Method for maintaining and replacing natural gas pipeline

A natural gas pipeline and pipeline technology, which is applied in the field of natural gas pipeline maintenance and replacement, can solve problems such as waste of liquid nitrogen resources, and achieve the effect of improving replacement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

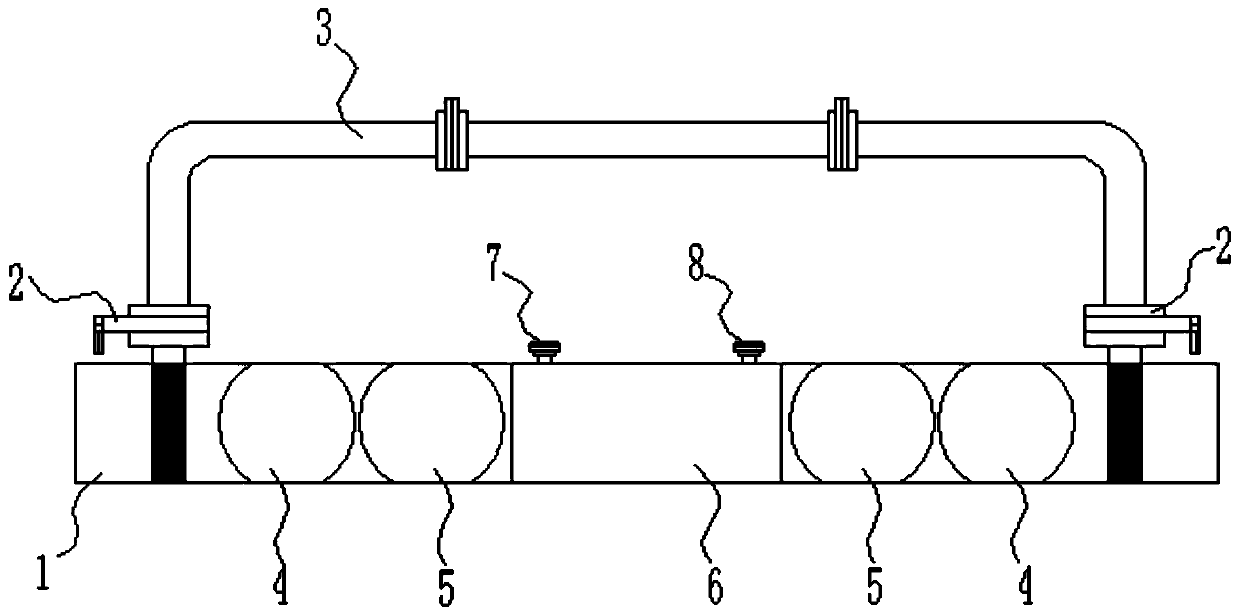

[0028] Such as Figure 1-3 As shown, the present invention discloses a method for repairing and replacing pipes of natural gas pipelines. The method for repairing and replacing pipes includes the following steps: step 1, close the upstream and downstream splint valves in the accident section and vent them, step 2 connect the bypass pipeline, and step 3 weld open Holes are shorted, step 4 is the first layer of isolation bag, step 5 is the rectangular ventilator, step 6 is sealing the opening, step 7 is the second layer of isolation bag, step 8 is the rectangular ventilator, step 9 pipe cutting, step 10 Take the isolation bag and weld the replacement tube.

