Hazardous waste incineration process and system

A hazardous waste and process technology, applied in incinerators, combustion types, combustion equipment, etc., can solve the problems of incomplete incineration and high cost of exhaust gas treatment, and achieve the effect of ingenious design, simple structure and reduced scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings. The test methods used in the examples are conventional methods unless otherwise specified; the used materials, reagents, etc., are commercially available reagents and materials unless otherwise specified.

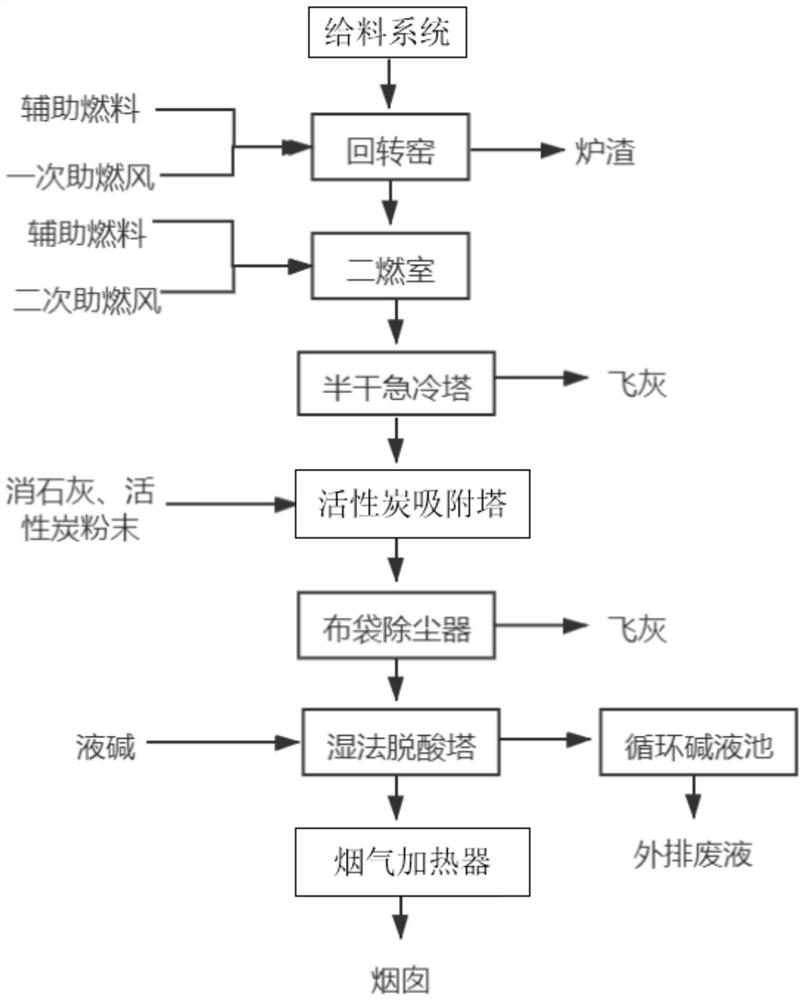

[0048] An embodiment of the present invention is: a hazardous waste oxygen-enriched incineration system, including a feed system, an incineration system (that is, a closely connected rotary kiln and a secondary combustion chamber) and an exhaust gas treatment system, and the feed system is used to transport the waste into the kiln It enters the incineration system, is incinerated by the incineration system, and then is purified by the tail gas treatment system before being discharged. Such as figure 1 As shown, the incineration system includes a closely connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com