Patents

Literature

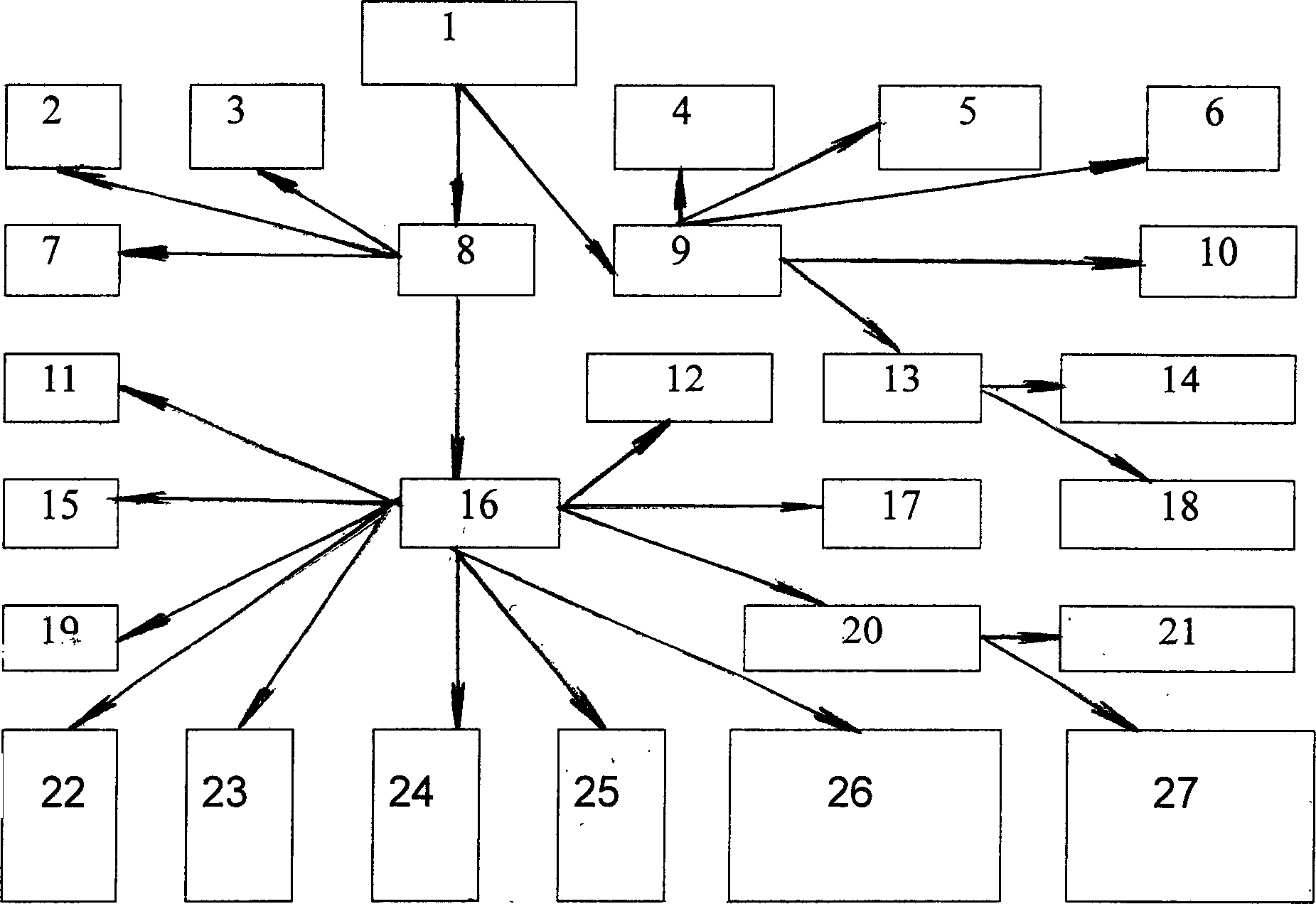

40results about How to "Reduce the amount of nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling nitrogen content in steel by semi-steel smelting

InactiveCN102230051AReduce the amount of nitrogenReduce nitrogen contentManufacturing convertersFoaming agentLow nitrogen

The invention discloses a method for controlling nitrogen content in steel by semi-steel smelting. According to the invention, the method for controlling nitrogen content in steel by semi-steel smelting comprises the following steps of: performing oxygen top blowing by using a converter, performing slag-modifying treatment before tapping, and blocking the slag and tapping. In addition, according to the requirements steel on nitrogen content, different bottom-blowing modes are adopted in the oxygen top blowing process by converter, a foaming agent is added at the last stage of blowing, argon gas is blown to ladles 1 to 3 minutes before tapping, and the soft argon blowing operation is performed on ladles during the tapping step. By adoption of the method provided by the invention, the nitrogen content in steel at the converter end-point can be controlled to be within 11 ppm and the nitrogen increase can be controlled to be between 1ppm to 3 ppm during the tapping step. The method provided by the invention can effectively reduce the nitrogen content at the converter end-point and the nitrogen increase in the tapping step, thereby providing a technical support for the production of low-nitrogen steel and ultra-low nitrogen steel.

Owner:PANZHIHUA IRON AND STEEL +2

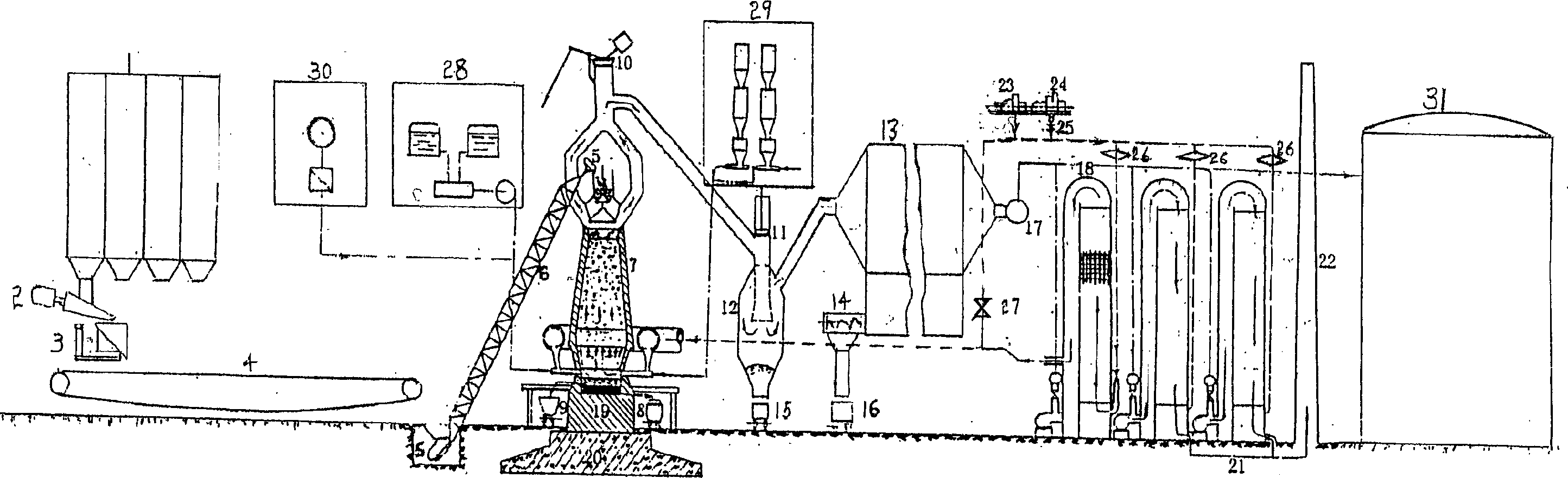

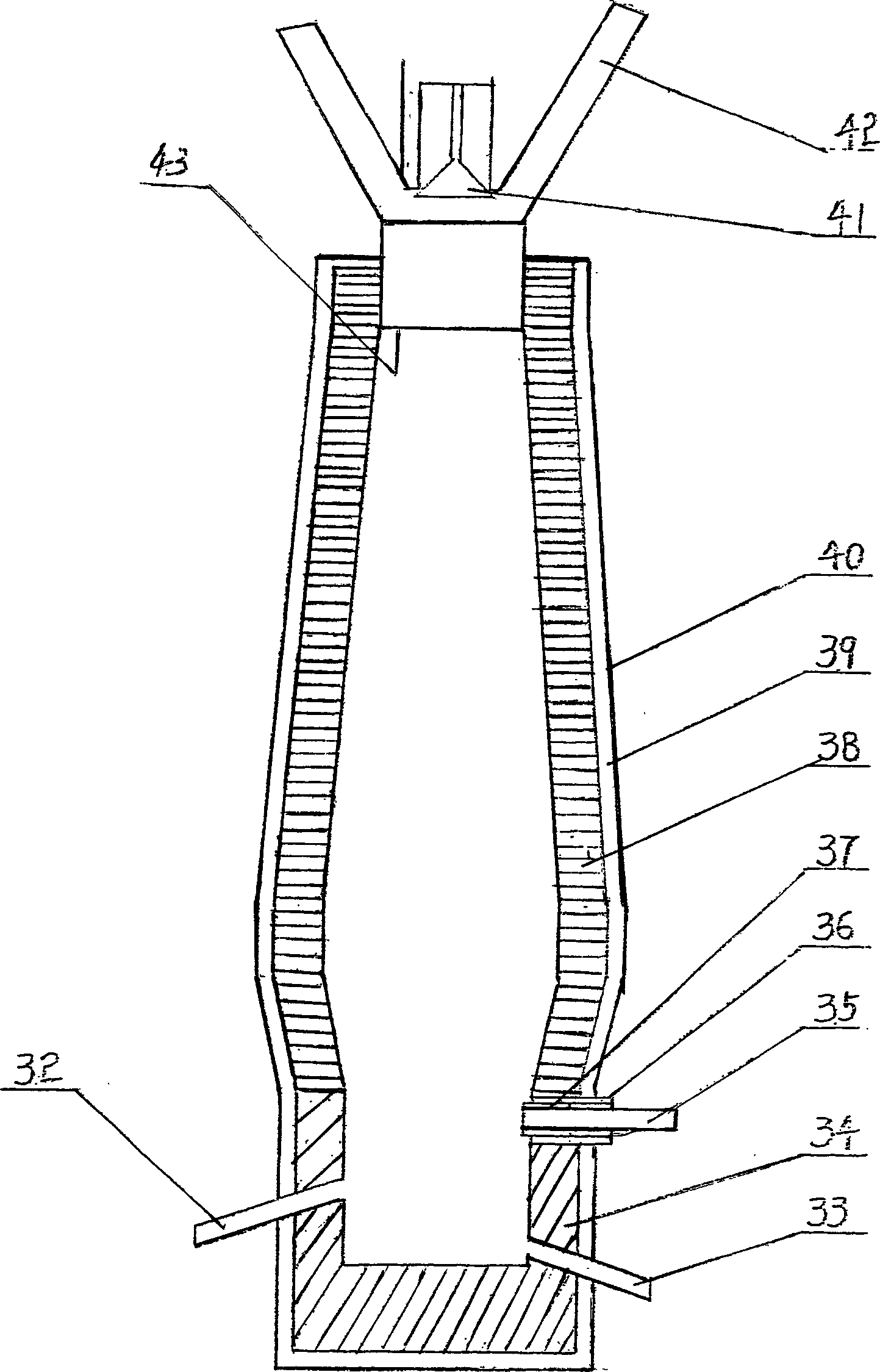

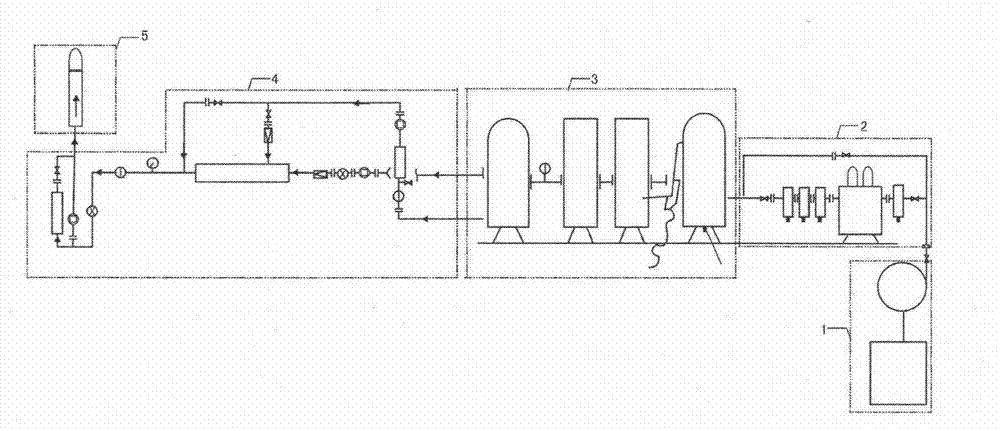

Method and apparatus for preparing calcium carbide by oxygen-fuel blowing of high furnace

InactiveCN1843907AReduce manufacturing costRealize the comprehensive utilization of resourcesChemical industryCalcium carbideFerrosiliconHearth

The invention relates to field of preparing calcium carbide with oxygen jetting in tower furnace. The calcium carbonate is heat decomposed into calcium oxide and reduced to calcium carbide by carbon material by jetting with preheating oxygen or oxygen-enriched air. The device comprises: tower furnace and systems of feeding, charging, oxygen producing, heating air, blasting air, oxygen enriching, jetting, cooling, cleaning and recoverying coal gas and recovering calcium carbide and ferrosilicon. The ration between said furnace height and furnace hearth diameter is less than or equal to 3.5, and diameter ratio between furnace hearth and furnace hearth is 0.8-1.1. The invention is to produce calcium carbide of 80%, the proportioning of raw material is lime carbonate: coke: fluorite =(1.2-2.0): (1.5-4.0): (0.039-0.046); jetting material is coal powder, light oil or natural gas; relative oxygen-enriched air amount, the xygen-enriched rate is 9-39%, and prepares side products of calcium carbide of more than 65%, ferrosilicon more than or equal to 54% and carbon monoxide of more than or equal to 54% at high temperature. The invention is characterized by energy saving, high quality and environmental protection.

