Oil storage exhaust gas sealed recovering process by using self-produced surplus hydrogen

A hydrogen and oil depot technology, applied in the field of metallurgical coking, can solve problems such as the stability of the gas purification system affecting the quality of the gas and the increase in the exhaust gas volume, and achieve the effect of solving the problem of direct efflux, reducing the impact and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

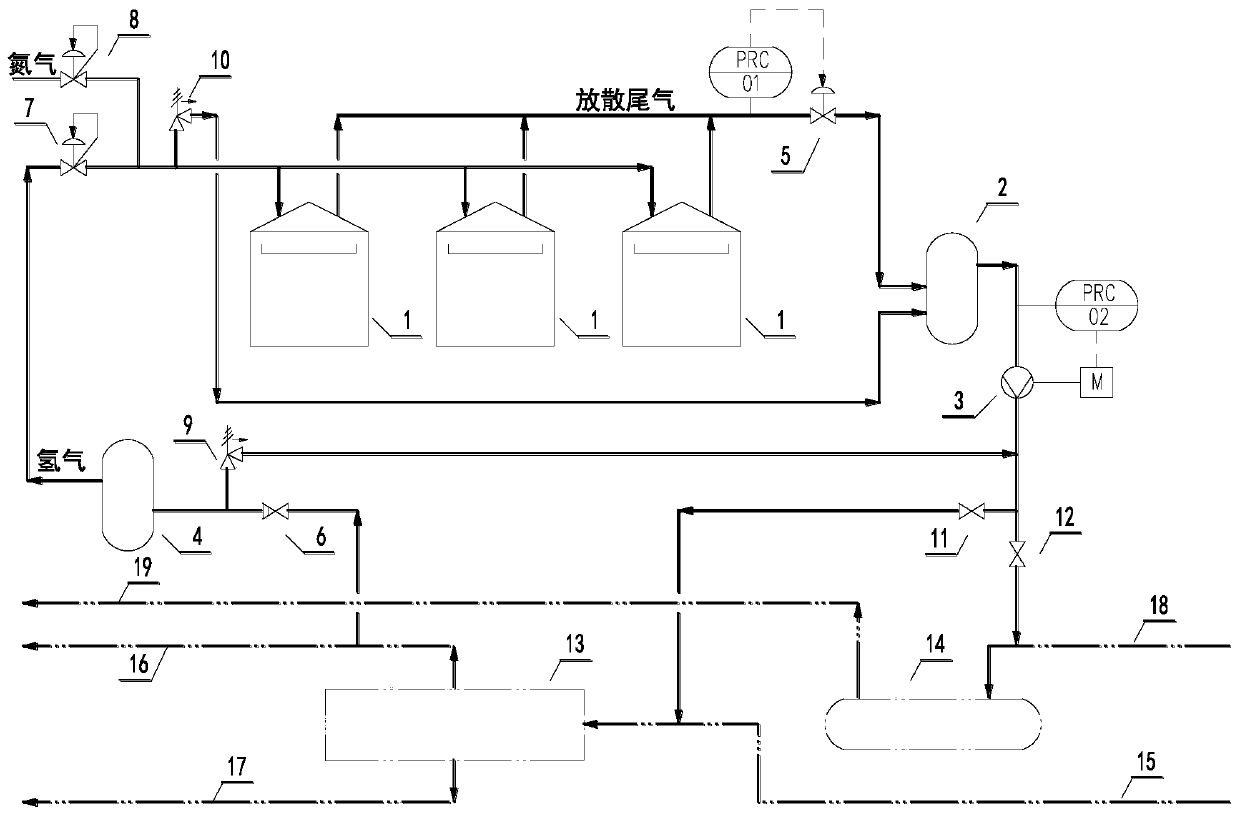

[0026] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0027] see figure 1 As shown, the present invention relates to a process for sealing and recovering tail gas from an oil depot by using self-produced surplus hydrogen gas, including the following steps:

[0028] 1) The sealing hydrogen is drawn from the hydrogen pipeline 16 of the PSA PSA pressure swing adsorption hydrogen production unit 13 to the main benzene hydrogenation unit, and is reduced to 0.1 MPa (1.6 MPa before the pressure reduction) through the pressure reducing valve 6 and then sent to the hydrogen buffer Tank 4, after buffering, passes through the hydrogen self-supporting regulating valve 7 to control the valve and the pressure is 50kPa, it is connected to the headspace of each oil depot 1 to implement hydrogen sealing of each oil depot;

[0029] 2) The vented exhaust gas is drawn from the vent on the top of each oil depot 1, and is controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com