Production method of high-temperature heating modified rubber wood floor

A modified rubber and production method technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of no improvement in termite prevention performance, vulnerability to termite erosion, termite hidden dangers, etc., and achieve excellent dimensional stability, Reduce process time and energy consumption, resist moth and termite infestation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

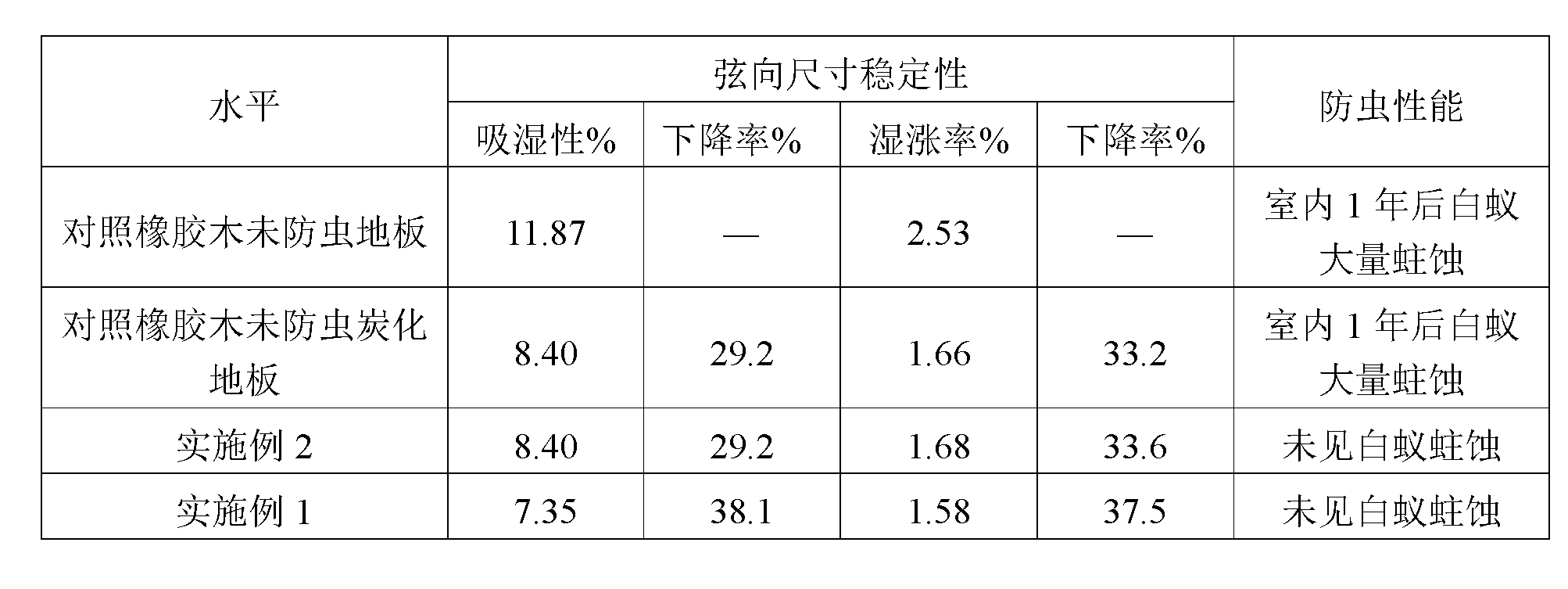

Examples

Embodiment 1

[0020] 1) Saw the rubber wood log into a rectangular thick wood square with a size of 7.5cm×14cm×100cm.

[0021] 2) Put the wooden stacks into the vacuum treatment tank, use the boride aqueous solution as the treatment liquid for vacuum pressure impregnation, and carry out insect and termite treatment;

[0022] The borides in the treatment liquid are boric acid and sodium tetraborate, wherein the mass concentration of boric acid is 5%, and the mass concentration of sodium tetraborate is 5%. Vacuum for 20 minutes before, then pressurize for 1 hour, the pressure is 1.2MPa, insect-proof and termite-proof treatment is carried out, and the boron equivalent in the wooden square is controlled to 10.2kg / m 3 .

[0023] 3) Dry the artificial kiln of the rubber wood square treated with pest control and termite control to a moisture content of 20%~30%;

[0024] 4) Put the dried wood into the carbonization treatment equipment, raise the temperature to 45°C for 1 hour, then gradually rais...

Embodiment 2

[0027] 1) Saw the rubber wood log into a rectangular blank with a size of 2.5cm×14cm×100cm.

[0028] 2) Stack the rectangular billets into a vacuum treatment tank, and use the boride aqueous solution as the treatment liquid to vacuum pressurize and impregnate to prevent insects and termites;

[0029] The borides in the treatment liquid are boric acid and sodium tetraborate, wherein the mass concentration of boric acid is 4%, and the mass concentration of sodium tetraborate is 4%. Vacuum for 10 minutes before, then pressurize for 0.5 hours, pressure 0.8MPa, anti-insect and termite treatment, control the boron equivalent in the billet to 8.0kg / m 3 .

[0030] 3) Artificially kiln-dry the rubber wood billet treated with insect-proof and termite-proof to a moisture content of 12%;

[0031] 4) Put the dried billets into the carbonization treatment equipment, raise the temperature to 60°C for 1 hour, then gradually raise the temperature to 100°C, the heating time is 12 hours, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com