Owner:岳书才

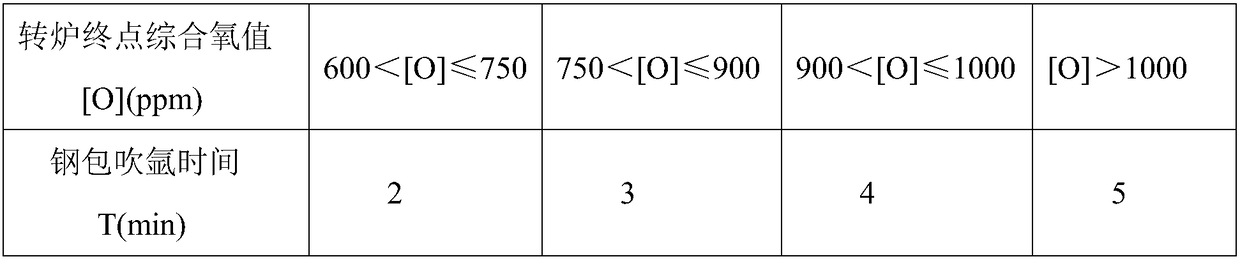

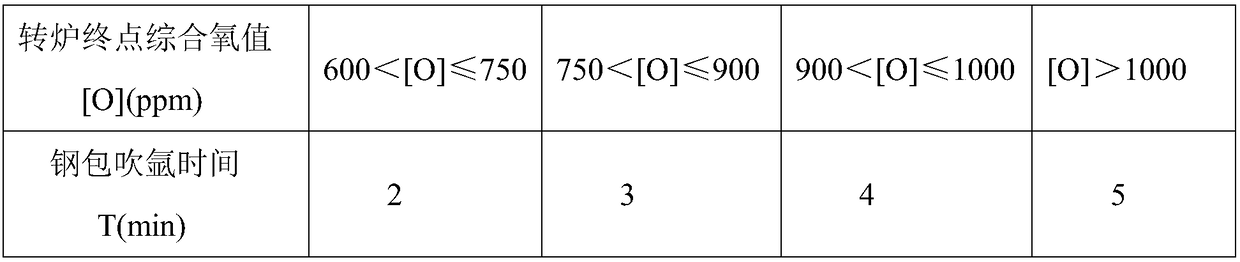

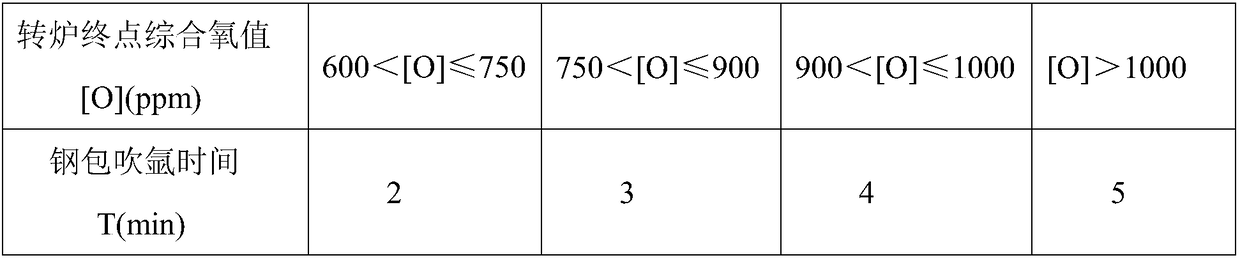

Method for conducting deoxidization and nitrogen control on output steel of semisteel steelmaking converter

ActiveCN104988273AGuaranteed performanceReduce consumptionManufacturing convertersSteelmakingFerrosilicon

The invention belongs to the technical field of metallurgy, and particularly relates to a method for conducting deoxidization and nitrogen control on output steel of a semisteel steelmaking converter. The method includes the steps that when the oxygen activity of molten steel at the end point is larger than or equal to 800 ppm and steel is output by one fourth to one third, carburant is adopted for preliminary deoxidization; after steel is output by one third, silicon iron is adopted for deoxidization; after steel is completely output, an aluminum wire is adopted for thorough deoxidization on a blowing-argon-behind-converter platform; when the oxygen activity of molten steel at the end point is larger than or equal to 500 ppm and smaller than 800 ppm and after steel is output by one third, carburant is adopted for preliminary deoxidization; it is ensured that the oxygen activity of molten steel is larger than 500 ppm after steel is output, and the aluminum wire is adopted for thorough deoxidization on the blowing-argon-behind-converter platform after steel is completely output. By means of the process, the deoxidizing material consumption can be effectively lowered, production cost is reduced, and resources are saved; meanwhile, the nitrogen increase volume in the steel output process can be reduced, the nitrogen increase can be stably controlled within 5 ppm, and steel performance is ensured.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for obtaining low-nitrogen steel by reducing nitrogen content in steel in electric furnace steelmaking process

ActiveCN112981038AReduce nitrogen uptakeGood emulsificationElectric furnaceSteelmakingElectric arc furnace

The invention relates to a method for obtaining low-nitrogen steel by reducing nitrogen content in steel in an electric furnace steelmaking process. The method comprises the following steps that in the smelting process of an electric arc furnace, a mode of mixed smelting of waste steel and molten iron is adopted, a rapid slagging technology is assisted, and silicon iron is added in the tapping process to carry out weak deoxidation on molten steel; in the LF refining procedure, a high-temperature-resistant material sealing sleeve is installed at an electrode opening, refining synthetic slag is added in the smelting process for slagging, and the appropriate bottom blowing argon flow is adjusted; in the VD vacuum treatment process, a high vacuum degree, treatment time prolonging and bottom blowing argon flow increasing strong stirring mode is adopted; and in the continuous casting process, protective pouring and immersion type sleeve sealing measures are adopted. According to the method, the nitrogen content in the steel is obviously reduced on the basis of molten steel nitrogen absorption and denitrification mechanisms and in combination with the operation characteristics of all the procedures, the method is easy to operate, nitrogen control of the whole process in the electric furnace steelmaking process is stable, and it can be effectively guaranteed that the nitrogen content in a finally obtained product is smaller than 30ppm.

Owner:UNIV OF SCI & TECH BEIJING

Method for controlling nitrogen increasing of converter tapping molten steel

The invention provides a method for controlling nitrogen increasing of converter tapping molten steel. When the tapping carbon weight percent is less than 0.10%, the oxygen content is controlled to 300-500ppm; when the tapping carbon weight percent is 0.10-0.20%, the oxygen content is controlled to 100-250ppm; when the tapping carbon weight percent is more than 0.20%, the oxygen content is controlled to 50-100ppm; converter after-deoxidation alloys, namely non-deoxidation alloys, weak-deoxidation alloys and strong-deoxidation alloys are added in turn, thus increasing the oxygen content of steel in the early stage of tapping; and Si-Fe-Ba-Ca and an aluminum-containing material are added 1min before the converter tapping. By adopting the method provided by the invention, the nitrogen increasing amount of the tapping process can be effectively reduced and the nitrogen increasing amount of molten steel in the tapping process is decreased from 6-10ppm to 2ppm or less. Therefore, the quality of the finished steel can be increased and the demands of users on the operational performance can be met.

Owner:ANGANG STEEL CO LTD

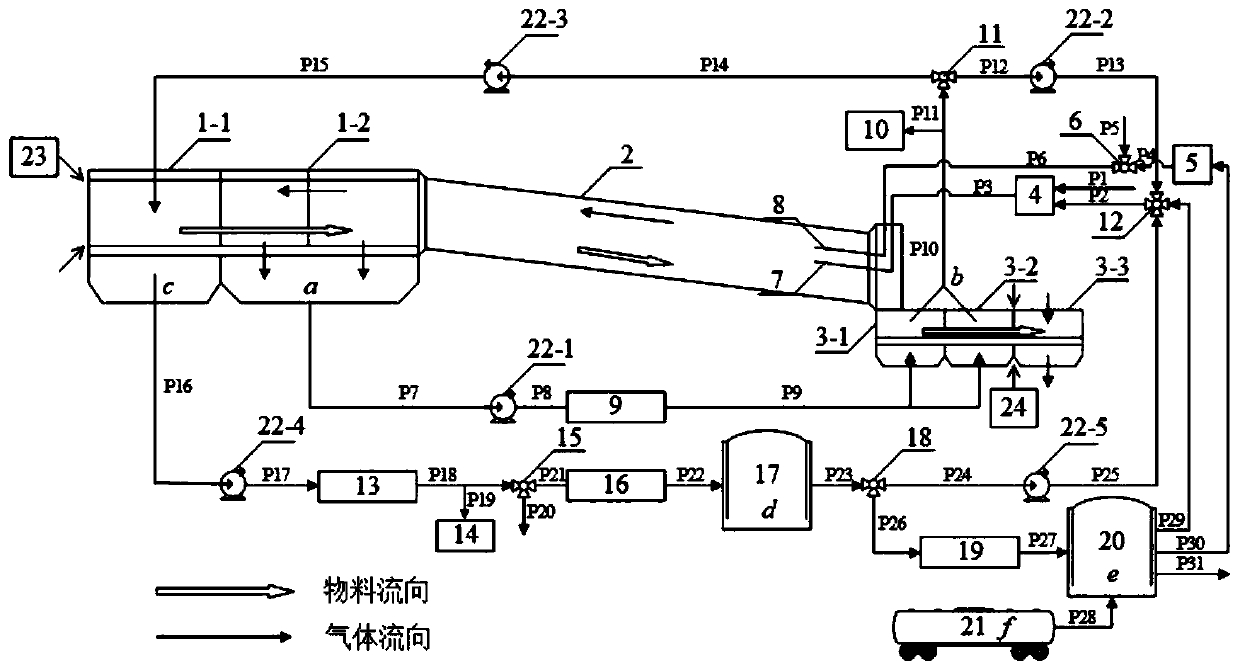

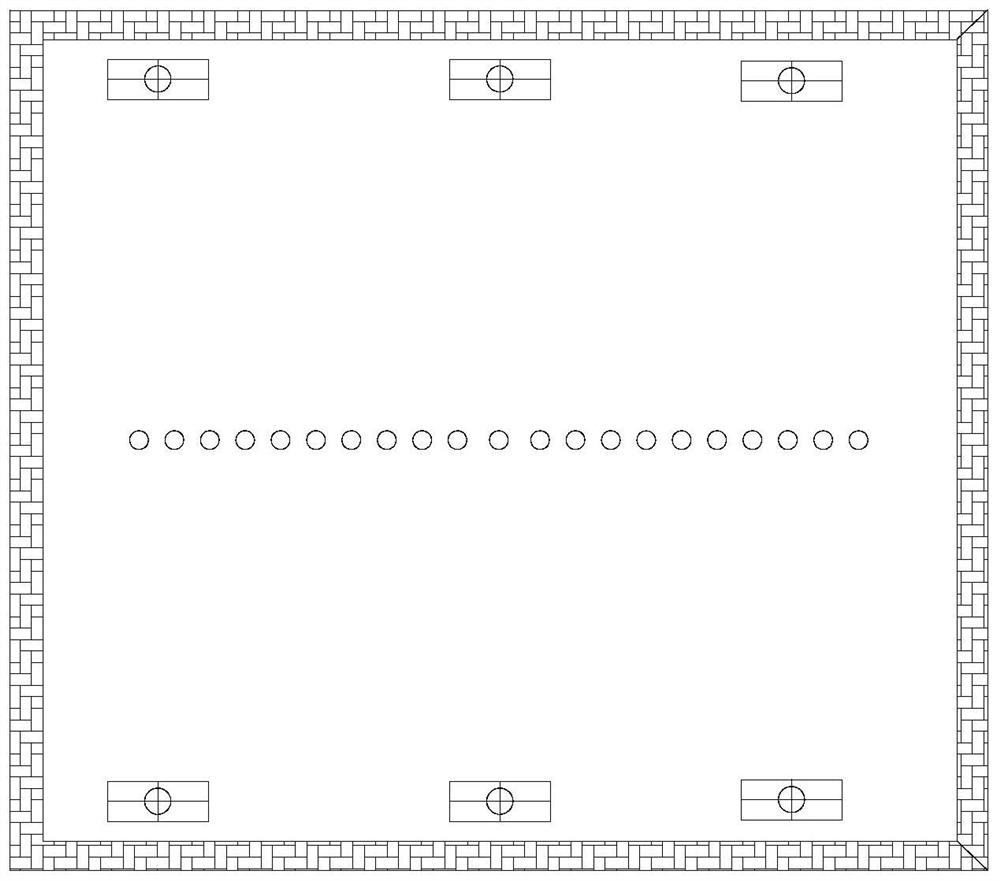

Pellet production technology and preparation system based on exhaust circulation O2-CO2 combustion supporting

ActiveCN109813129AReduce inputReduce generationCarbon compoundsRotary drum furnacesHigh concentrationNitrogen

The invention discloses a pellet production technology and preparation system based on exhaust circulation O2-CO2 combustion supporting, and belongs to the field of pellet environment-friendly efficient preparation production in the ferrous metallurgy process. The physical heat of exhaust in the production process is used for drying and preheating of pellets, and the exhaust containing high-concentration CO2 is directly mixed with or mixed with industrial pure oxygen after being purified to serve as combustion-supporting gas of fuel. According to the pellet production technology and preparation system, the waste heat of the exhaust is sufficiently utilized, and the heat utilization efficiency of the pellet preparation system is improved; approximate zero input of nitrogen of the pellet preparation system is achieved, and the generation amount of NOx in the production process is decreased from the source; and the exhaust containing the high-concentration CO2 can be used for preparing industrial grade / food grade CO2 with low cost, and a CO2 recycling and emission reduction approach is provided.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for maintaining and replacing natural gas pipeline

InactiveCN110067910ANormal deliveryReduce the amount of nitrogenPipe elementsNon-disconnectible pipe-jointsEngineeringProcess engineering

The invention discloses a method for maintaining and replacing a natural gas pipeline. The method comprises the following steps of step 1, closing an upstream clamping plate valve and a downstream clamping plate valve of an accident section and emptying; step 2, connecting a bypass pipeline; step 3, welding an open hole for short connection; step 4, downwards putting a first layer of isolating bag; step 5, downwards putting a rectangular ventilator; step 6, sealing the open hole; step 7, downwards putting a second layer of isolating bag; step 8, downwards putting a rectangular ventilator; step9, cutting the pipeline; and step 10, taking out the isolating bags and welding to replace the pipeline. According to the method, the first isolating bag and the second isolating bag are arranged toblock the natural gas in the upstream and downstream pipelines of the accident section, so that the blocking property is improved, the safe pipeline replacement and maintenance operation of the accident section can be guaranteed, the liquid nitrogen consumption can be greatly reduced, the normal transmission of the natural gas is guaranteed, and the production operation is not affected.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

