Light olefin cracking equipment and cracking method

A low-carbon olefin and equipment technology, applied in the field of petroleum cracking, can solve the problems that crude oil cannot be directly used as cracking raw material and high cost of low-carbon olefin, and achieve the effect of saving process cost and reducing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

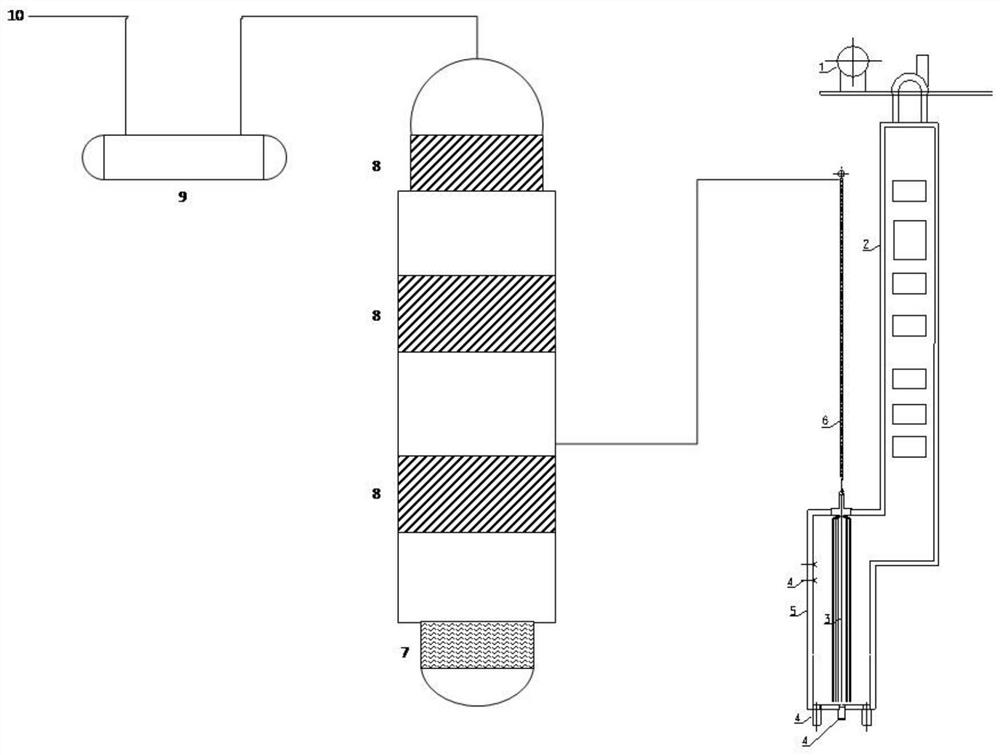

[0097] Adopt the light olefin cracking equipment provided by the invention (as figure 1 shown) for the cleavage reaction. The low-carbon olefin cracking equipment includes a fan 1 , a convection section 2 , a radiation section 5 , a quench boiler 6 , a reboiler 7 , a separation tower 8 , a condenser 9 , and a decompression device 10 .

