An improved safety injection box

A safety injection box and improved technology, applied in the direction of reducing greenhouse gases, climate sustainability, reactors, etc., can solve the problems of injection flow fluctuation, inconvenient maintenance, complex structure, etc., to simplify the structure, facilitate manufacturing and The effect of maintenance and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

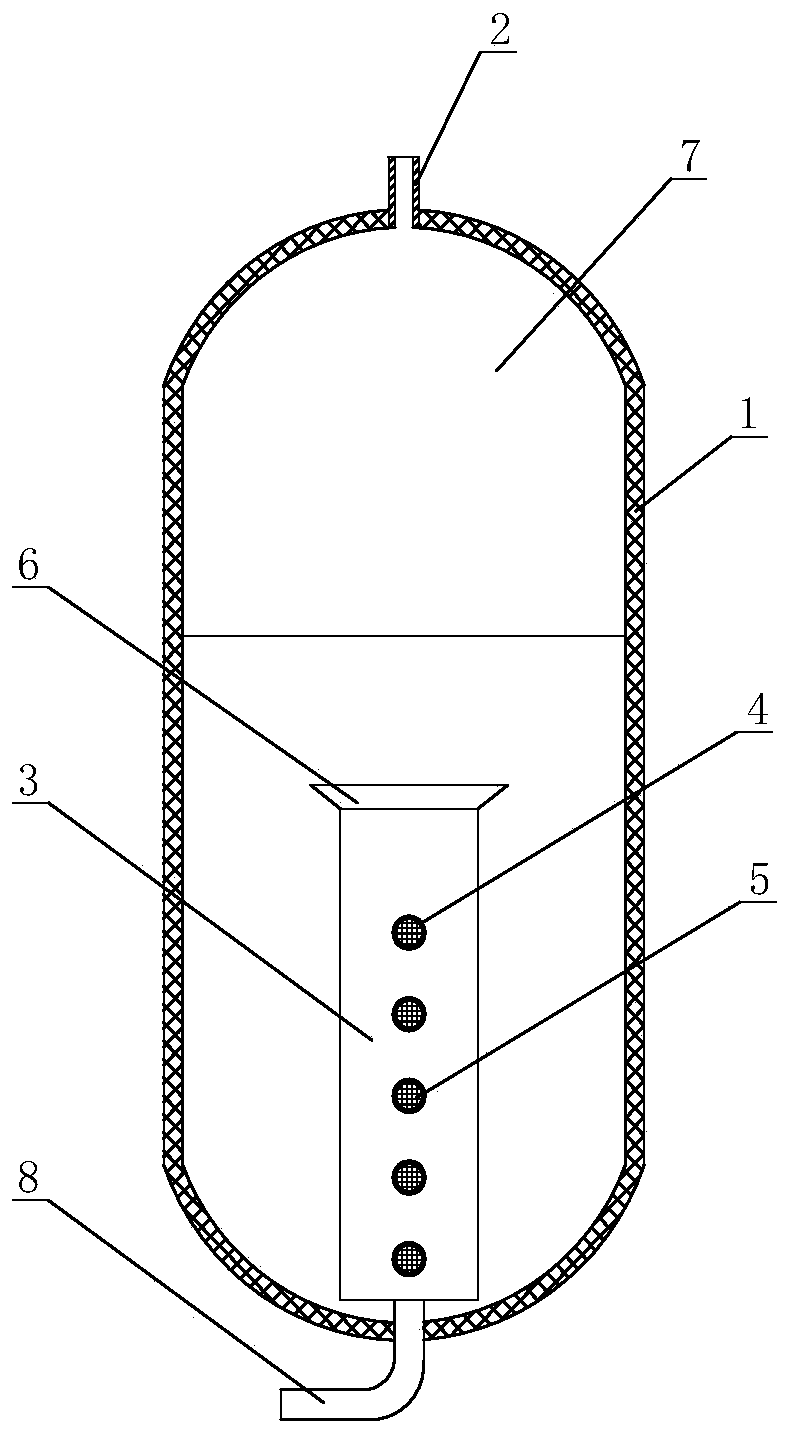

[0041] Such as figure 1 An improved safety injection box shown includes a housing 1, the top of the housing 1 is provided with an air inlet pipe 2, and the housing 1 is provided with a standpipe 3, the top of the standpipe 3 is an open end, and the bottom end of the standpipe 3 It is a closed end, and a drain pipe 8 is arranged on the closed end of the standpipe 3, and the drain pipe 8 communicates with the inside of the standpipe 3 and the outside of the housing 1, and a plurality of Through hole 4; the top of the standpipe 3 is provided with an anti-vortex device 6, and the diameter of the anti-vortex device 6 gradually decreases from top to bottom; the anti-vortex device 6 and the through hole 4 are all provided with a filter screen 5 ; The distance between two adjacent through holes 4 gradually decreases from top to bottom.