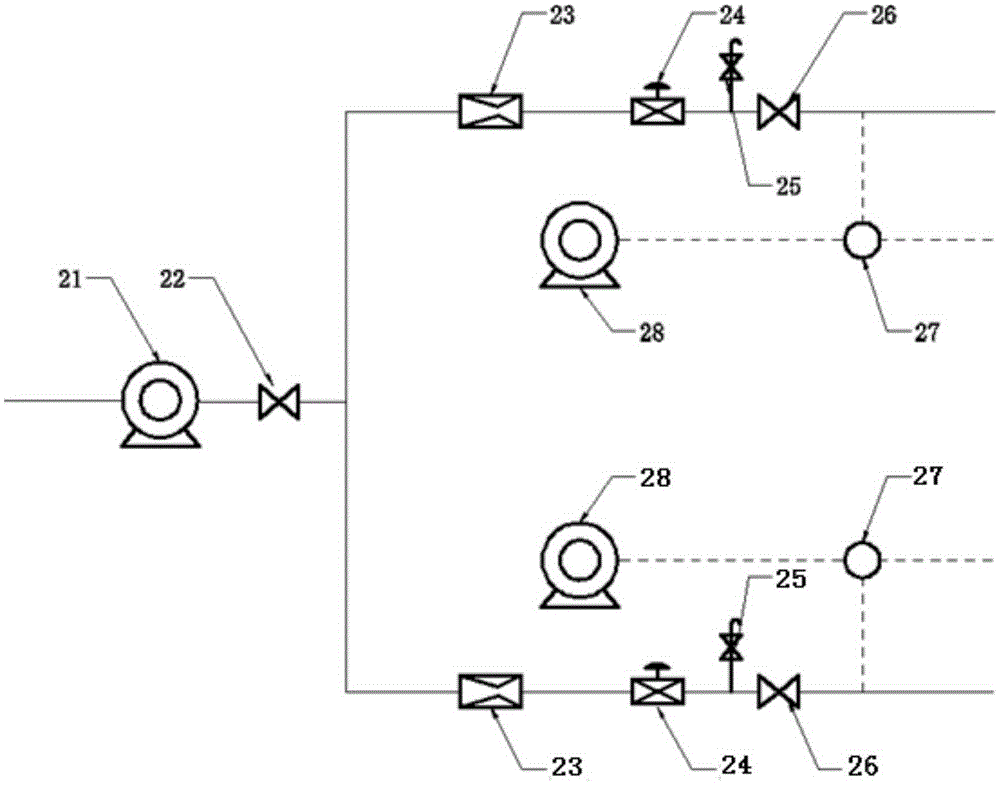

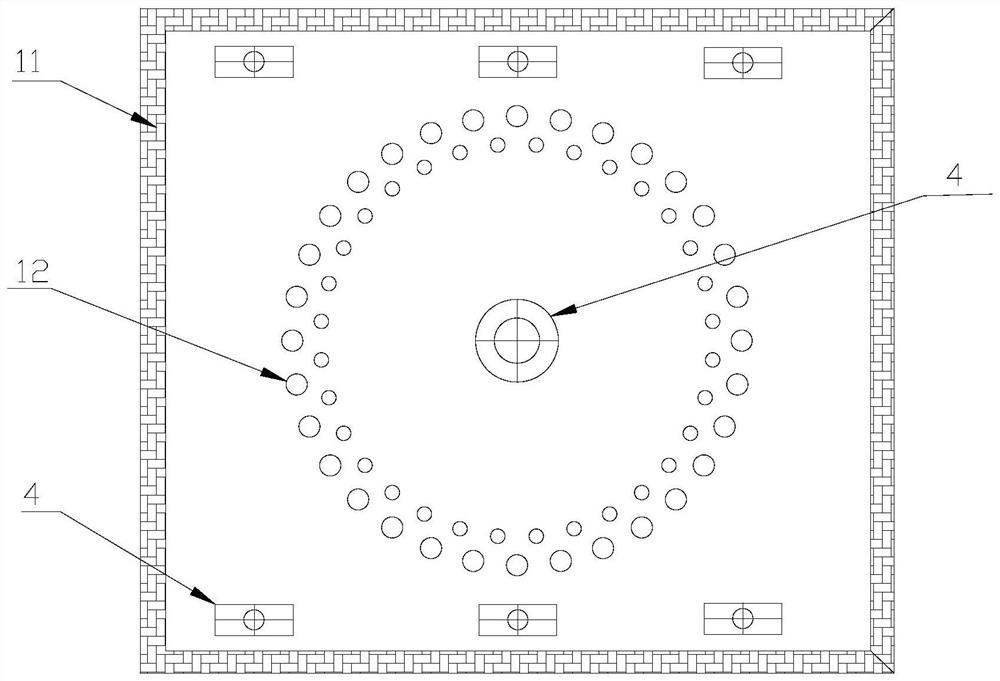

Pyrolysis and gasification garbage incinerator adopting oxygen enriched combustion technique

ActiveCN105351942AHigh calorific valueImprove combustion conditionsIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberOxygen enrichment

The invention discloses a pyrolysis and gasification garbage incinerator adopting an oxygen enriched combustion technique. The pyrolysis and gasification garbage incinerator comprises an oxygen preparation unit, an oxygen injection unit and an incinerator main body unit, wherein the oxygen injection unit is connected with the oxygen preparation unit and the incinerator main body unit, the oxygen injection unit comprises a booster fan, a shutoff valve and two oxygen flow control devices, and each oxygen flow control device comprises a flow meter, a regulating valve, a stop valve, a mixer and an air supply fan; the shutoff valve is connected with the flow meters; the incinerator main body unit comprises an incinerator body and a smoke purification device, and the incinerator body comprises a first combustion chamber, a second combustion chamber and a partition. According to the pyrolysis and gasification garbage incinerator, the problems of low combustion temperature and combustion efficiency, substandard pollutant discharge and the like caused by low oxygen content of air or low garbage calorific value can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preventing nitrogen increment of LF refined low-nitrogen steel

InactiveCN104988281AAvoid nudityReduce nitrogen uptakeProcess efficiency improvementSlagLow nitrogen

The invention discloses a method for preventing nitrogen increment of LF refined low-nitrogen steel. The method comprises the following steps: allowing molten steel tapped from a converter to enter a station, and carrying out argon stirring under an argon flow of 30-60Nm / l; sequentially adding fluorite, submerged arc slag, small-grain ash, calcium carbide and a deoxidizer in the LF refining process; and selecting a high-grade heavy-current heating mode of the above LF furnace. The method avoids exposure of the molten steel through controlling the argon flow amount without changing present devices or refractory, shortens the existence time of high temperature slag through controlling the heating grade and the current value, avoids slag agglomeration induced long-time heating and stirring through controlling the charging sequence, and reduces the nitrogen absorption of the molten steel in a low oxygen state through controlling the deoxidation moment in order to reduce the nitrogen increment of the molten steel in the refining process. The method has the characteristics of production of low-carbon steel through fully utilizing present conditions of refining without vacuum treatment, easy realization and low production cost.

Owner:HEBEI IRON AND STEEL

Output steel deoxidizing process under semisteel catching carbon practice condition

ActiveCN104988272AHigh water oxygen activityGuaranteed performanceManufacturing convertersNitrogenMaterial consumption

The invention belongs to the technical field of metallurgy, and particularly relates to an output steel deoxidizing process under the semisteel catching carbon practice condition. The process includes the steps that when the percentage mass content of carbon in molten steel at the end point of a converter is larger than or equal to 0.10% and smaller than 0.20%, carburant is added for preliminary deoxidization when steel is output by one third; a deoxidizing agent is added for thorough deoxidization on a blowing-argon-behind-converter platform after steel is completely output; when the percentage mass content of carbon in molten steel at the end point of the converter is larger than or equal to 0.20%, the output steel is not deoxidized, the deoxidizing agent is directly added for oxygen determination on the blowing-argon-behind-converter platform, the deoxidizing agent is added according to the oxygen determination value, and argon is blown to ladle bottoms when and after steel is output. By means of the process, deoxidization material consumption can be lowered, production cost can be reduced, and meanwhile the nitrogen increase volume in the steel output process can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

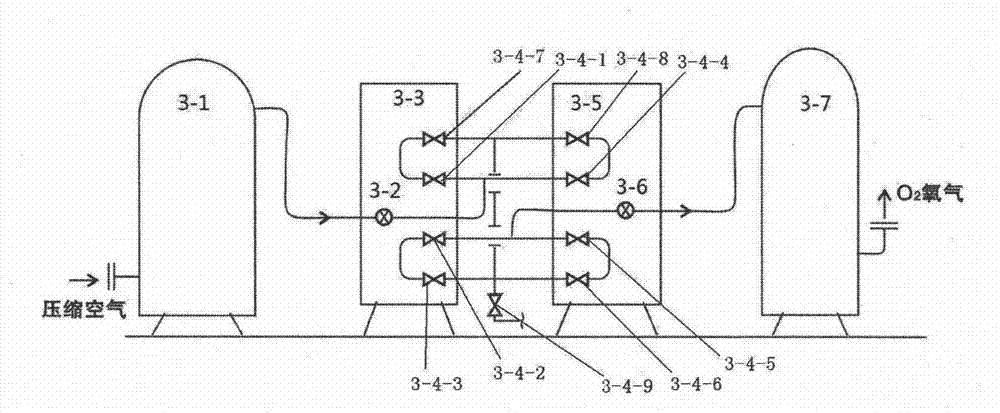

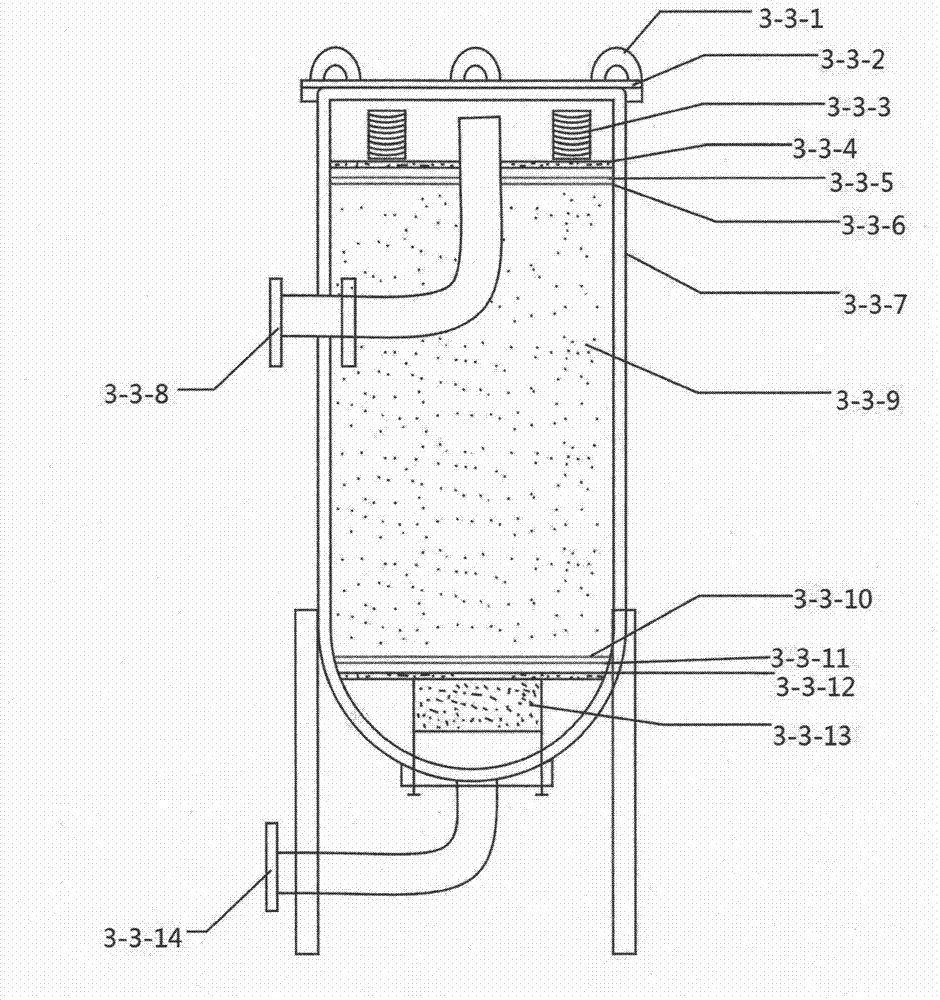

Adjustable oxygenation energy-saving combustion-supporting system

InactiveCN102788362ASignificant energy savingProcess environmental protectionChemical industryIndirect carbon-dioxide mitigationEnvironmental resistanceHabit

The invention relates to an adjustable oxygenation energy-saving combustion-supporting system. The adjustable oxygenation energy-saving combustion-supporting system is characterized by comprising an air compression unit, an air purification unit, an oxygen-nitrogen separation unit, an oxygenation adjusting mixer unit and an oxygenation applying nozzle unit. The invention provides an adjustable oxygenation energy-saving combustion-supporting system to change the manner of combustion support of air and save the fuel through a stable system in lower cost under the condition that the yield and the quality of the product are unchanged and even improved; meanwhile, the requirements of environmental protection are better met. According to the primary condition of energy conservation measure, the furnace age, the operation habit and the management condition of the primary furnace, after the adjustable oxygenation energy-saving combustion-supporting system is adopted, the energy-saving effects of various industrial furnaces are as follows: 5%-20% for various fuel coal industrial furnaces, 6%-30% for various fuel oil industrial furnaces, and3%-18% for various fuel coal industrial furnaces.

Owner:SHANGHAI SHENGLIANG ENERGY SAVING TECH DEV

Method for manufacturing wrapped core wire composite low azotic acierated powder and dearated alloy powder, and method of application

InactiveCN1759948AAvoid the problem of exposed nitrogen absorptionReduce the amount of nitrogenAlloyMolten steel

A low-nitrogen carburant powder-deoxidizing alloy powder cored wire for recarburizing and deoxidizing molten steel is composed of a core prepared from the mixture of low-nitrogen carburant powder and deoxidizing alloy powder, and a shell made of high-quality steel sheet (or band). It is applied by inserting it through molten slag layer into molten steel.

