Polyphenylene sulfide with low chlorine content, preparation method of polyphenylene sulfide, resin composition and formed body

A technology of polyphenylene sulfide and chlorine content, applied in the field of polyphenylene sulfide with low chlorine content and its preparation, can solve the problems of environmental protection, processing performance and mechanical properties, etc., which is conducive to safe production and simple preparation method , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

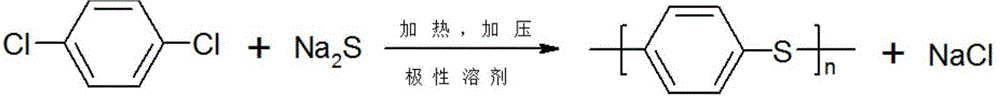

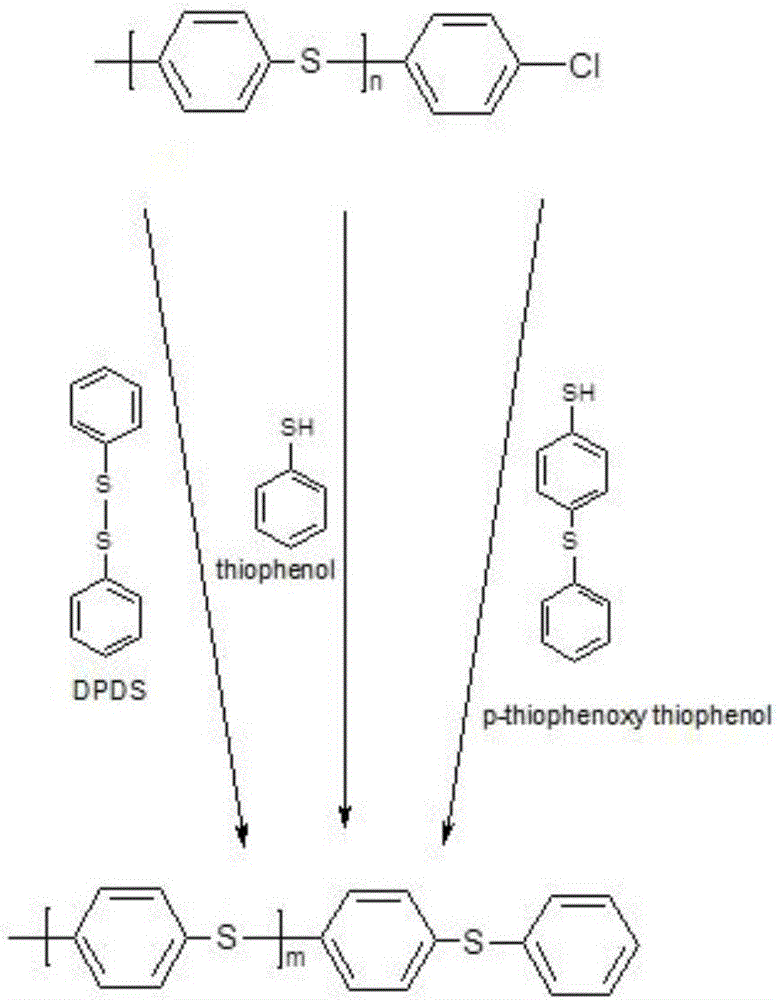

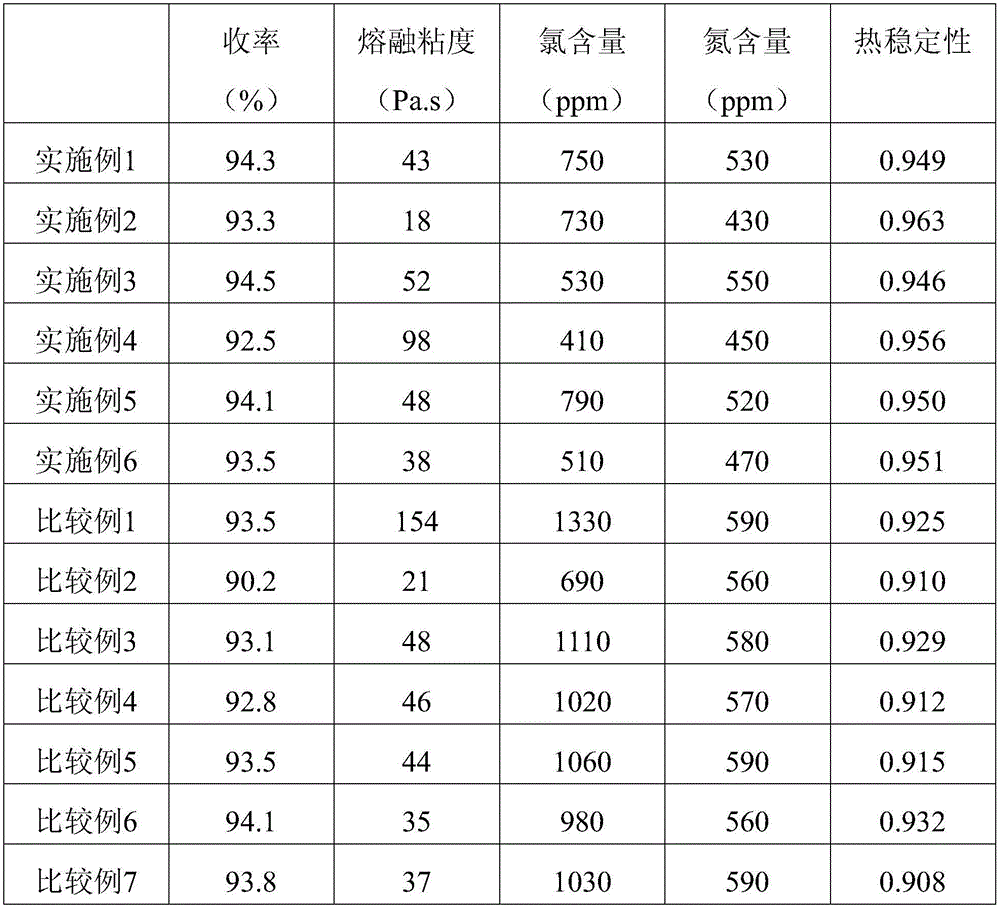

[0064] In the first embodiment, the present invention provides a polyphenylene sulfide resin having a low chlorine content. The polyphenylene sulfide resin of the present invention is obtained through the polycondensation reaction of the sulfur-containing compound and p-dichlorobenzene, and then the end-blocking reaction of the terminal regulator 4-phenylthio-benzenethiol. Preferably, the polycondensation reaction is carried out in the presence of polycondensation assistants.

[0065] sulfur compounds

[0066] The sulfur-containing compound used in this embodiment is not particularly limited in principle, and may be simple sulfur, alkali metal sulfide, alkali metal hydrogensulfide, etc. commonly used in the art. Further, the inventors of the present invention have found that, from the viewpoint of both thermal stability, if the presence of -S-S- in the possible polyphenylene sulfide structure causes a decrease in thermal stability, the sulfide-containing compound in this em...

no. 2 Embodiment approach

[0087] In the second embodiment, the present invention provides a method for preparing polyphenylene sulfide resin with low chlorine content, which includes using sulfur-containing compounds, alkaline substances, and p-dichlorobenzene as raw materials, and using fatty acids as polycondensation aids , 4-phenylthio-benzenethiol (PTT) as the terminal regulator, polycondensation reaction.

[0088] Specifically, the method includes the following steps:

[0089] Step 1: After adding alkaline substances and fatty acids to the solvent, perform dehydration treatment;

[0090] Step 2: adding sulfur-containing compounds to the mixed system of step 1;

[0091] Step 3: Add p-dichlorobenzene to the mixed system of step 2, and carry out polycondensation reaction, add 4-phenylthio-benzenethiol to react in the middle and later stages of polycondensation reaction (such as after the prepolymerization reaction ends), and then Lower the temperature to 155-180°C to obtain a reaction product syste...

no. 3 Embodiment approach

[0115] A third embodiment of the present invention relates to a resin composition and a molded article produced using the resin composition.

[0116] The resin composition of this embodiment contains the polyphenylene sulfide resin obtained in the first embodiment and the second embodiment. In this resin composition, based on different usage purposes, the other resin components are not limited, and may be various engineering plastics and conventional resins having good compatibility with polyphenylene sulfide resin.

[0117] In addition, in the above resin composition, various additives such as flame retardants, weather resistance agents, fillers and other components can also be added as needed to meet the processing and use requirements of the industry, especially the components of the electronic and electrical industry.

[0118] The composite material prepared by using the polyphenylene sulfide resin of the present invention may typically be a fiber-reinforced composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com