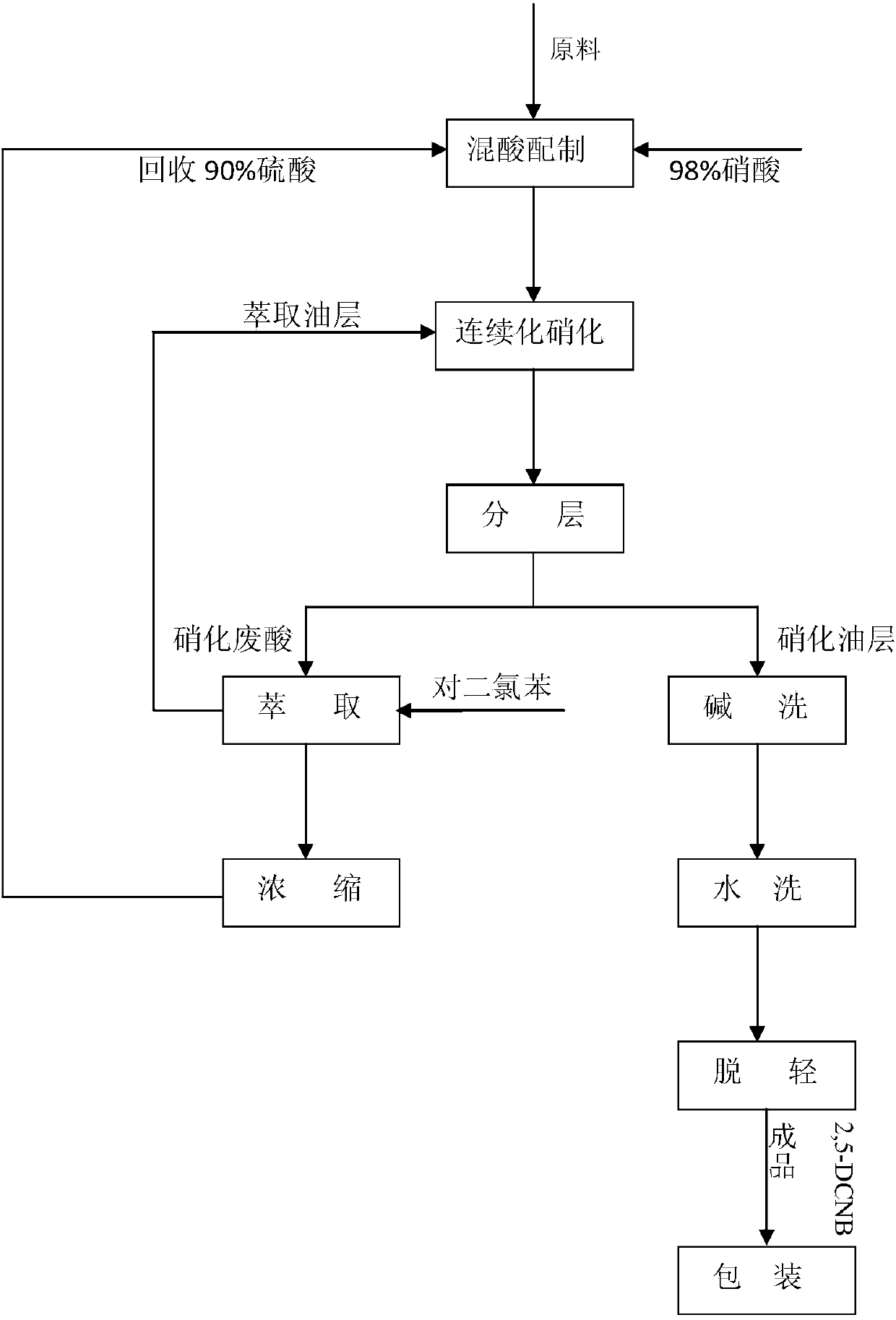

Method capable of recycling acids for preparing 2,5-dichloronitrobenzene (DCNB) through continuous nitration

A technology of dichloronitrobenzene and p-dichlorobenzene, which is applied in the field of continuous nitration to prepare 2,5-dichloronitrobenzene, can solve the problems that waste acid cannot be used mechanically, product quality and yield fluctuations, etc., and achieve large production capacity , stable product quality and yield, and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