Owner:董杰吉 +5

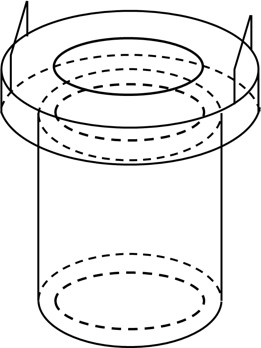

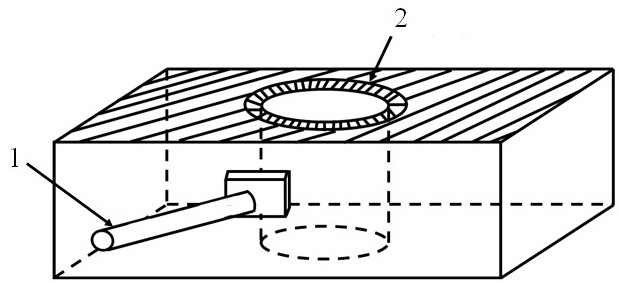

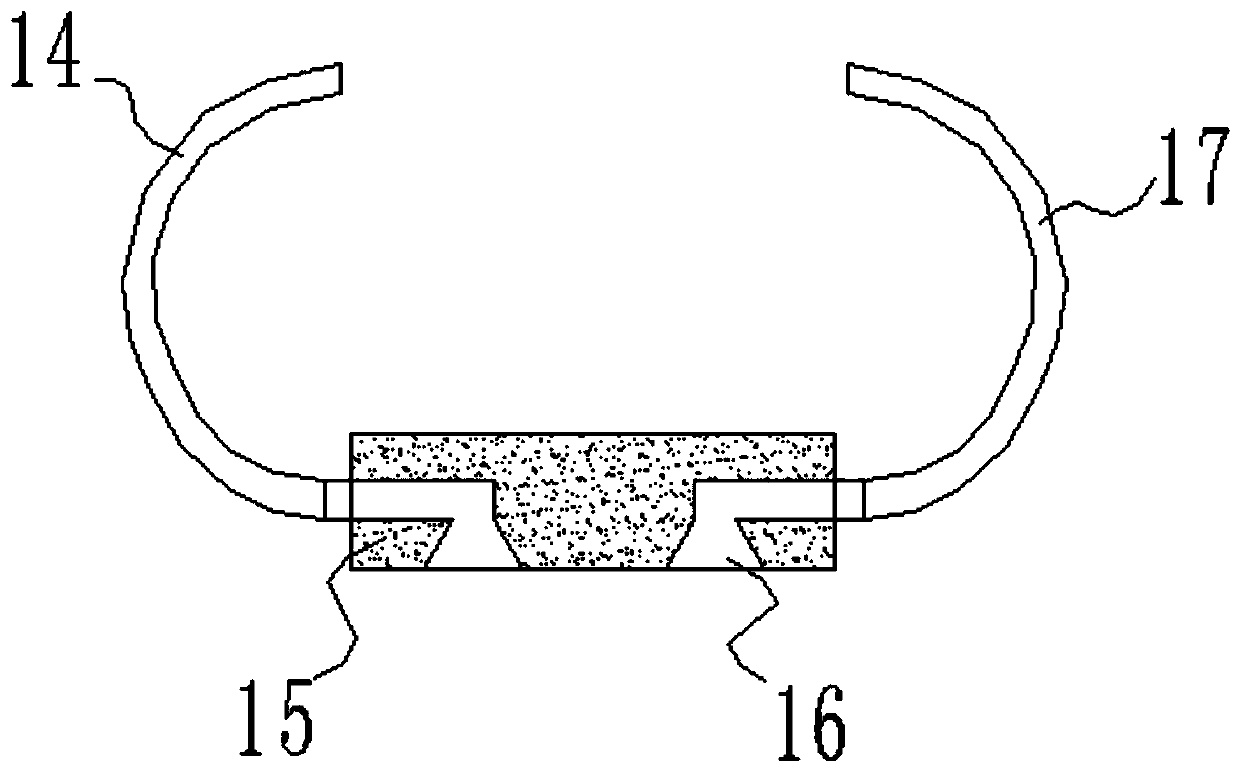

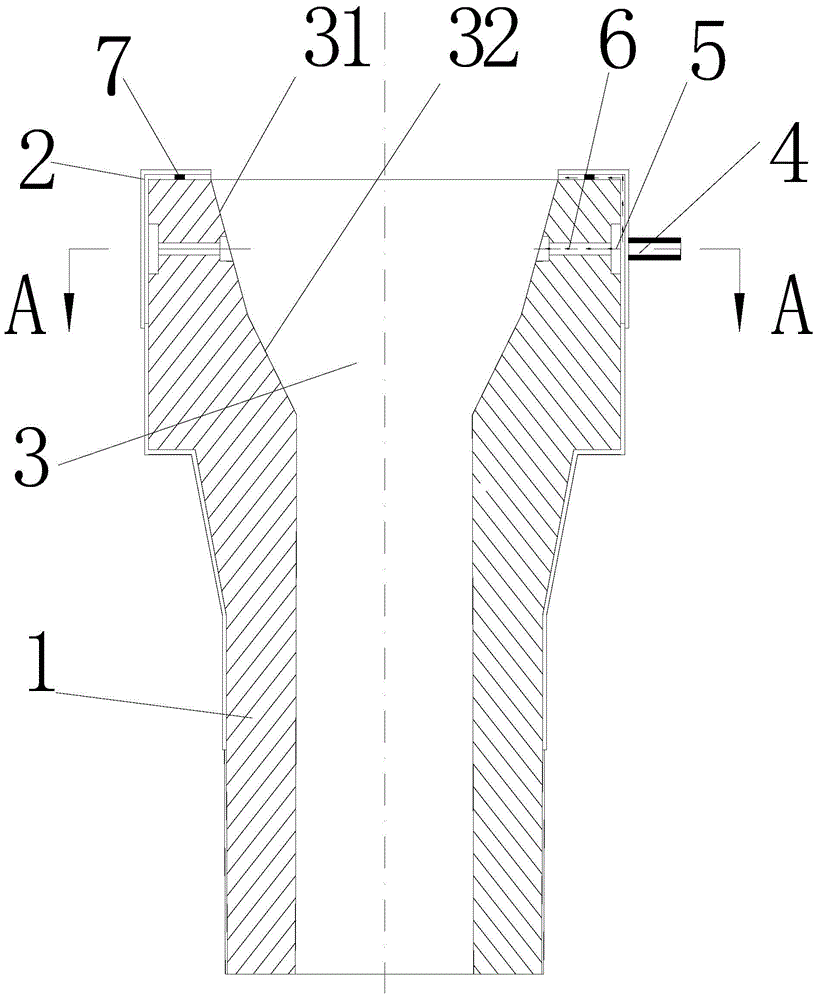

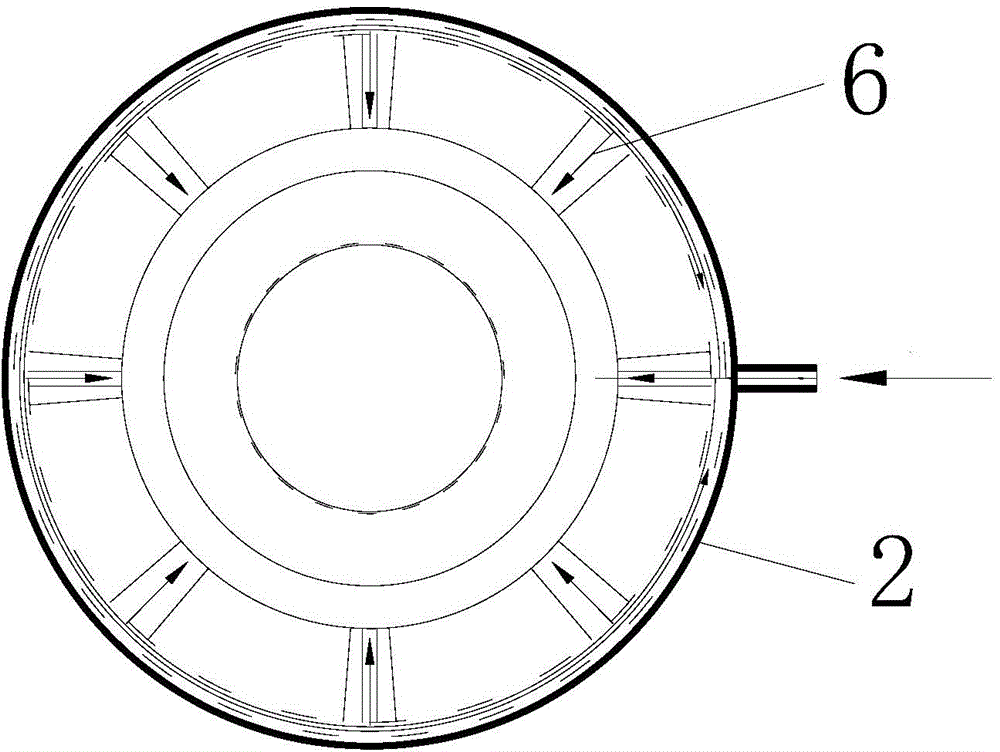

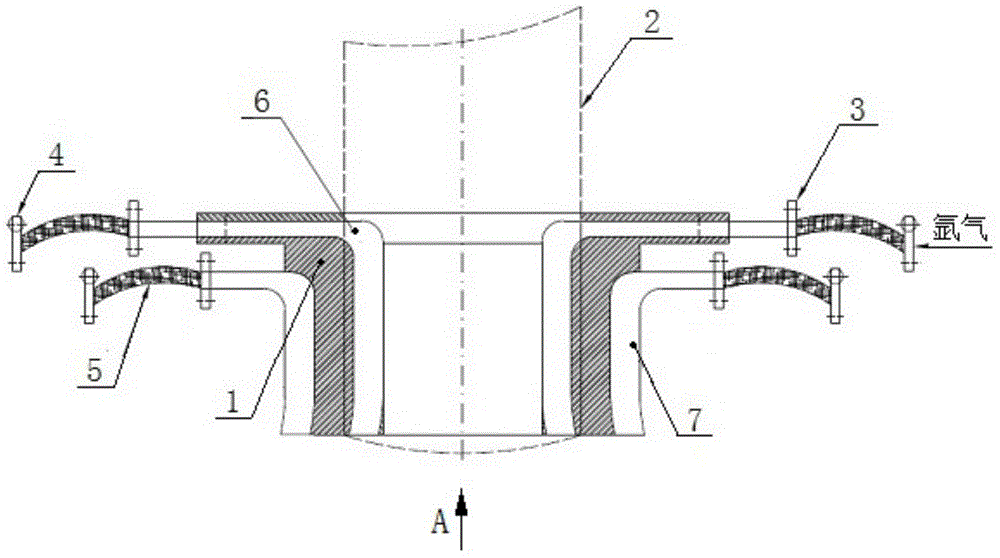

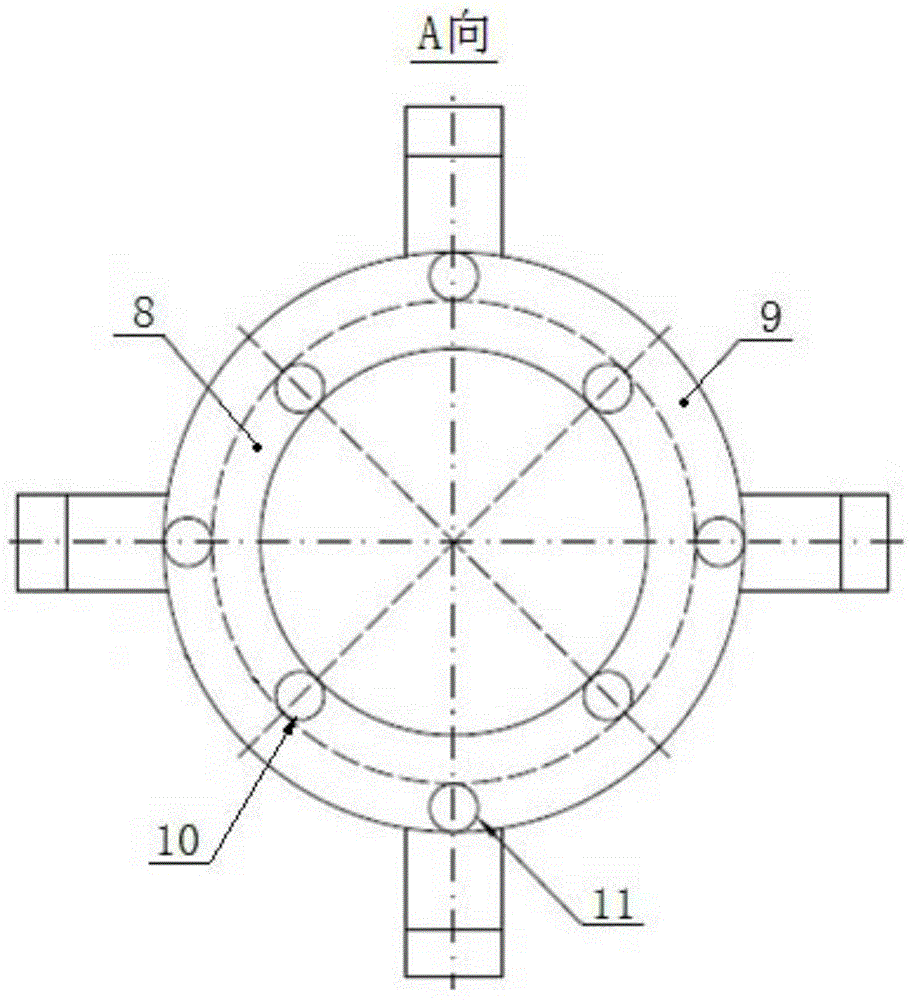

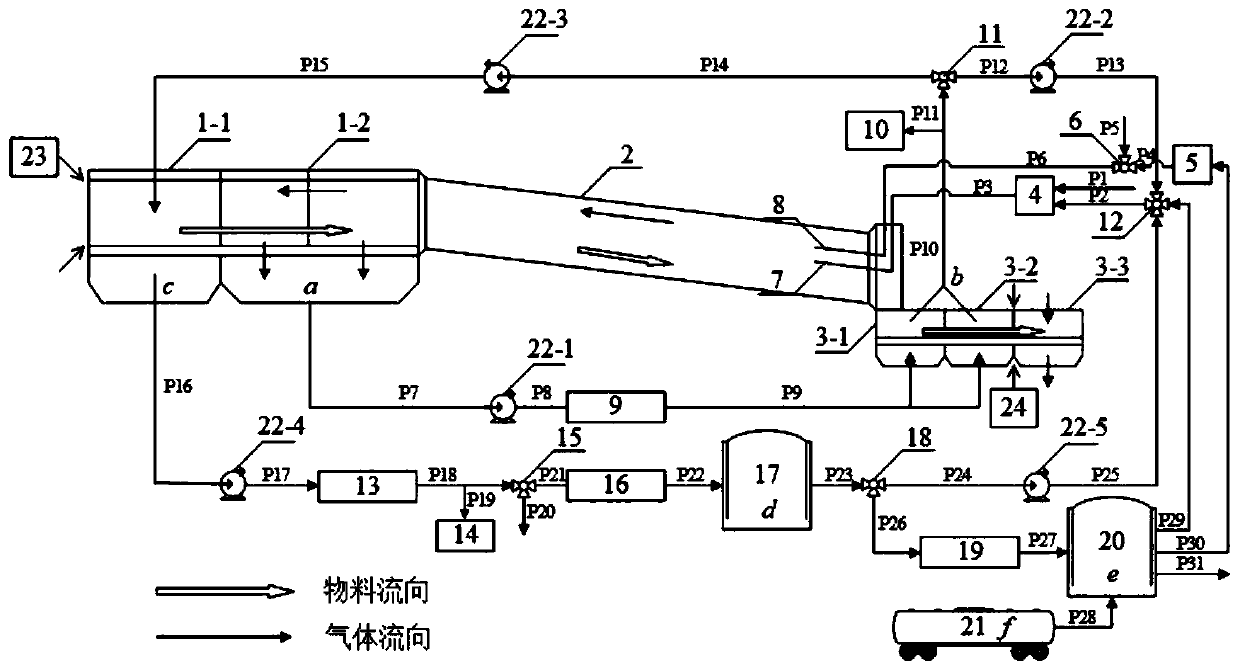

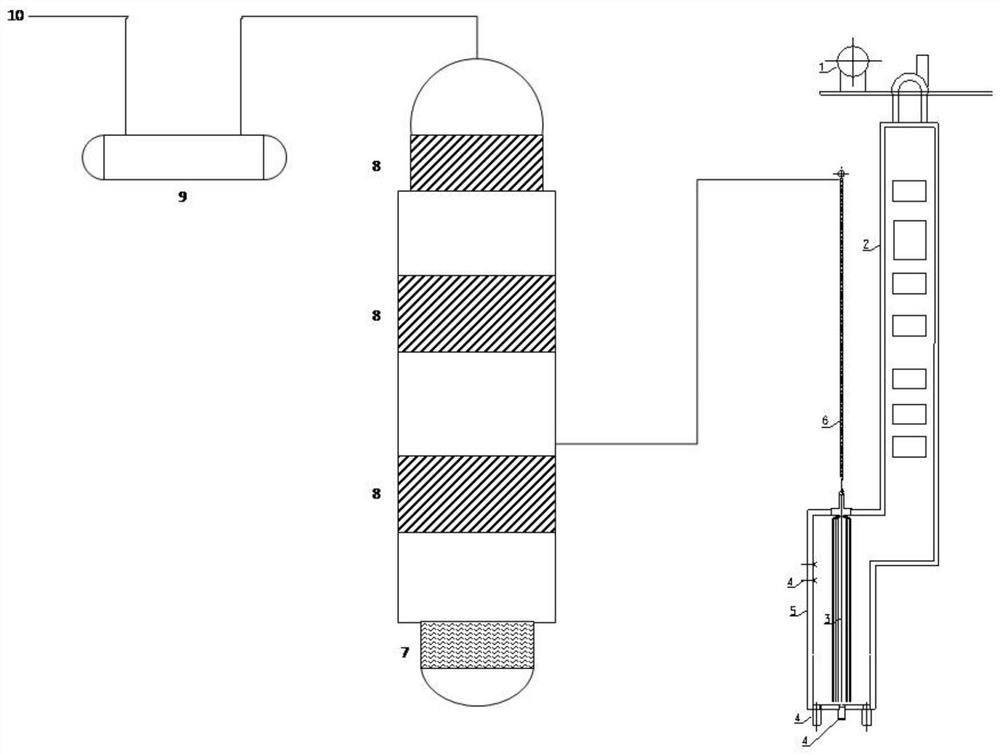

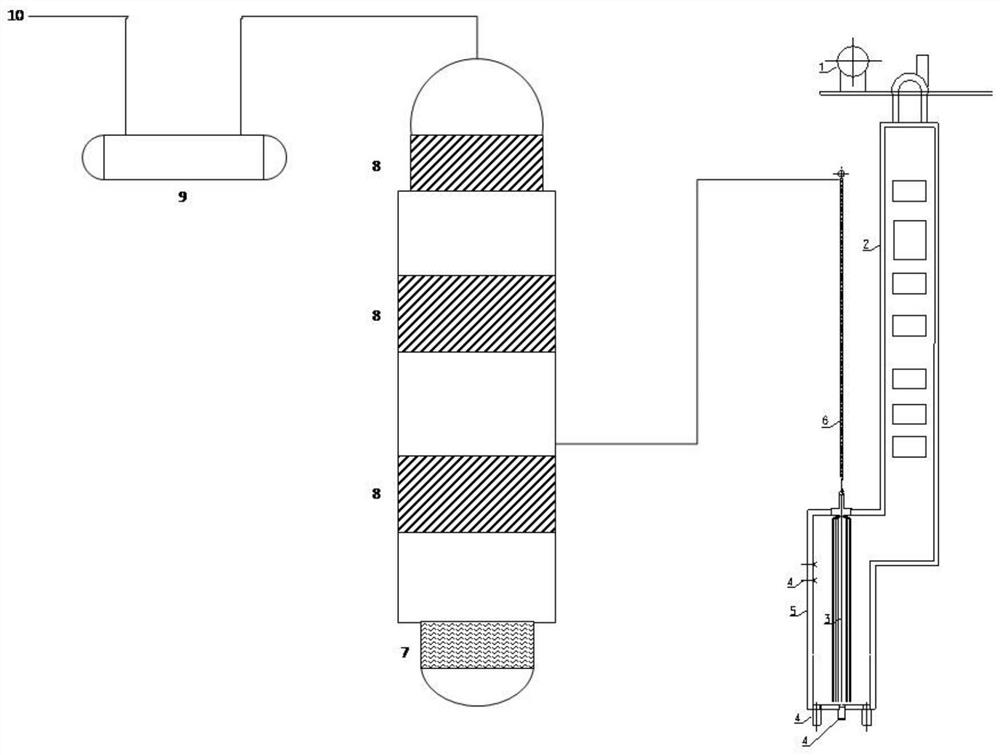

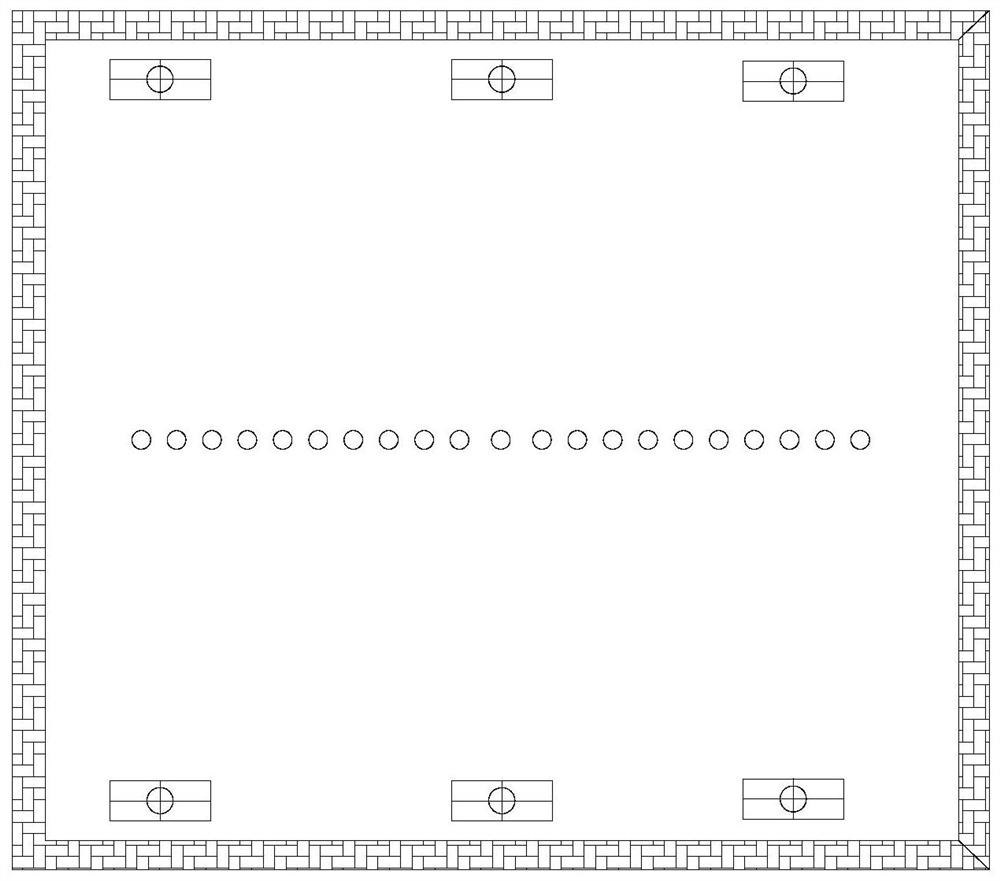

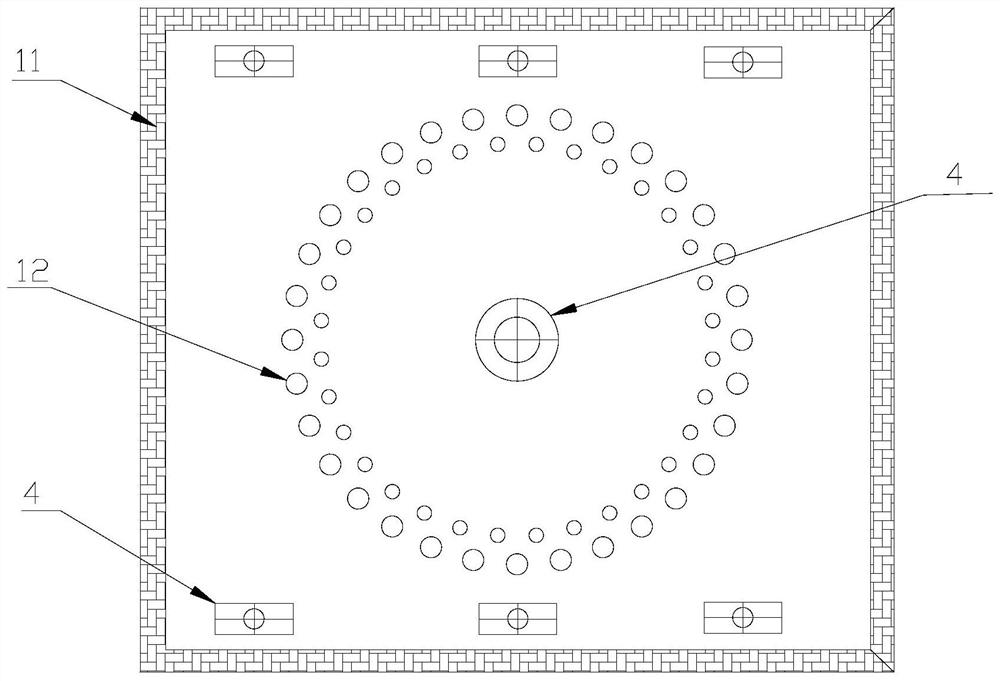

Long nozzle and continuous casting method

InactiveCN104057078AReduce the amount of nitrogenQuality improvementMelt-holding vesselsNitrogenEngineering

The invention discloses a long nozzle and a continuous casting method. The long nozzle comprises a durable material (1) and a steel sleeve (2) arranged outside the durable material in a sleeving way, wherein a hollow part (3) is arranged in the durable material; the durable material is sequentially provided with a gas inlet (4), an annular gas chamber (5) and a vent groove (6), which are communicated with one another, in the thickness direction; the vent groove extends in the thickness direction of the durable material to be communicated with the hollow part; a plurality of gas gaps are formed between the upper surface of the durable material and the steel sleeve, and are communicated with the top of the hollow part and the gas inlet respectively. According to the long nozzle, a double-sealing mode is adopted, a lower nozzle of a large ladle is primarily sealed through the gas inlet, the annular gas chamber and the vent groove by gas, and meanwhile, the combination part of the long nozzle and the lower nozzle of the large ladle can be secondarily sealed through the gas gaps formed by a plurality of bumps which are distributed on the upper surface of the durable material at intervals by the gas, so that double sealing effects are achieved, the sealing performance is high, the nitrogen increase of molten steel from the large ladle to a medium ladle can be effectively reduced, and the nitrogen increase of the molten steel in a continuous casting process can be controlled within 3ppm.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

