Mixed Refrigerant Liquefaction Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

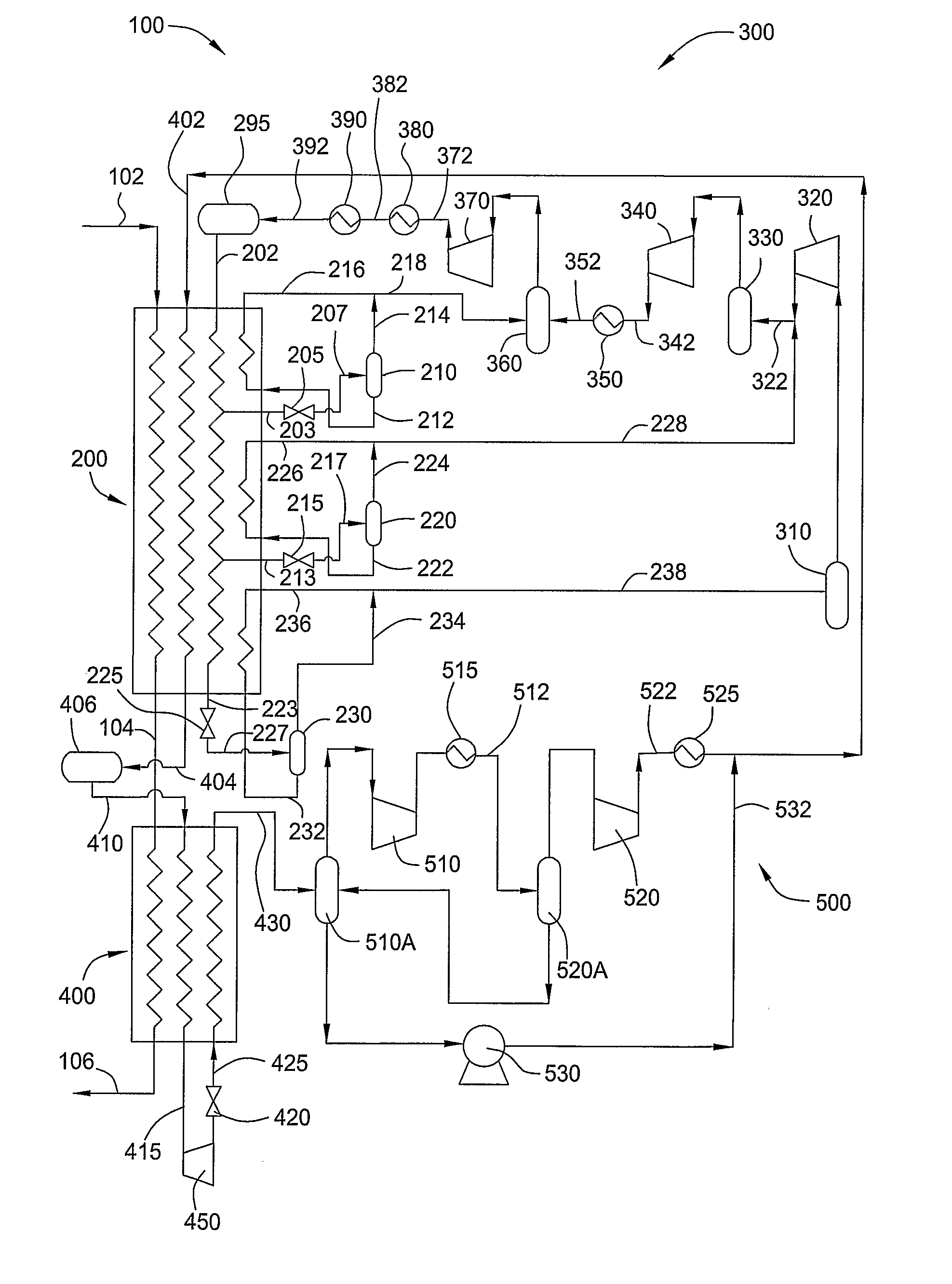

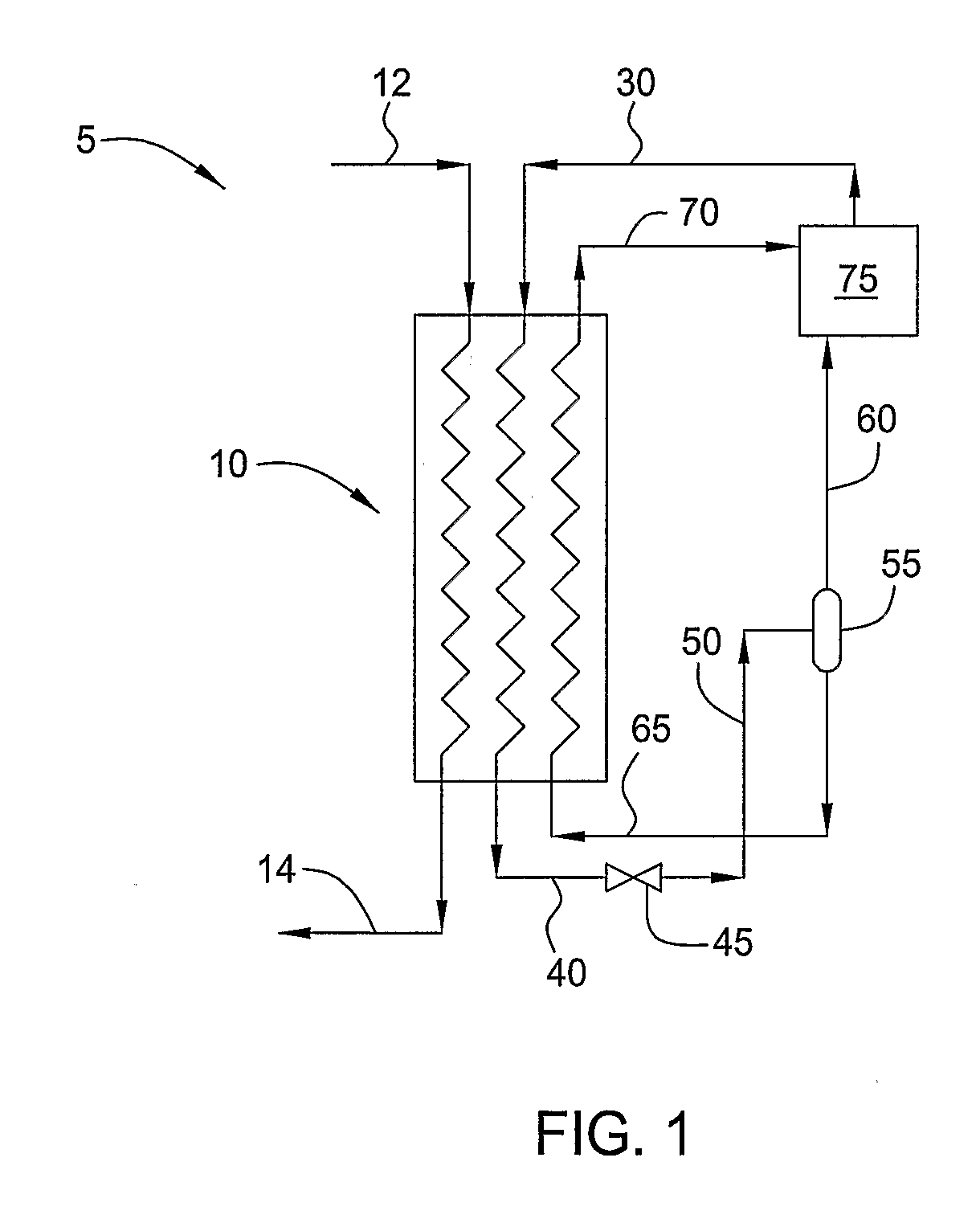

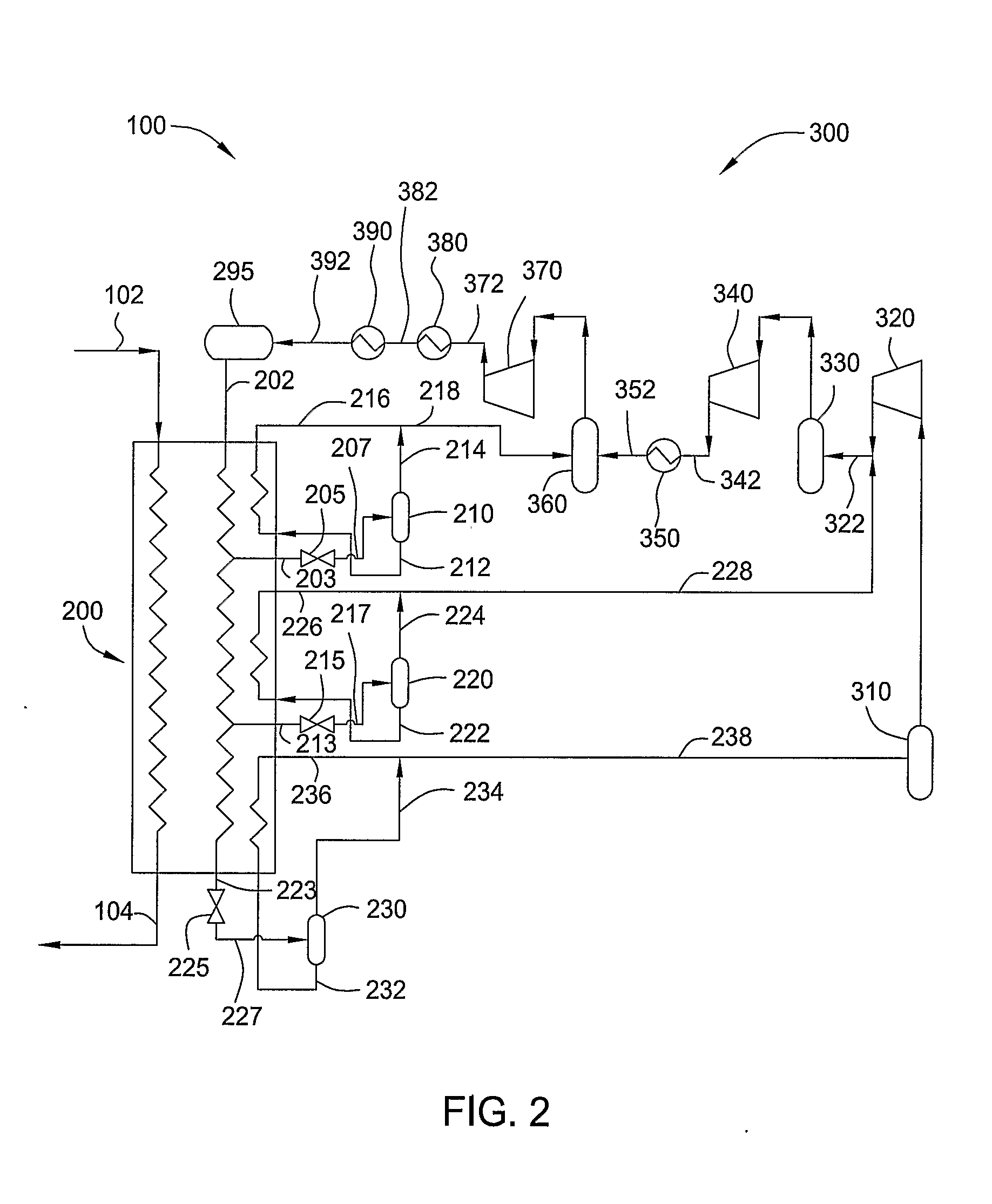

[0021] Various specific embodiments are described below, at least some of which are also recited in the claims. For example, at least one embodiment is directed to a method for liquefying a natural gas stream by placing a mixed component refrigerant in a heat exchange area with a process stream and separating the mixed component refrigerant at one or more pressure levels to produce a refrigerant vapor and a refrigerant liquid. The refrigerant vapor bypasses around the heat exchange area to a compression unit, and the refrigerant liquid passes to the heat exchange area.

[0022] At least one other specific embodiment is directed to liquefying a natural gas stream by placing a mixed component refrigerant in a heat exchange area with a process stream and withdrawing two or more side streams of the mixed component refrigerant from the heat exchange area. The side streams of mixed component refrigerant are then separated at one or more pressure levels to produce refrigerant vapors and refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com