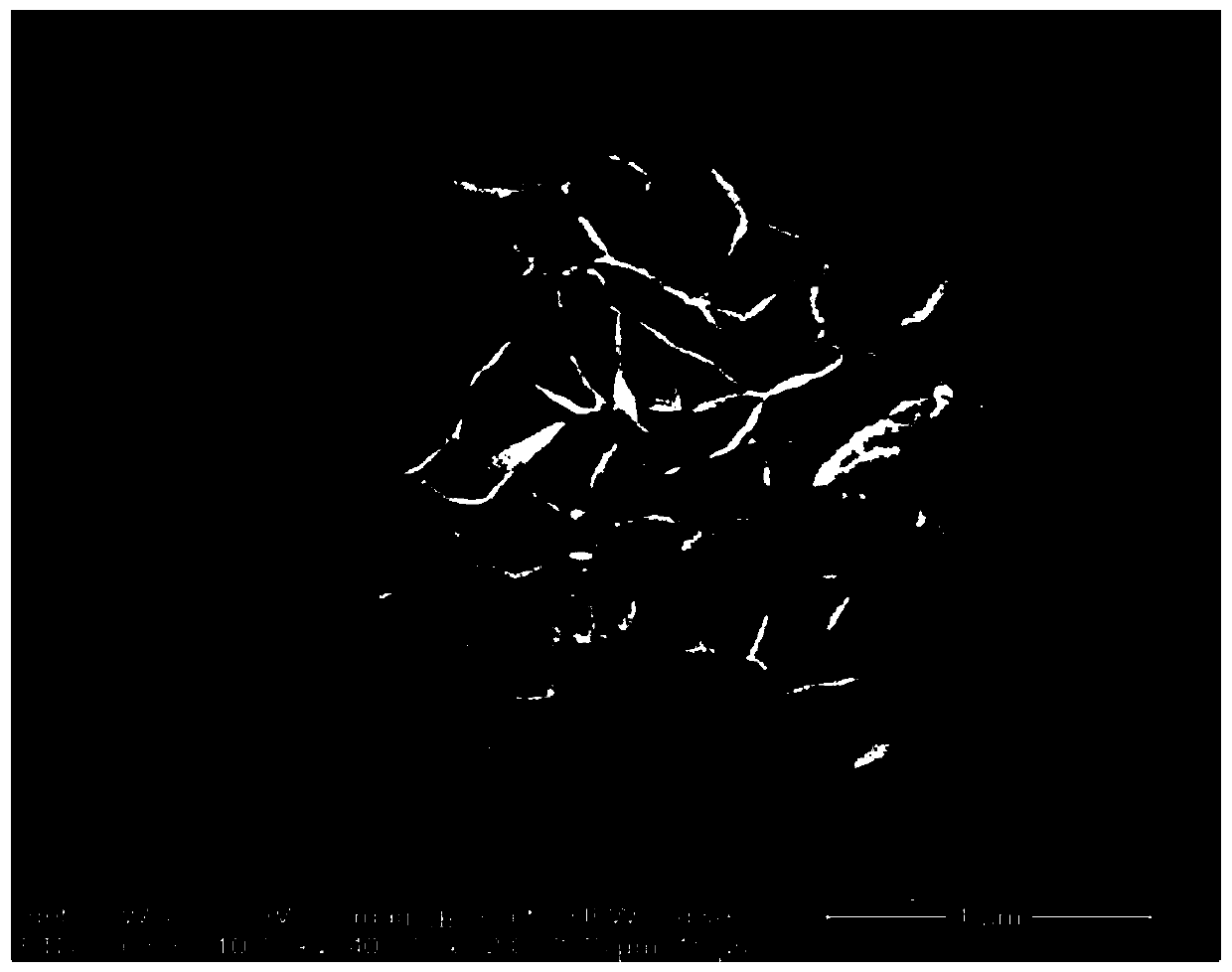

[0029] Add 0.075g of In 2 o 3 (0.2 mmol) was dissolved in 20 mL of deionized water at pH 2.5 and stirred vigorously at room temperature for 0.5 h. Then 0.068g ZnCl 2 (0.4mmol), 0.147g InCl 3 4H 2 O (0.4mmol) and 0.075g thioacetamide (TAA) (1mmol) were added to the above solution and stirred vigorously for 5 minutes; then, the above mixture solution was transferred to a water bath at 80°C and stirred for 2 hours; after cooling to room temperature, The samples were collected by centrifugation, washed three times with deionized water and ethanol, and dried in a drying oven at 60 °C for 2 h to obtain 3D / 2D In 2 o 3 @ZnIn 2 S 4 nanosheet material. The electron microscope image of the material is shown in figure 1 shown. Zn 2 S 4 Nanosheets are attached with In 2 o 3 , the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com