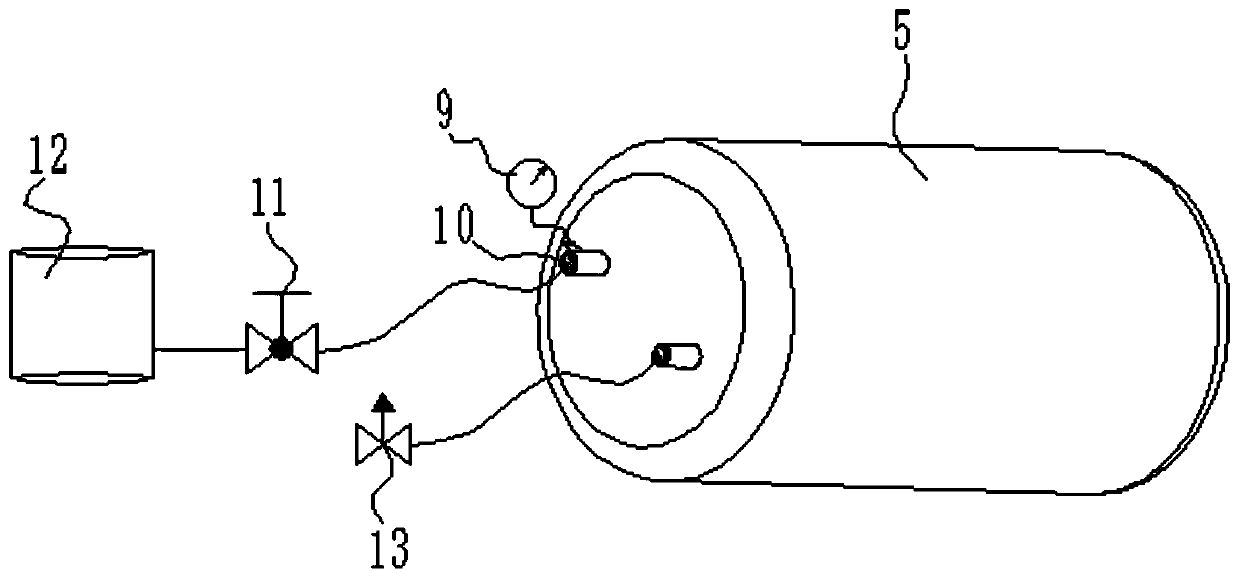

Liquid steel nitrogen increasing device and method for controlling steel tapping procedures

InactiveCN104831017AAvoid secondary oxidationControlling the Effects of Nitrogen AdditionManufacturing convertersNitrogenLiquid steel

The invention discloses a liquid steel nitrogen adding device for controlling steel tapping procedures. The liquid steel nitrogen adding device comprises a cylindrical argon plug, electric stop valves and electric flow regulating valves. The cylindrical argon plug sleeves a steel tapping opening, two argon plug rings are uniformly distributed at the lower end of the cylindrical argon plug, and a plurality of argon holes are formed in the two argon plug rings in a staggered manner; a plurality of argon pipelines which are communicated with the argon holes are uniformly arranged in the cylindrical argon plug in a staggered manner; argon metal hoses are externally connected with the argon pipelines and are connected with argon sources, the electric stop valves and the electric flow regulating valves respectively. A method for controlling the steel tapping procedures includes enabling pipeline argon to flow before the steel tapping procedures are carried out; enabling argon in the inner ring and the outer ring to flow at first to form two cone argon layers when the steel tapping procedures are carried out; adjusting the electric flow regulating valves to control the flow of the argon; shutting the electric stop valves when the steel tapping procedures are terminated. The liquid steel nitrogen adding device and the method have the advantages that liquid steel and steel drop are enclosed by two argon cones, accordingly, liquid steel nitrogen adding effects for controlling the steel tapping procedures can be realized, the liquid steel nitrogen adding device is simple in structure and low in manufacturing cost, the method is easy to implement, and obvious effects can be realized.