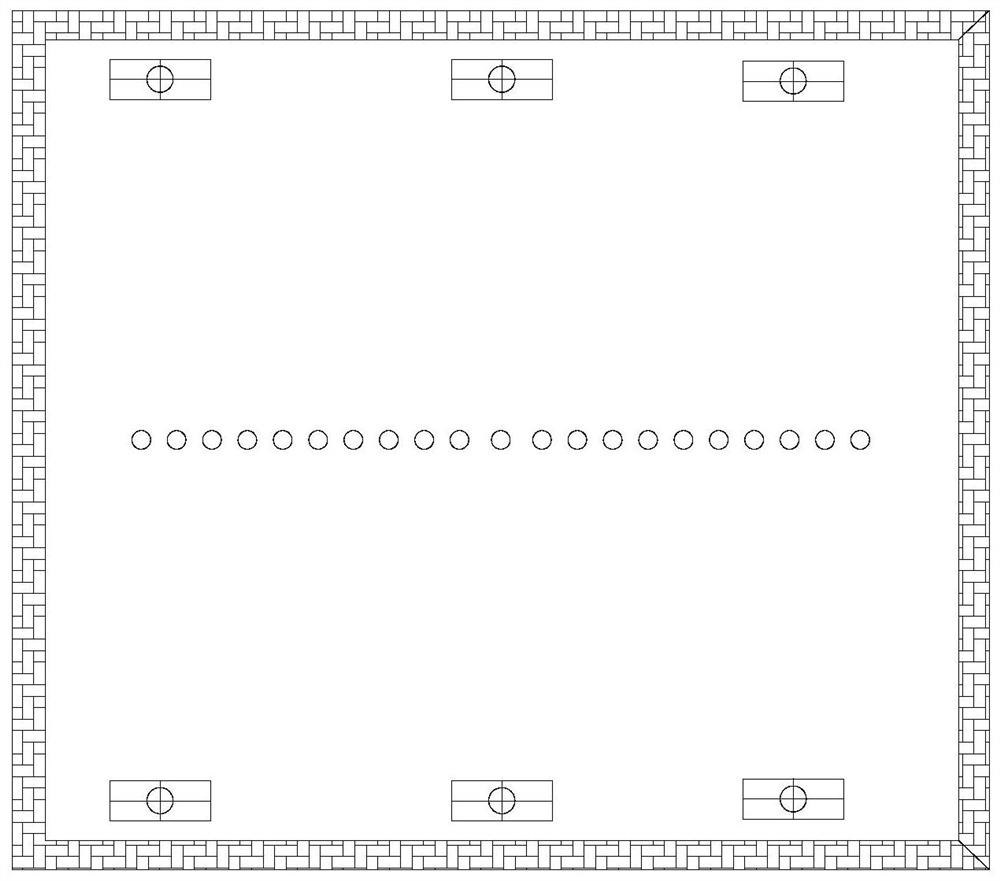

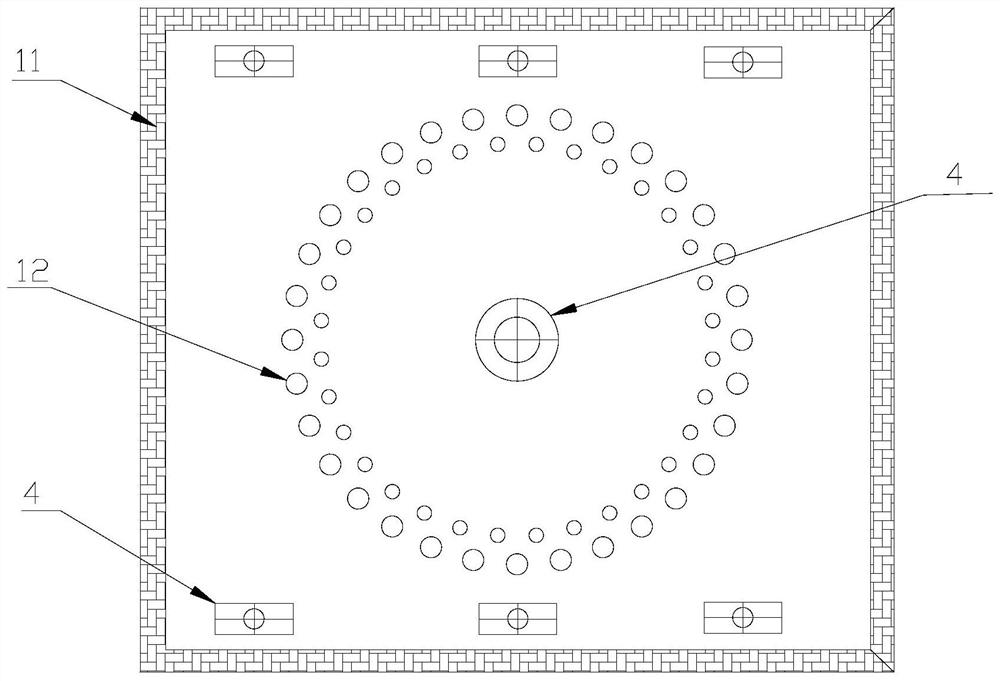

[0098] First, start the decompression device 10, and control the pressure of the equipment at 5KPa, so that the equipment is in a negative pressure state; the crude oil after removal is gasified and preheated through the convection section 2, and then enters the radiant section furnace tube 3 for cracking reaction; The combustion system of radiant section 5 adopts the combination of bottom burner and side wall burner, the heat supply ratio of the bottom burner is 80%, and the burner uses oxygen-enriched air for combustion, and the oxygen concentration in the oxygen-enriched air is 30% (V / V). The preheating temperature of crude oil in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com