[0042] In some embodiments, the number of through holes 4 is six.

[0043] When in use, the liquid discharge pipe 8 is opened, and nitrogen gas is ...

Embodiment 2

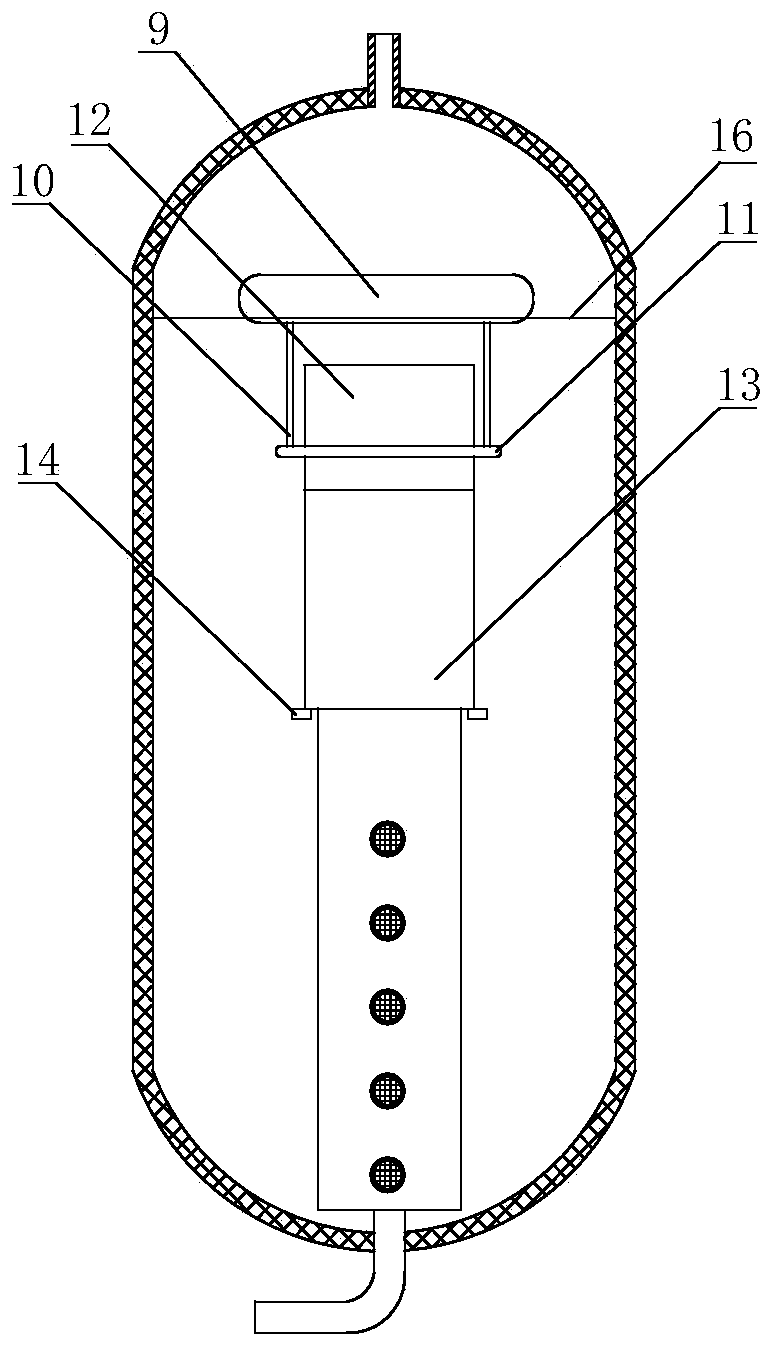

[0045] Such as figure 2 As shown, on the basis of Embodiment 1, it also includes a main floating plate 9 above the standpipe 3, the lower surface of the main floating plate 9 is connected with an extension tube through a connecting mechanism, and the extension tube is sleeved on the standpipe 3 Externally, the top of the extension tube is an open end, and there is a gap between the top of the extension tube and the lower surface of the main floating plate 9; the length of the standpipe 3 is 1.2 to 2 times the length of the extension tube; The gap height of the lower surface of the floating plate 9 is 10-25 cm.

