Process for synthesizing low-chlorine polyphenylene sulfide resin

A technology of polyphenylene sulfide resin and synthesis process, which is applied in the field of polymer material resin synthesis to achieve the effects of shortening the synthesis time, increasing the reaction speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

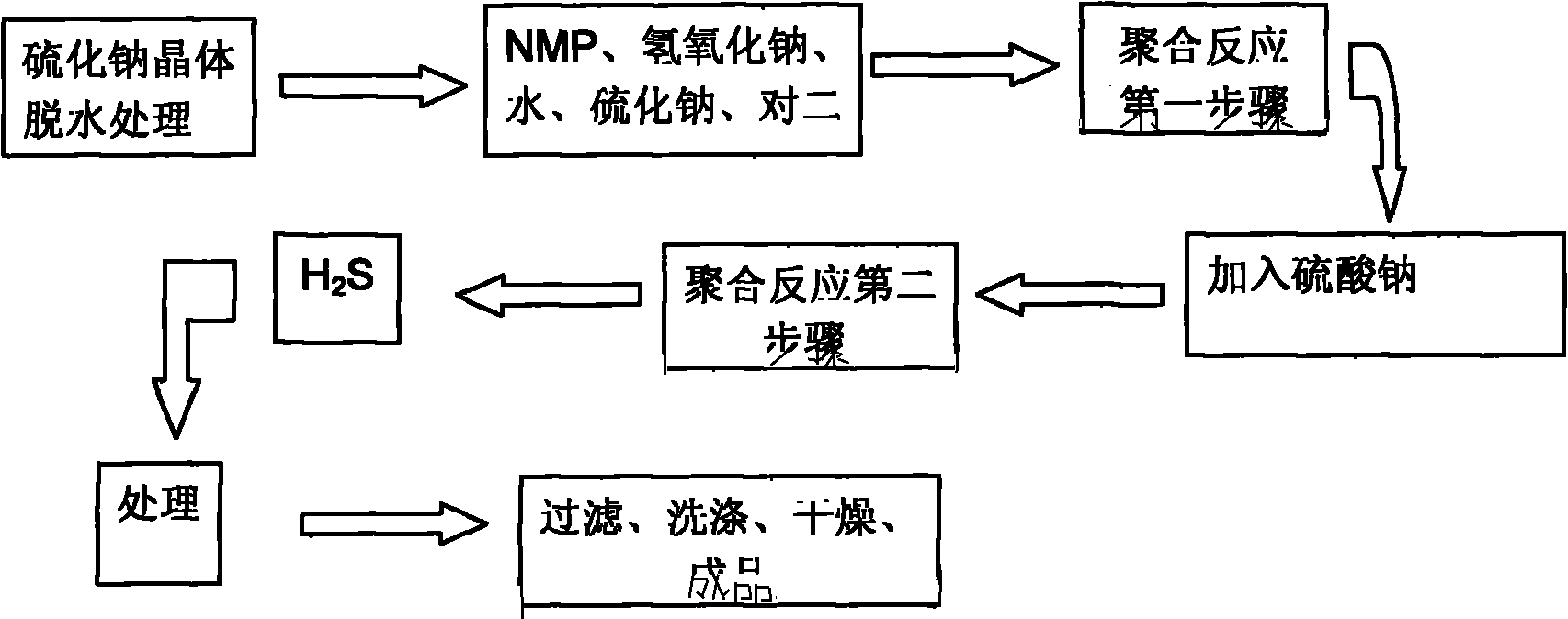

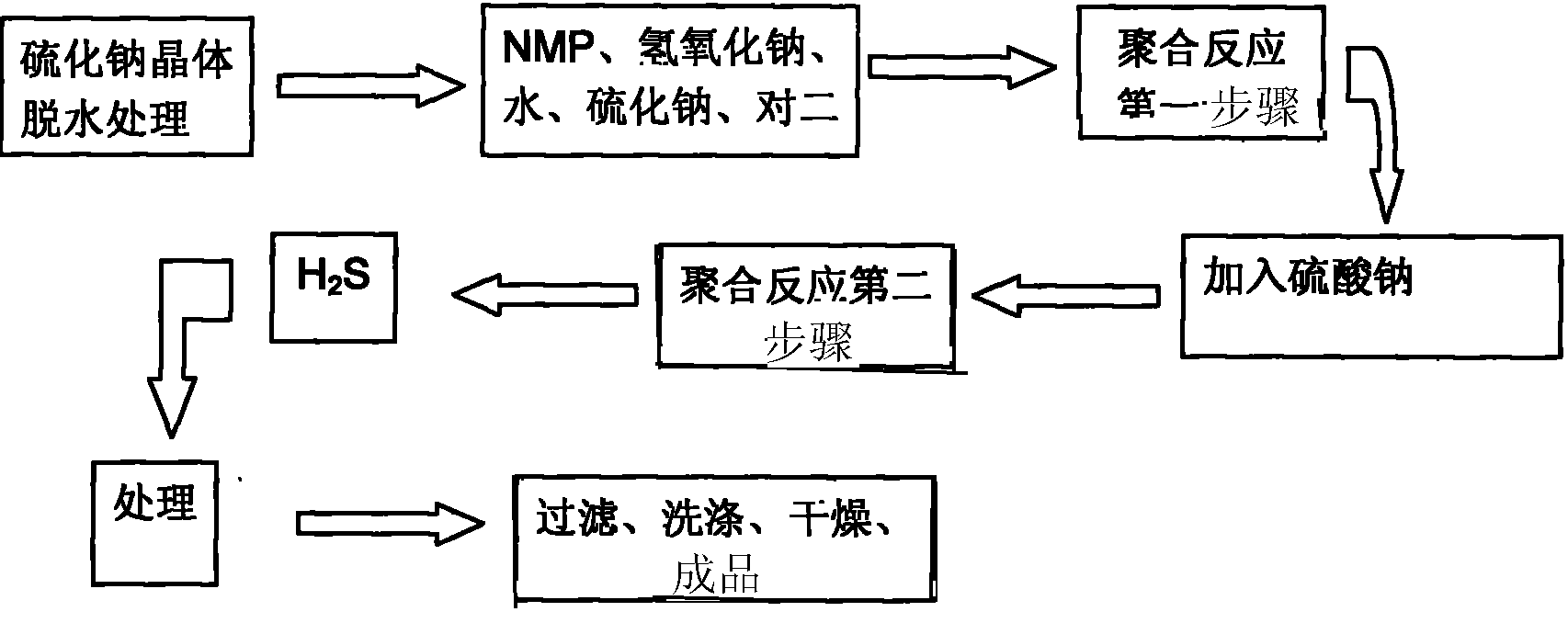

Method used

Image

Examples

Embodiment 1

[0024] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 120°C, and the input insulation temperature is 120°C. Three layers of 18cm / layer 5 angstrom molecular sieve water absorption columns are installed. After the molecular sieve absorbs water, the molar ratio of sodium sulfide and water in the sodium sulfide solution becomes 1:1.2, then use 4.5mol / molNa 2 The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, directly flows into the 2L high-pressure reactor, and then the molar mass of NaOH is added to the reactor with a molar mass of 0.1mol / molNa 2 S, after raising the temperature to 130°C, add 2mol of p-dichlorobenzene. Then replace the air in the reactor with carbon dioxide gas 3-5 times, then seal the reactor, the temperature rises to 238°C, and keeps at this temperature for 2h, and when the temperature drops to 130°C, add 0.1mol / molN...

Embodiment 2

[0026] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 125°C, and the input holding temperature is 125°C. Three layers of 18cm / layer 5 angstrom molecular sieve water absorption columns are installed. After the molecular sieve absorbs water, the molar ratio of sodium sulfide and water