Owner:SHANDONG IRON & STEEL CO LTD

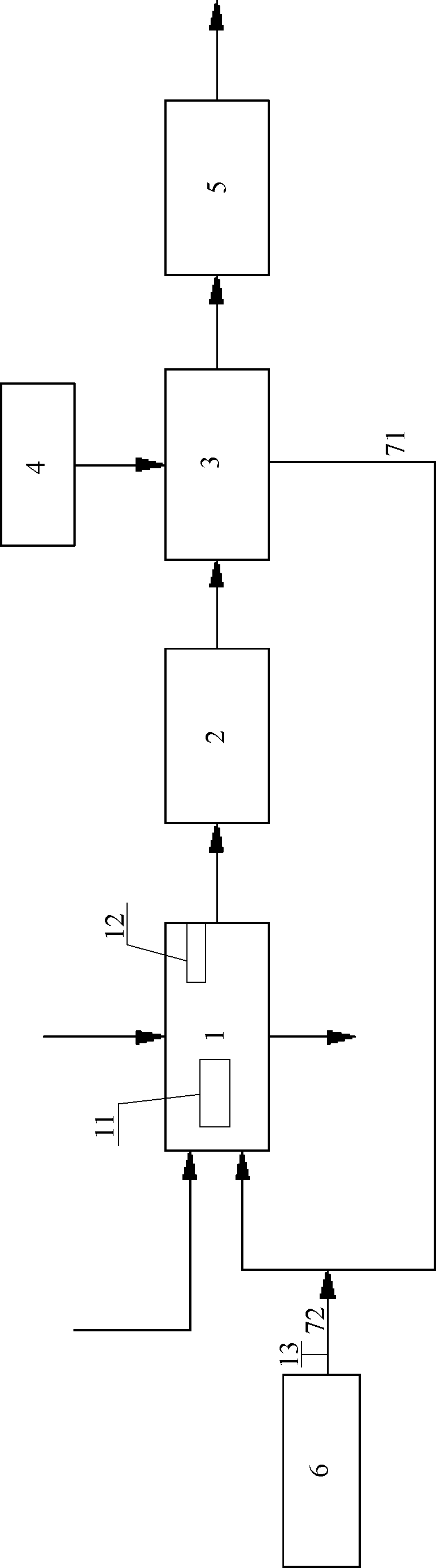

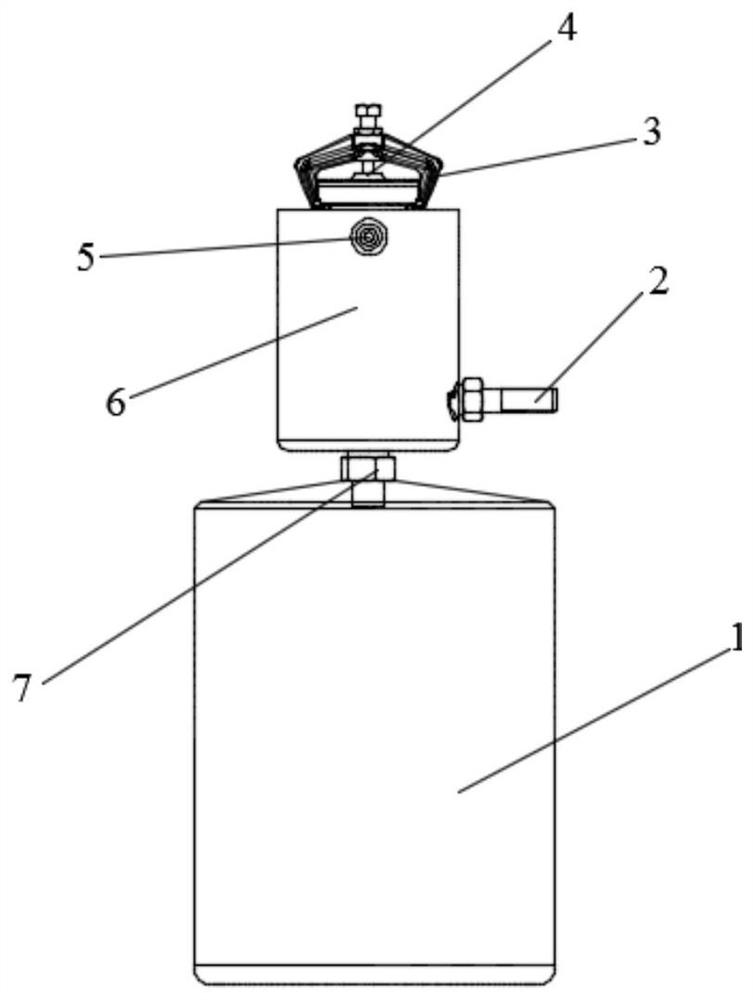

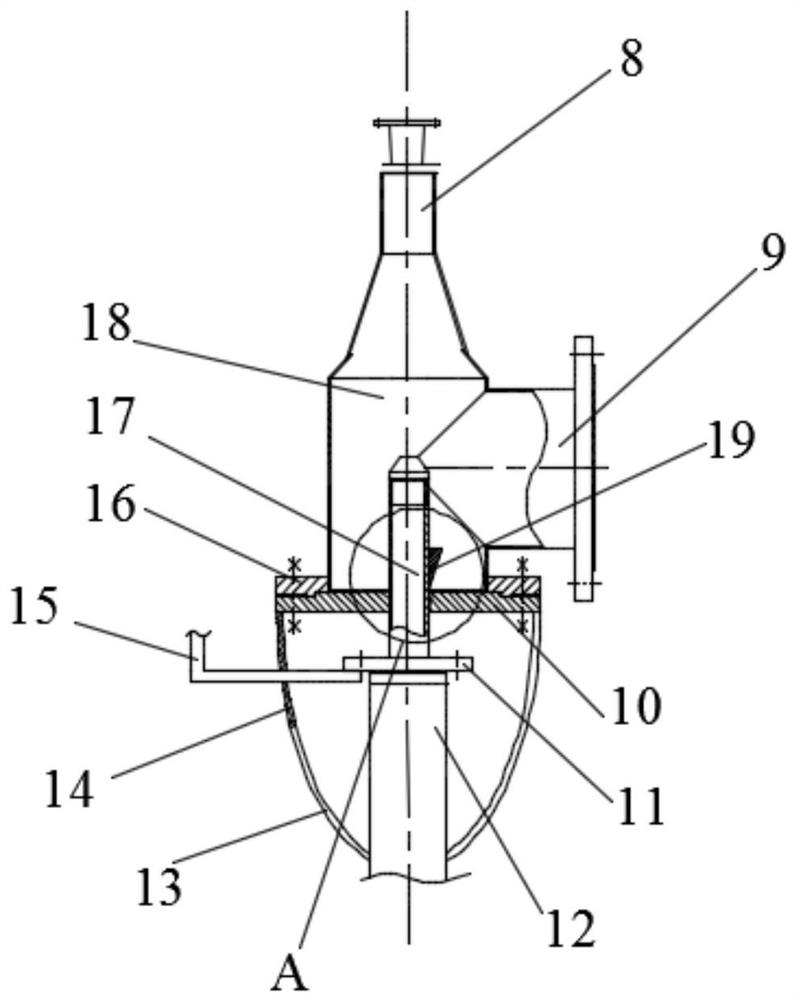

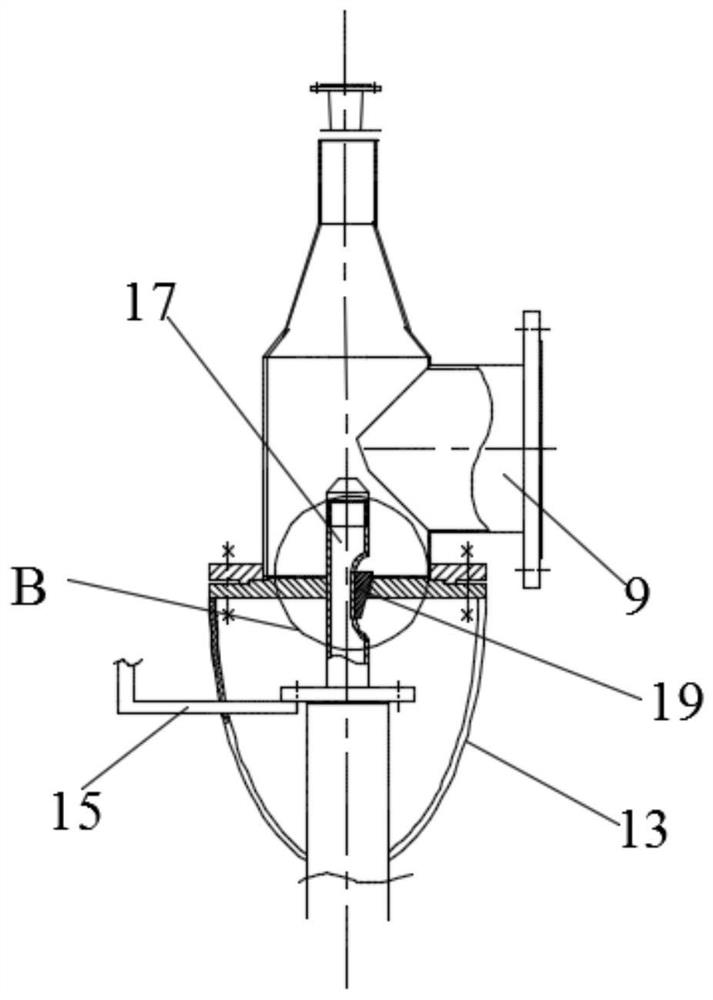

Garbage incineration device in oxygen-enriched atmosphere and using method thereof

InactiveCN108253428ADecompose thoroughlyBurn fullyEmission preventionIndirect carbon-dioxide mitigationFlue gasLower grade

The invention relates to the field of methods or equipment specially suitable for incineration of waste or low-grade fuel, in particular to a garbage incineration device in an oxygen-enriched atmosphere and a using method thereof. The garbage incineration device in the oxygen-enriched atmosphere comprises an incinerator (1), and is characterized in that the garbage incineration device further comprises a dust remover (2), a heat exchange device (3), a combustion-supporting fan (4), a purifier (5) and an oxygen generator (6), a flue gas outlet of the incinerator (1) is connected with an inlet of a flue gas pipeline of the heat exchange device (3) through the dust remover (2), an outlet of the flue gas pipeline of the heat exchange device (3) is connected with the purifier (5), and an oxygenoutlet of the oxygen generator (6) is connected with a flue gas delivering pipe (71) through an oxygen delivering pipe (72). The using method of the garbage incineration device in the oxygen-enrichedatmosphere is characterized in that the method is implemented according to the following steps of a, material preparing, b, incineration, c, heat exchanging, and d, flue gas exhausting sequentially.According to the garbage incineration device in the oxygen-enriched atmosphere and the using method thereof, full combustion is achieved, complete degradation is achieved, and adaptability is high.

Owner:BAOSTEEL ENG & TECH GRP

Saving type high-pressure water mist fire extinguisher

The invention discloses a saving type high-pressure water mist fire extinguisher. A water-gas mixing control mechanism and a control mechanism are arranged, the water-gas mixing control mechanism enables high-pressure water supplied by a high-pressure water supply pipe to be mixed with nitrogen supplied by a high-pressure nitrogen tank, the control mechanism can adjust and control the proportion of high-pressure water and high-pressure nitrogen in the water-gas mixing control mechanism, so that when the aerial fog is sprayed, the proportion of water and nitrogen in the aerial fog sprayed by an aerial fog spraying nozzle is changed, therefore, the fire extinguishing capacity and effect are improved through the change of the proportion, and meanwhile nitrogen can be saved. The proportion of water to nitrogen in aerial fog sprayed by the aerial fog spraying nozzle is variable, contact between air and fire can be effectively isolated by adding the nitrogen, the temperature can be effectively reduced by utilizing the water fog, the fire extinguishing capacity and effect can be effectively improved, meanwhile, different control and operation can be achieved according to different fire extinguishing stages, and the purpose of saving nitrogen is achieved, and the fire extinguishing effect is improved.

Owner:JILIN JIANZHU UNIVERSITY

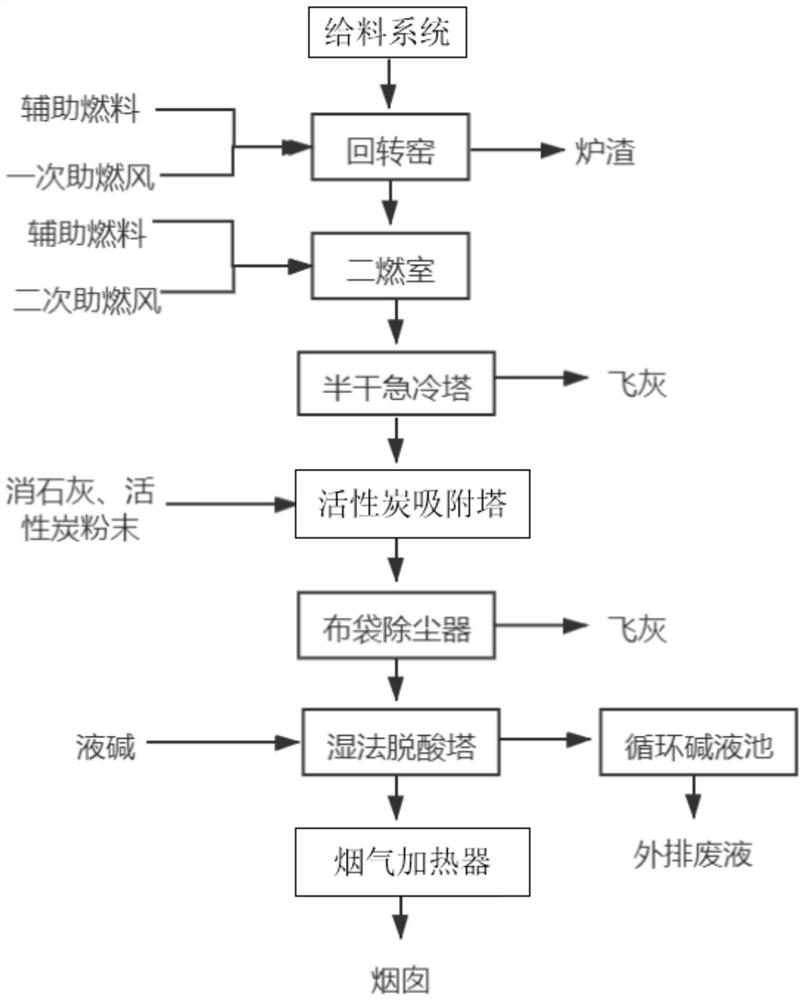

Hazardous waste incineration process and system

PendingCN112212335AReduce productionLow investment costAir/fuel supply for combustionIncinerator apparatusCombustionFlue gas

The invention discloses a hazardous waste incineration process and system. The hazardous waste incineration process comprises the following steps that S1, compatibility is conducted, specifically, hazardous waste is mixed and compatible and conveyed into a first incineration area; S2, incineration is conducted, specifically, the mixed materials obtained after compatibility are subjected to a primary combustion reaction in a first incineration area, and primary flue gas is obtained; the primary flue gas is conveyed into a second incineration area to be subjected to a secondary combustion reaction, and secondary flue gas is obtained; S3, flue gas treatment is carried out, specifically, the secondary flue gas is cooled and purified and then discharged; in the primary combustion reaction process, used combustion-supporting gas I contains 45%-55% of oxygen; and in the secondary combustion reaction process, used combustion-supporting gas II contains 75-85% of oxygen. According to the processand system, the investment and operation cost is low, and the treatment effect is good.