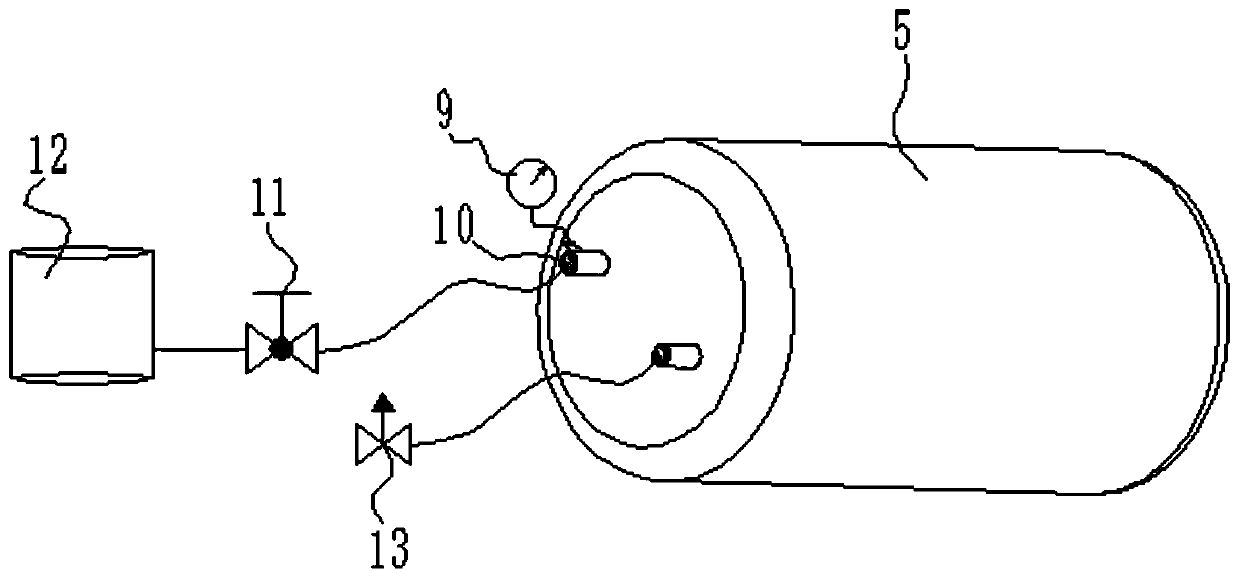

[0029] The nitrogen used to replace the natural gas in the accident section 6 comes from the vaporization of liquid nitrogen.

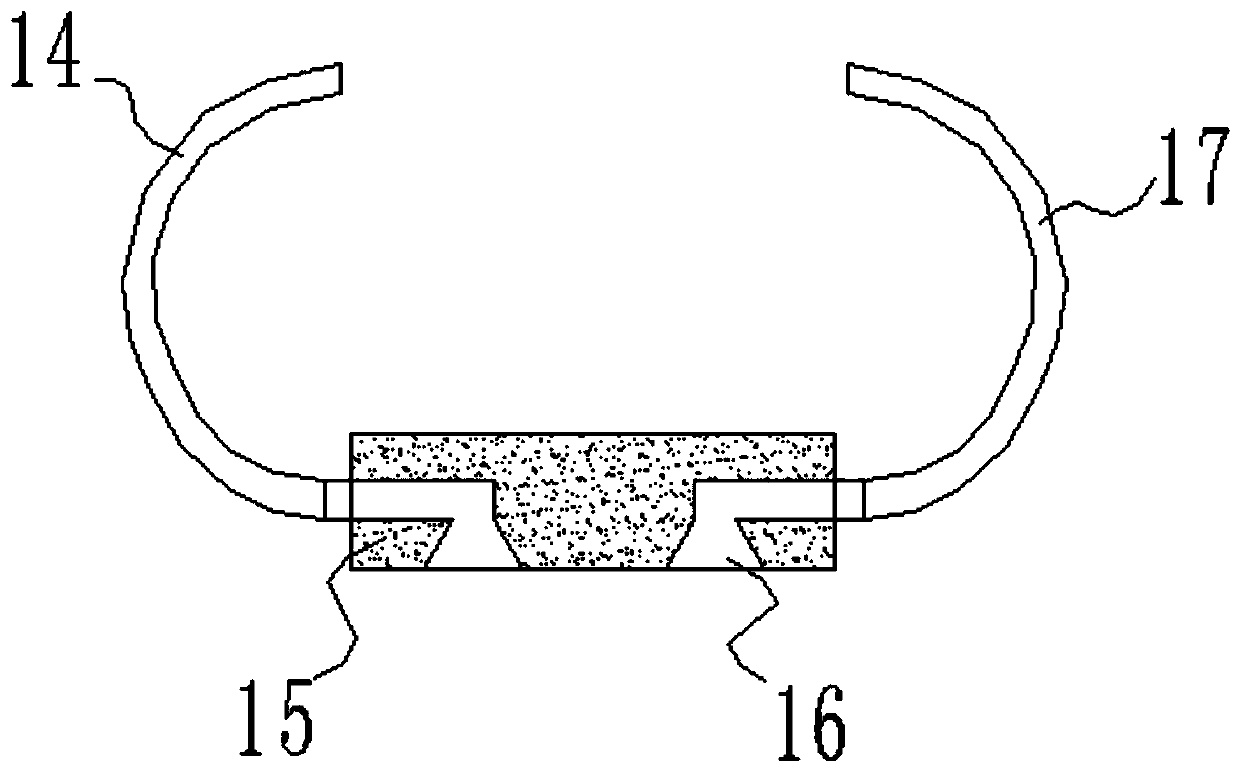

[0030] The two T-shaped slots 16 in the rectangular ventilator 15 are arranged symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com