in the sodium sulfide solution becomes 1:1.3, then use 4.5mol / molNa 2The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, directly flows into the 2L high-pressure reactor, and then the molar mass of NaOH is added to the reactor with a molar mass of 0.2mol / molNa 2 S, after raising the temperature to 135°C, add 2mol of p-dichlorobenzene. Then replace the air in the reactor with carbon dioxide gas 3-5 times, then seal the reactor, the temperature rises to 240°C, and keeps at this temperature for 2.5h, and when the temperature drops to 135°C, add 0.04mol / molNa...

Embodiment 3

[0028] In a 1L dehydration kettle, add sodium sulfide (Na 2 S.5H 2 O) 2.0mol, at 99.99% CO 2 Under the protection of gas, the temperature is heated to 130°C, and the input holding temperature is 130°C. Three layers of 18cm / layer 5 angstrom molecular sieve water absorption columns are installed. After the molecular sieve absorbs water, the molar ratio of sodium sulfide and water in the sodium sulfide solution becomes 1:1.5, then use 4.5mol / molNa 2 The NMP solvent of S is added from the top of the water absorption column of the molecular sieve, directly flows into the 2L high-pressure reactor, and then the molar mass of NaOH is 0.3mol / molNa 2 S, after raising the temperature to 140°C, add 2mol of p-dichlorobenzene. Replace the air in the reactor with carbon dioxide gas 3-5 times, and then seal the reactor, the temperature rises to 242°C, and keeps at this temperature for 3 hours, and when the temperature drops to 140°C, add 0.05mol / molNa 2 Industrial Grade Na of S 2 SO 4 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com