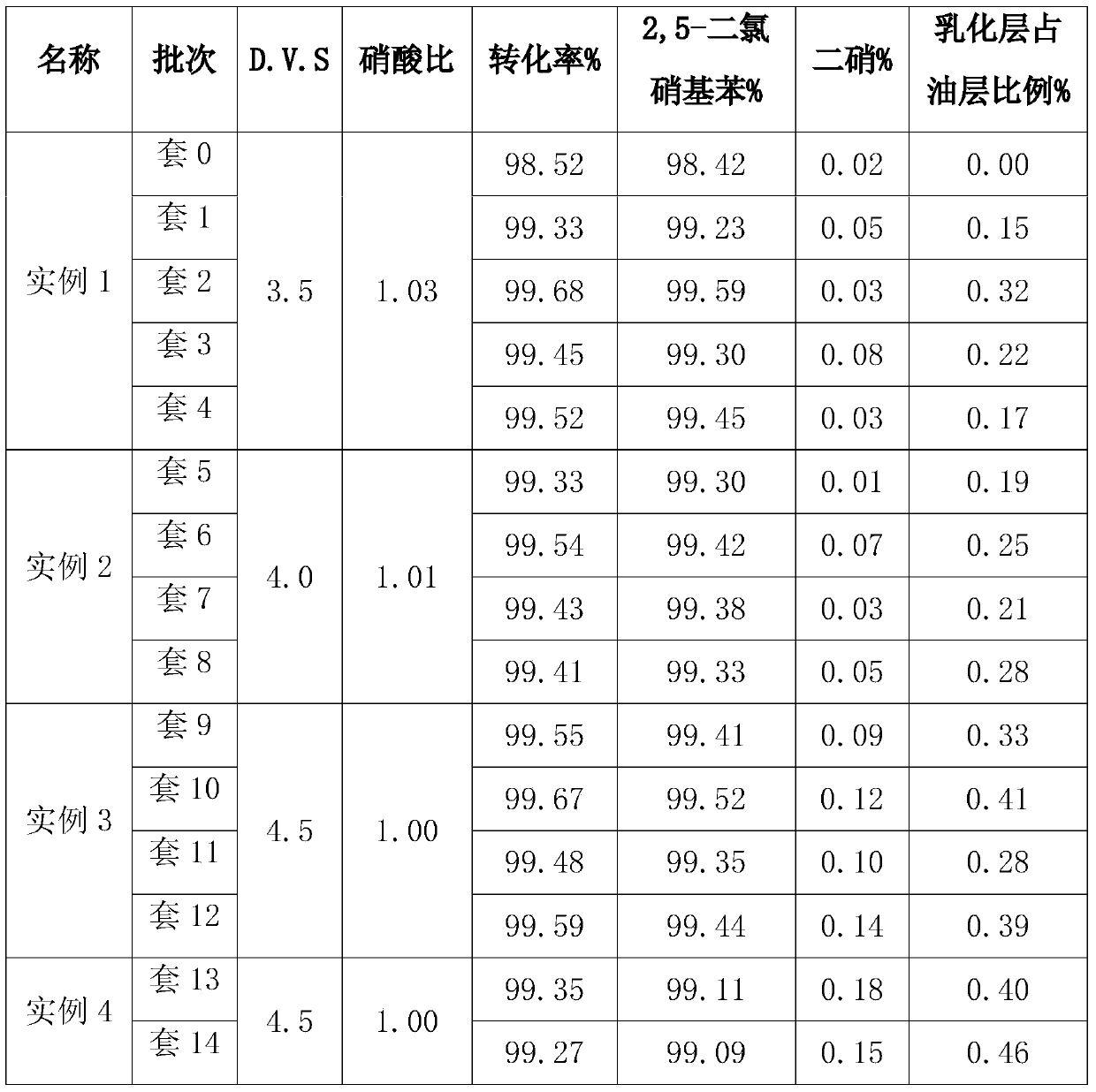

[0022] Add 535.16g of 90% sulfuric acid to a 1000ml glass reactor, control the stirring speed, slowly add 288.18g of 98% nitric acid dropwise to prepare a mixed acid, and control the temperature during the dropping of nitric acid to ≤40°C. The weight ratio of sulfuric acid: nitric acid: water in the mixed acid is 58.5:34.3 : 7.2.

[0023] Continuous nitration uses three glass reactors with volumes of 1000ml, 500ml, and 500ml in series, and the effective volume of each kettle is 500ml, 248ml, and 248ml, totaling 996ml. During the process, the D.V.S value is controlled to be 3.5, the nitric acid ratio is 1.03, the temperature of the first-stage reactor is 56-60°C, the residence time is about 3h, the temperature of the second-stage reactor is 60-65°C, the residence time is about 1.5h, and the temperature of the third-stage reactor is 65-70°C The time is about 1.5h. Start feeding to the first-stage reactor, the feed rate of p-dichlorobenzene is 86.68ml / h, and the feed rate of mix...

Embodiment 2

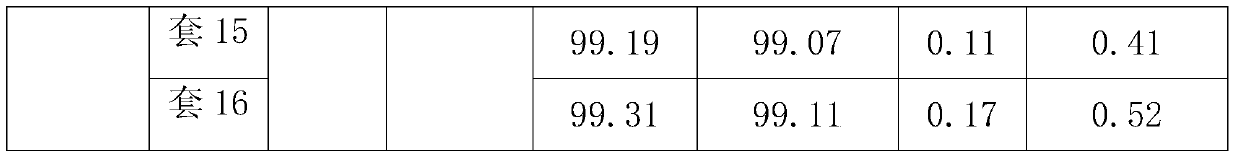

[0028] In Example 1, 4 times of recovering 90% sulfuric acid were used mechanically, and a certain amount of 90% sulfuric acid was added to reach 624.36g, and 262.58g of 98% nitric acid was added dropwise to prepare a mixed acid in which the sulfuric acid: nitric acid: water weight ratio was 63.4:29.0:7.6. Control D.V.S value 4.0 in the process, nitric acid ratio 1.01, p-dichlorobenzene feed rate 80.55ml / h, mixed acid feed rate 85.45ml / h, other conditions are the same as embodiment 1, spent acid is applied mechanically 4 batches under this scheme. The experimental results are shown in Table 1.

Embodiment 3

[0030] In Example 2, 8 times of recovery of 90% sulfuric acid were applied mechanically, and a certain amount of 90% sulfuric acid was added to reach 716.34g, and 238.78g of 98% nitric acid was added dropwise to prepare a mixed acid in which the weight ratio of sulfuric acid: nitric acid: water was 67.5:24.5:8.0. Control D.V.S value 4.5 in the process, nitric acid ratio 1.00, p-dichlorobenzene feed rate 73.98ml / h, mixed acid feed rate 92.02ml / h, other conditions are the same as embodiment 1, waste acid is applied mechanically 4 batches under this scheme. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com