A kind of environmental protection straw feed manufacturing equipment

A technology of straw feed and manufacturing equipment, which is applied in the direction of feed, cutting equipment, agricultural machinery and implements, etc. It can solve the problems of slowing down the crushing speed, easy to get stuck inside the extrusion hole, and slowing down the speed, so as to reduce the volume, The effect of keeping the extrusion hole unblocked and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Figure 5 Shown:

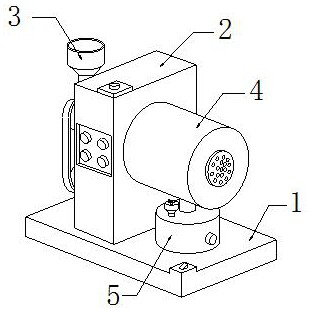

[0030] The invention provides an environment-friendly straw feed manufacturing equipment, the structure of which includes a base 1, a body 2, a hopper 3, a crushing cylinder 4, and a bucket 5. The bottom surface of the body 2 is fixed on the left upper surface in the middle of the base 1. Located on the left side of the top of the body 2, the left end of the crushing tube 4 is horizontally welded to the right side of the body 2, and the top of the bucket 5 communicates with the bottom surface of the crushing tube 4 near the right end.

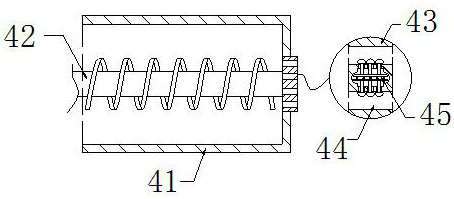

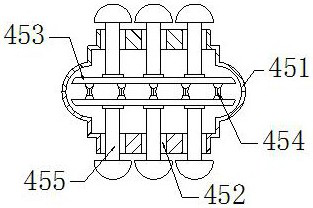

[0031] The crushing cylinder 4 includes a cylinder body 41, a crushing rod 42, a crushing plate 43, a crushing hole 44, and a crushing mechanism 45. The crushing rod 42 is arranged in the middle of the cylinder body 41, and the crushing plate 43 is nested and installed. On the surface of the middle part on the right side of the cylinder body 41 , the extruding hole 44 horizontally runs ...

Embodiment 2

[0038] as attached Figure 6 to attach Figure 9 Shown:

[0039] Wherein, the water bucket 5 includes a barrel body 51, a liquid inlet pipe 52, a connecting pipe 53, and a blocking mechanism 54. The bottom of the connecting pipe 53 is vertically fixed at the center of the top of the barrel body 51, and the liquid inlet pipe 52 is located at the top of the connecting pipe. 53 on the left side, the left and right sides of the blocking mechanism 54 are connected to the inner walls on both sides of the connecting pipe 53, and the top of the connecting pipe 53 is connected to the bottom surface on the right side of the cylinder body 41, and the liquid inside the bucket 5 can be transferred to the The inside of the barrel 41 is conveyed, so that the particles inside the barrel 41 are mixed with the liquid and extruded into granular form.

[0040] Wherein, the blocking mechanism 54 includes a cover plate 541, a connecting plate 542, and a spray hole 543, the outer wall of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com