Owner:江门市崖门新财富环保工业有限公司

Tapping Deoxidation Process of Semi-steel under High-draw Carbon Condition

ActiveCN104988272BHigh water oxygen activityGuaranteed performanceManufacturing convertersMaterial consumptionNitrogen

The invention belongs to the technical field of metallurgy, and particularly relates to an output steel deoxidizing process under the semisteel catching carbon practice condition. The process includes the steps that when the percentage mass content of carbon in molten steel at the end point of a converter is larger than or equal to 0.10% and smaller than 0.20%, carburant is added for preliminary deoxidization when steel is output by one third; a deoxidizing agent is added for thorough deoxidization on a blowing-argon-behind-converter platform after steel is completely output; when the percentage mass content of carbon in molten steel at the end point of the converter is larger than or equal to 0.20%, the output steel is not deoxidized, the deoxidizing agent is directly added for oxygen determination on the blowing-argon-behind-converter platform, the deoxidizing agent is added according to the oxygen determination value, and argon is blown to ladle bottoms when and after steel is output. By means of the process, deoxidization material consumption can be lowered, production cost can be reduced, and meanwhile the nitrogen increase volume in the steel output process can be reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

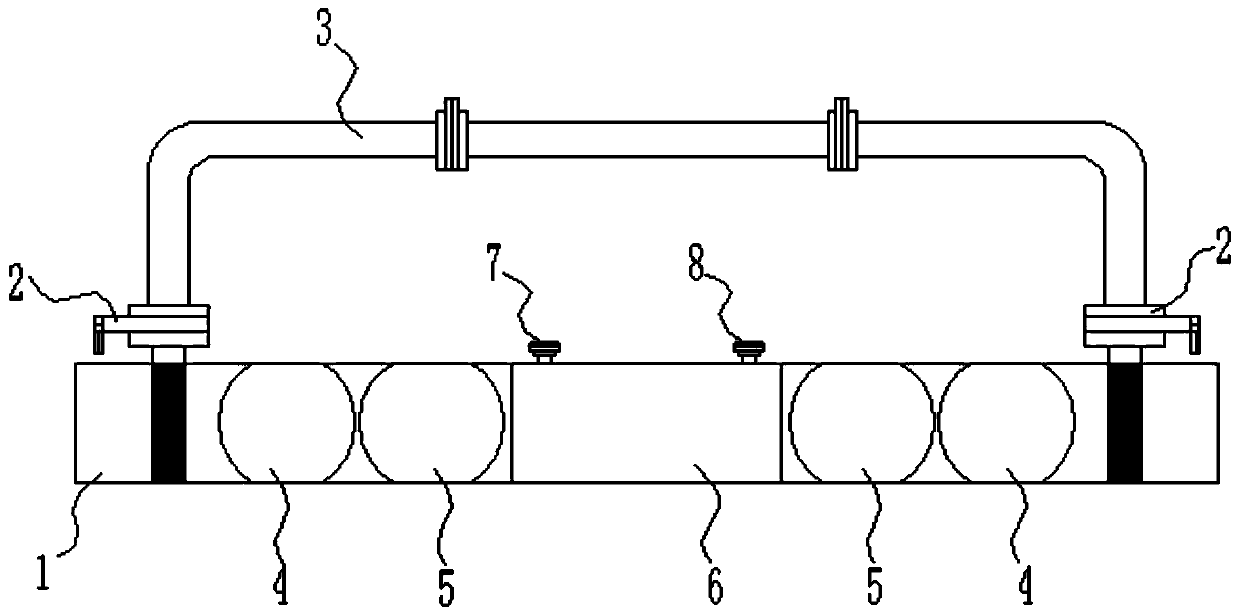

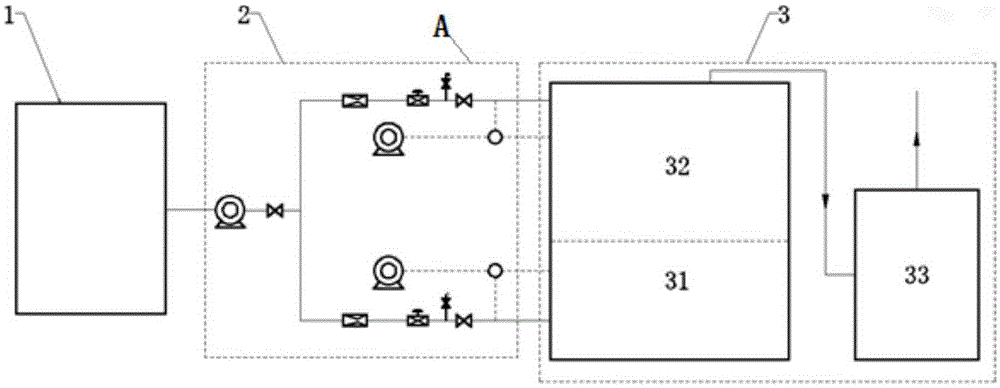

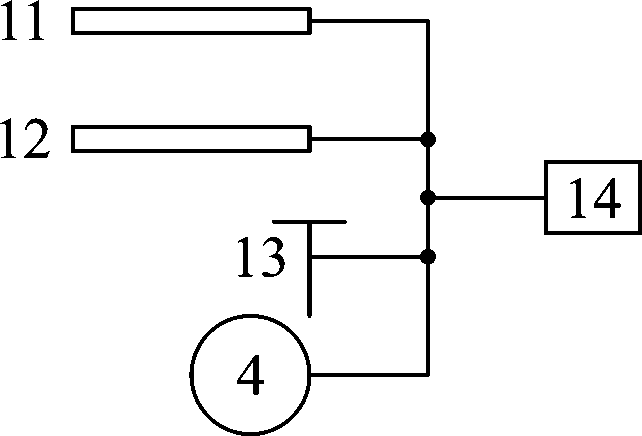

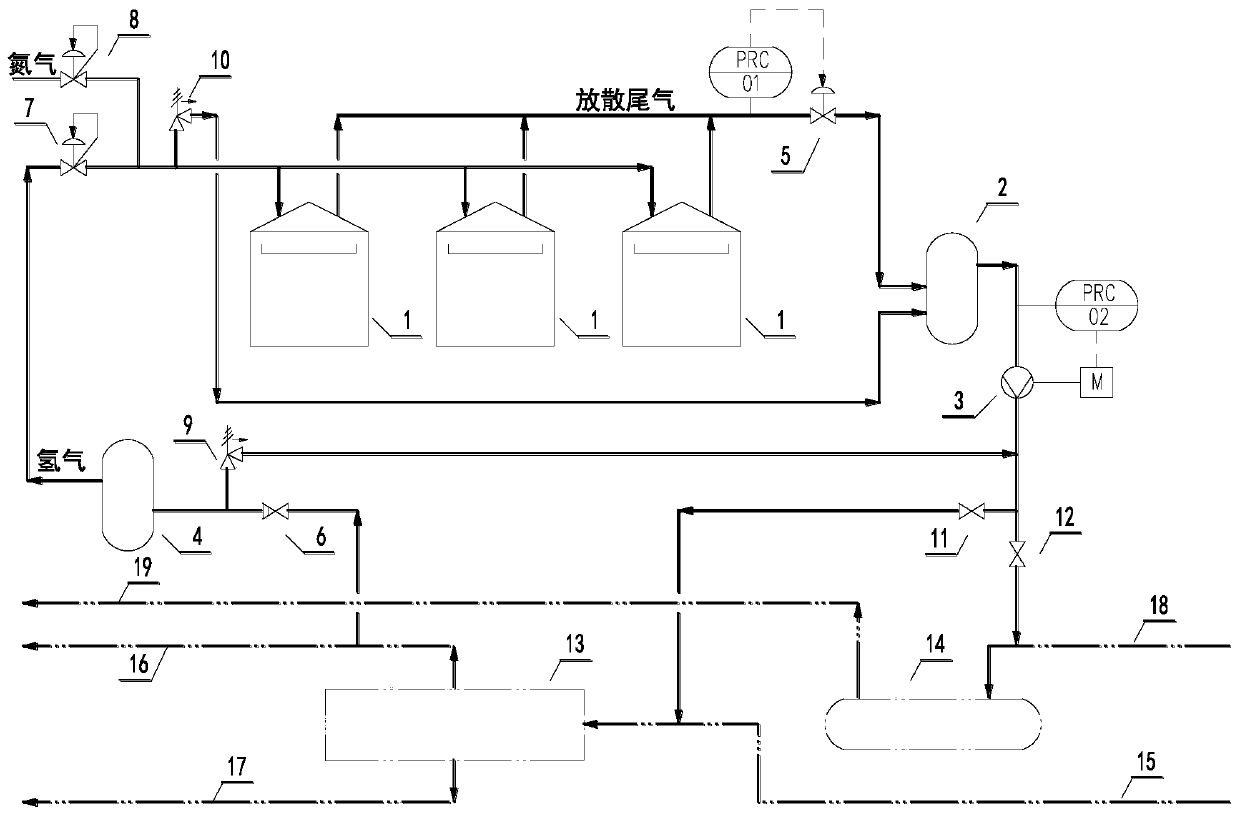

Oil storage exhaust gas sealed recovering process by using self-produced surplus hydrogen

PendingCN109812703AReduce the impact of gas qualityReduce the amount of nitrogenLarge containersPipeline systemsHydrogenNitrogen

The invention relates to an oil storage exhaust gas sealed recovering process by using self-produced surplus hydrogen. An oil storage exhaust gas sealed recovering device comprises a gas storing and releasing buffering tank, an induced fan, a hydrogen buffering tank, a pressure adjustment valve, a pressure relief valve, a self-support hydrogen adjustment valve, a self-support nitrogen adjustment valve, a first safety valve, a second safety valve, a first valve, a second valve, a pressure recording control instrument PRC01 and a pressure recording control instrument PRC02. The oil storage exhaust gas sealed recovering device has the beneficial effects that the surplus hydrogen produced by a PSA variable-pressure adsorption hydrogen producing unit is used as the sealed gas source of the oilstorage gas releasing system, the released gas is recovered and conveyed to a raw material coal gas pipeline of the PSA variable-pressure adsorption hydrogen producing unit under the controllable state, the problem of the direct drainage of the released gas of an oil storage can be solved, the environmental pollution is reduced, the cost is low, and the energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for reducing increased nitrogen amount of high-strength steel in converter ladle

InactiveCN109055648AReduce usageReduce high nitrogen contentManufacturing convertersGas emission reductionAlloyMolten steel

The invention discloses a method for reducing an increased nitrogen amount of high-strength steel in a converter ladle. The method comprises the steps of: controlling the acid-soluble aluminum of themolten steel in the ladle to 50-200 ppm; controlling the temperature of the molten steel entering the ladle to be 1585+ / -10 DEG C; alloying manganese with medium carbon ferromanganese and electrolyticmanganese. The method reduces the nitrogen content of the high-strength steel product by controlling the acid molten aluminum content of the ladle, the temperature of the ladle and the use amount ofalloy used for replacing or reducing the high nitrogen content, and the quality of the steel is improved while the increased nitrogen amount of the molten steel in the ladle of the converter process is suppressed. The method can effectively reduce the increased nitrogen amount of the molten steel in the ladle of the high-strength steel of the converter process, from the original 15+ / -3ppm to 5+ / -2ppm, thereby improving the quality and performance of the finished steel.

Owner:HANDAN IRON & STEEL GROUP +1

Ultralow-nitrogen ultralow-boron molten steel refining agent and preparing method

The invention discloses an ultralow-nitrogen ultralow-boron molten steel refining agent and a preparing method. The refining agent is composed of a component C and a component D, the component C is low-boron active lime, the component D is single one or any combination of industrial aluminum ash, bauxite or calcium slag, the refining agent is alkalinityR:3.0-5.0(CaO / SiO2), N is smaller than or equal to 0.02%, and B is smaller than or equal to 0.001%. The advanced premelting vacuum refining process is adopted in the molten steel refining agent, the component is uniform, checking is convenient,and mechanical and manual charging is facilitated. The refining agent is free of dust, use is safe and environment-friendly, the content of harmful elements N and B is extremely low, storage and transportation are facilitated, at the high temperature, during use, the agent is not prone to oxidation by air, the yield is high, deoxidization efficiency in the slag is high, the speed is high, and therefining agent is the most ideal high-cleanliness molten steel refining agent.

Owner:西峡县耀辉冶金材料有限公司

Method for alloying ultra-low carbon and degassed steel titanium in RH furnace

InactiveCN113528758AReduce the amount of nitrogenNitrogen increase is stableManufacturing convertersButt weldingTitanium

The invention provides a method for alloying ultra-low carbon and degassed steel titanium in an RH furnace, which comprises LD-LF-RH-CC which is carried out in sequence, and comprises the following steps: in an LD stage, reducing converter blowing carbon catch to end point nitrogen increase control; in a RH stage, conducting flaw detection is on a weld joint at the butt welding position of a vacuum chamber body and an insertion pipe steel structure through a permeation method, and the vacuum chamber and the insertion pipe steel structure are connected in an inserted mode; and carrying out titanium alloying by adopting sponge titanium alloy. According to the method of the invention, the nitrogen increasing amount of each step is strictly controlled, so that the phenomenon that the nitrogen content of part of molten steel in heat is too high due to the nitrogen contained in the alloy is restrained, the nitrogen increasing amount in the RH process is reduced to be within 2 * 10 <-6 > from the average of 6 * 10 <-6 > or above, and the nitrogen increasing amount is stably controlled to be 2 * 10 <-6 > or below; and for automobile panel IF steel, after RH treatment, the nitrogen content in the degassed (plate) high-grade steel represented by X80 is stably controlled, and the process quality control requirement is completely met.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

One based on exhaust gas recirculation o 2 -co 2 Combustion-supporting pellet production process and preparation system

ActiveCN109813129BReduce inputReduce generationCarbon compoundsRotary drum furnacesHigh concentrationNitrogen

The invention discloses a pellet production technology and preparation system based on exhaust circulation O2-CO2 combustion supporting, and belongs to the field of pellet environment-friendly efficient preparation production in the ferrous metallurgy process. The physical heat of exhaust in the production process is used for drying and preheating of pellets, and the exhaust containing high-concentration CO2 is directly mixed with or mixed with industrial pure oxygen after being purified to serve as combustion-supporting gas of fuel. According to the pellet production technology and preparation system, the waste heat of the exhaust is sufficiently utilized, and the heat utilization efficiency of the pellet preparation system is improved; approximate zero input of nitrogen of the pellet preparation system is achieved, and the generation amount of NOx in the production process is decreased from the source; and the exhaust containing the high-concentration CO2 can be used for preparing industrial grade / food grade CO2 with low cost, and a CO2 recycling and emission reduction approach is provided.