[0046] Such as figure 2 As shown, when the coolant level 16 is higher than the open end of the riser 3, the gap height between the extension tube and the main floating plate 9 is fixed, the distance between the initial coolant level 16 and the standard line, and the coolant The drop of the liquid level 16 will not change the distance between the coolant liquid leve...

Embodiment 3

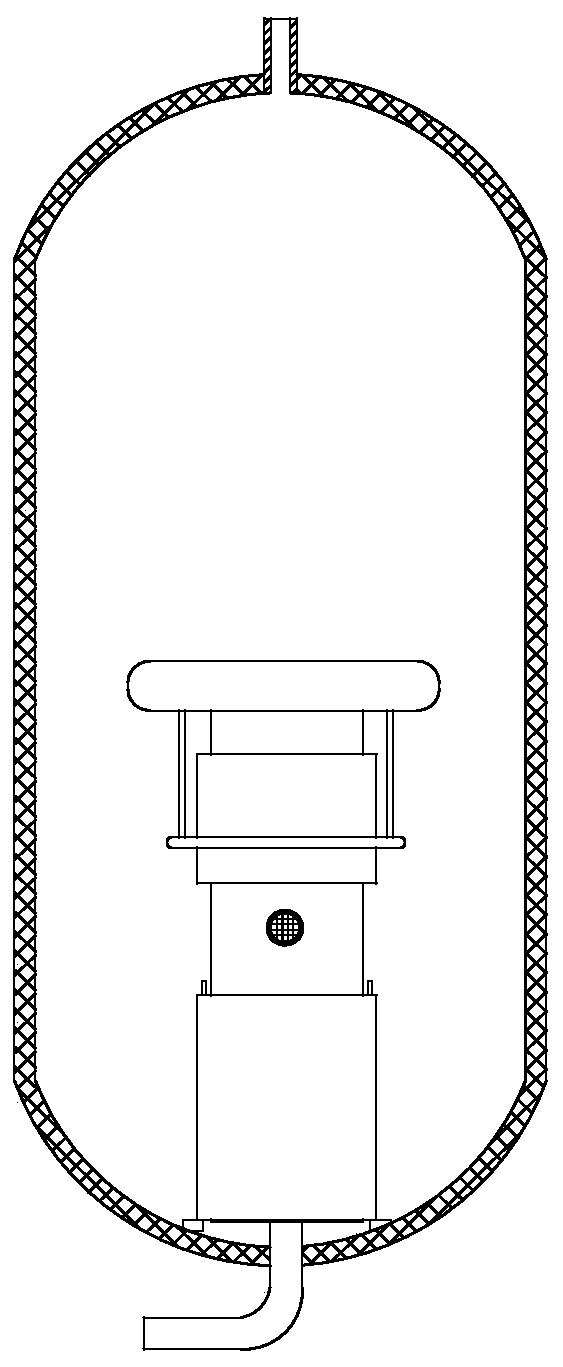

[0049] Such as Figure 2 ~ Figure 4 As shown, on the basis of Embodiment 2, the extension tube includes a first extension tube 12 and a second extension tube 13, wherein the first extension tube 12 is located above the second extension tube 13, and the connecting mechanism is connected with the first extension tube The bottom end of the second extension tube 13 is provided with an auxiliary floating plate 14; the connecting mechanism includes a connecting rod 10 and a connecting ring 11, the connecting rod 10 is fixed on the lower surface of the main floating plate 9, and the connecting rod 10 The bottom end is fixed with a connecting ring 11, and the connecting ring 11 is fixedly sleeved on the outside of the first extension tube 12; the top of the second extension tube 13 is provided with a card protrusion 15, and the bottom end of the first extension tube 12 is provided with a A card slot matching the card protrusion 15.

[0050] Such as figure 2 As shown, when the coola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com