Owner:UNIV OF SCI & TECH BEIJING +1

Ultralow-nitrogen ultralow-titanium molten steel refining agent and preparation method

The invention discloses an ultralow-nitrogen ultralow-titanium molten steel refining agent and a preparation method. The refining agent is prepared from a component A and a component B, the componentA is low-titanium active lime, the component B is one or any combination of industrial aluminum ash, bauxite and calcium slag according to the ingredients and use amounts, the alkalinity R of the refining agent is 3.0-5.0(CaO / SiO2), N is smaller than or equal to 0.02%, and Ti is smaller than or equal to 0.015%. The molten steel refining agent is prepared with an advanced pre-melting vacuum refining process, the ingredients are uniform, inspection is convenient, and mechanical and manual feeding is facilitated. The ultralow-nitrogen ultralow-titanium molten steel refining agent is free of dustand safe and environmentally friendly during use, the content of harmful elements N and Ti is extremely low, storage and transportation are facilitated, the ultralow-nitrogen ultralow-titanium moltensteel refining agent is not easily oxidized by air during use at high temperature, the yield is high, the deoxidization efficiency in slag is high, the speed is high, and the ultralow-nitrogen ultralow-titanium molten steel refining agent is the most ideal high-cleanliness molten steel refining agent.

Owner:西峡县耀辉冶金材料有限公司

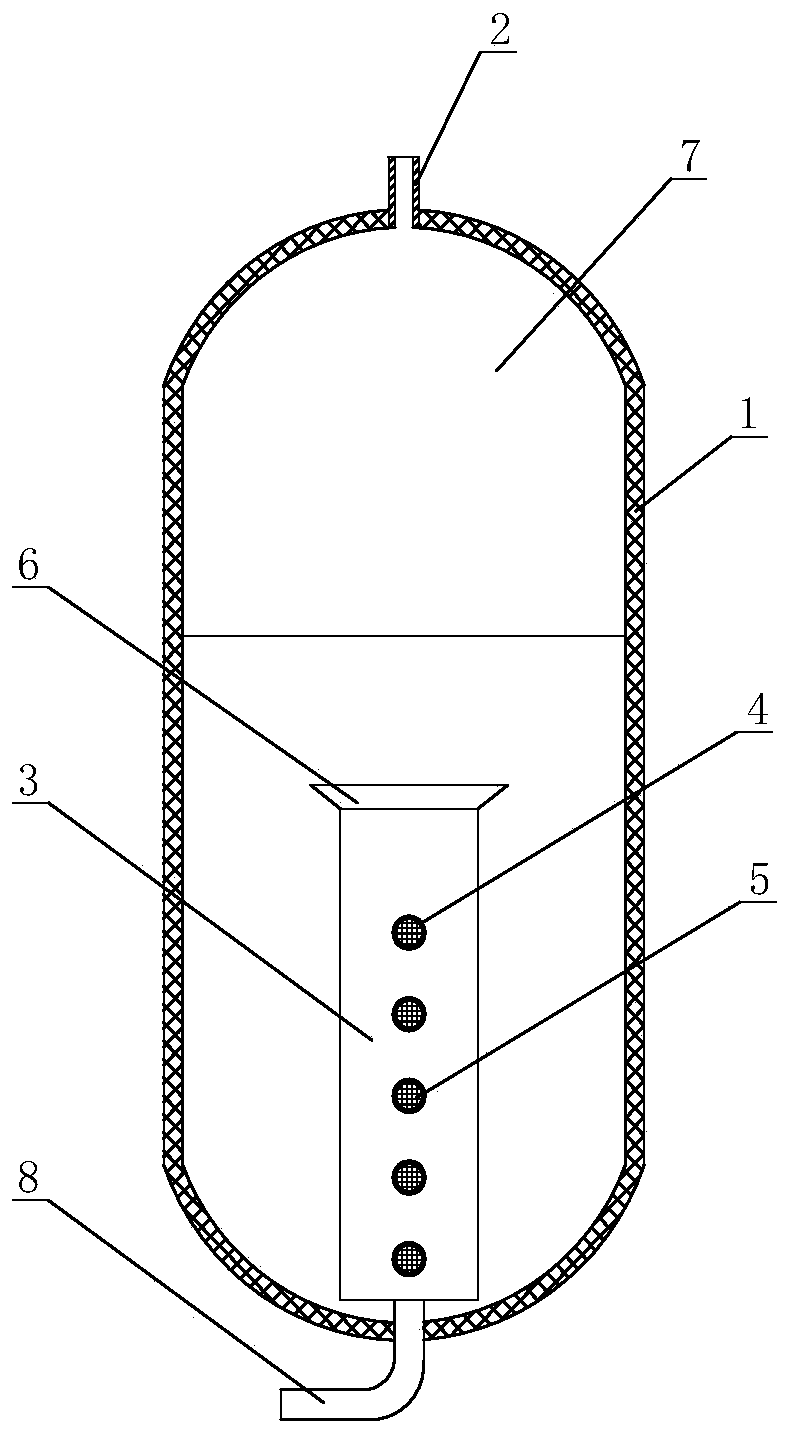

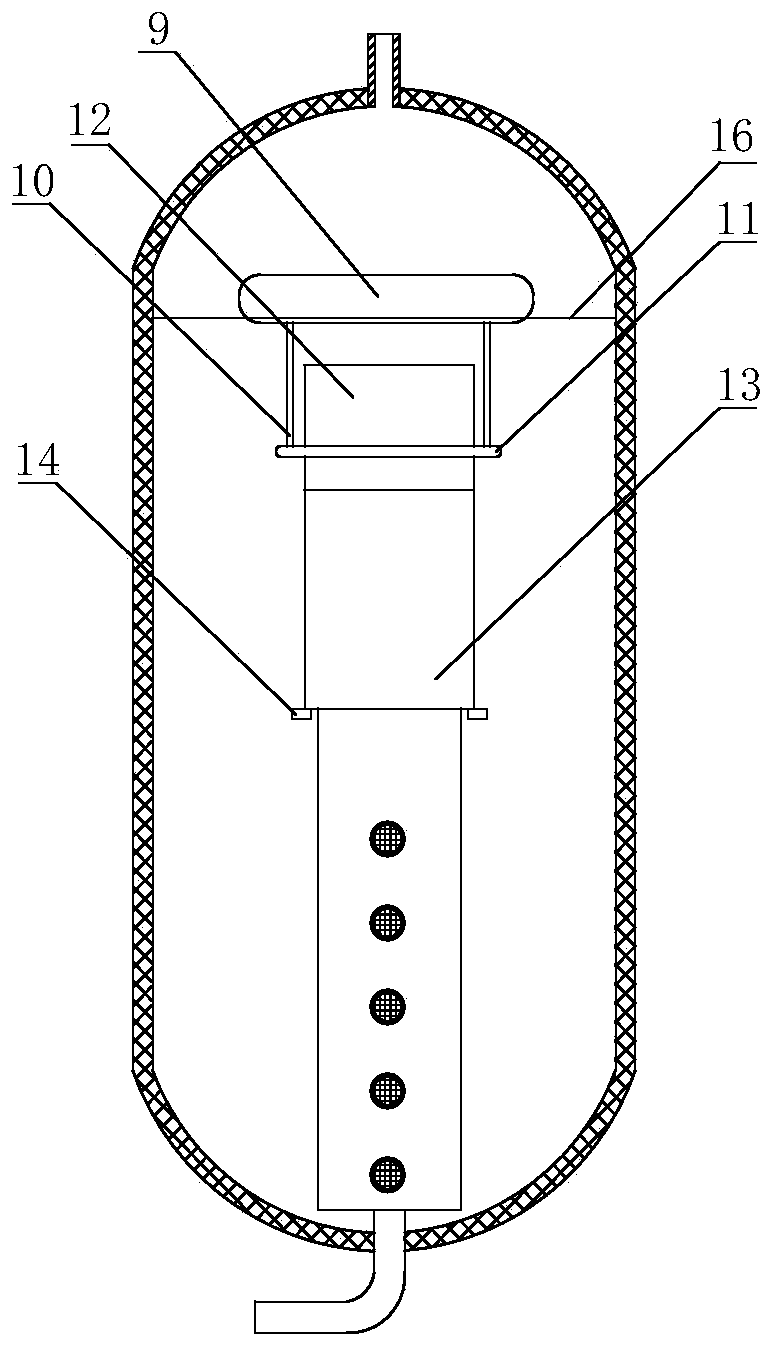

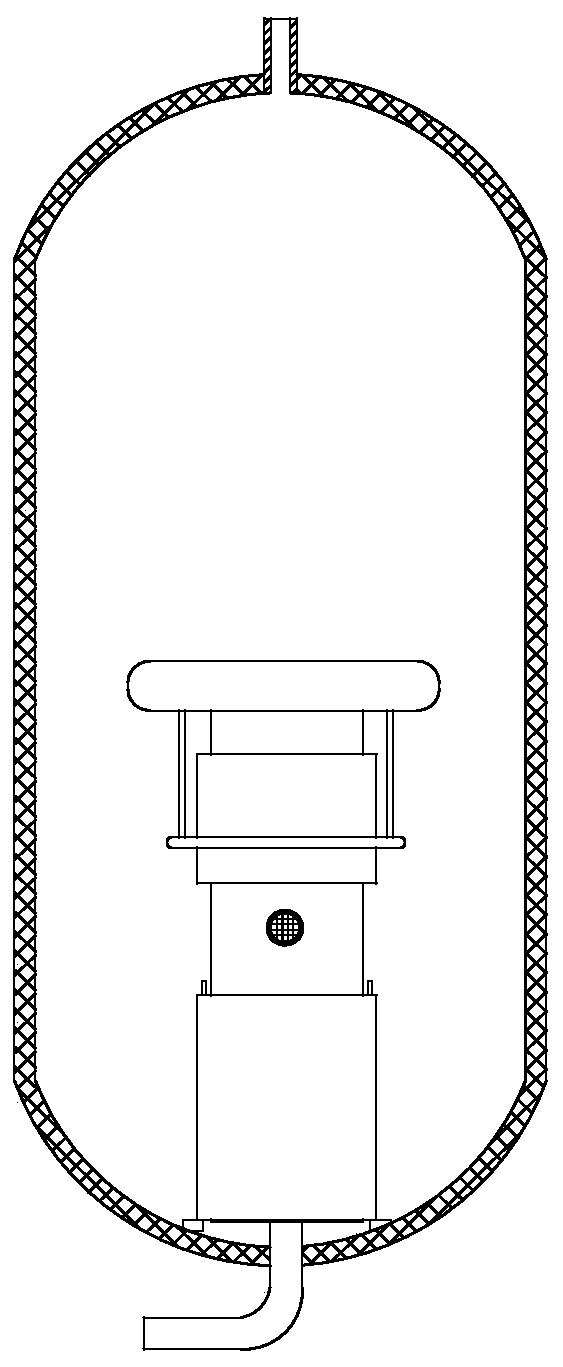

An improved safety injection box

ActiveCN109448873BSimple structureEasy to manufactureNuclear energy generationCooling arrangementCoolant flowDamper

The invention discloses an improved safety injection box, which comprises a casing, an air intake pipe is arranged on the top of the casing, a standpipe is arranged inside the casing, the top of the standpipe is an open end, and the bottom of the standpipe The end is a closed end, and the closed end of the standpipe is provided with a drain pipe, which connects the inside of the standpipe and the outside of the housing, and a plurality of through holes are opened on the side wall of the standpipe from top to bottom. The standpipe of the present invention can function as a damper, and the through hole provided on the standpipe can function as a small pipe, so the present invention does not need to set a damper and a small pipe, and self-adaptive adjustment of flow can be realized only with the standpipe The function of the safety injection box greatly simplifies the structure of the safety injection box, which is convenient for device manufacture and maintenance; the multiple through holes arranged on the standpipe from top to bottom make the coolant output from the safety injection box The flow rate decreases gradually and steadily, which significantly improves the reliability of the safety injection box operation.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Light olefin cracking equipment and cracking method

ActiveCN111019688BReduce cokingReduce processing costsThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingThermodynamicsCombustor

Owner:CHINA PETROLEUM & CHEM CORP +1

Light olefin cracking equipment and cracking method

ActiveCN111019691BReduce cokingReduce processing costsThermal non-catalytic crackingEthylene productionThermodynamicsPetroleum oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for controlling nitrogen content of niobium-containing steel type

InactiveCN108277319AReduce the amount of nitrogenLow costManufacturing convertersNiobiumArgon atmosphere

The invention discloses a method for controlling the nitrogen content of a niobium-containing steel type. The method is characterized in that argon is blown into an empty steel ladle before tapping ofa converter, so that molten steel flow and the molten steel surface in the tapping process are always in the argon atmosphere; and the molten steel is isolated from air by the argon, so that absorption of the molten steel to nitrogen in air is reduced, and the content of the nitrogen in the molten steel is effectively controlled. Compared with the prior art, the method for controlling the nitrogen content of the niobium-containing steel type has the beneficial effects that the nitrogen increasing amount of the niobium-containing steel type in the converter tapping process is greatly reduced,pressure for treating the molten steel is relieved for the subsequent refining process, the nitrogen content in the molten steel is prevented from exceeding the standard, the corner crack of a continuous casting blank is reduced, the offline corner cleaning cost of the continuous casting blank is reduced, and the heat charging rate of the continuous casting blank is improved.

Owner:ANGANG STEEL CO LTD

A kind of method for adjusting carbon by LF refining for carbon steel

ActiveCN110484683BShorten mixing timeReduce heating energy consumptionRefining (metallurgy)Molten steel

Owner:ANGANG STEEL CO LTD

Method for controlling nitrogen content in steel by semi-steel smelting

InactiveCN102230051BReduce the amount of nitrogenReduce nitrogen contentManufacturing convertersFoaming agentLow nitrogen

Owner:PANZHIHUA IRON AND STEEL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com