Production method of carbonized wood

A production method and technology for carbonizing wood, applied in the direction of burning charcoal/combustion, etc., can solve problems such as unfavorable environmental protection and increased cost, and achieve the effects of being beneficial to environmental protection, short treatment period, and high utilization rate of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

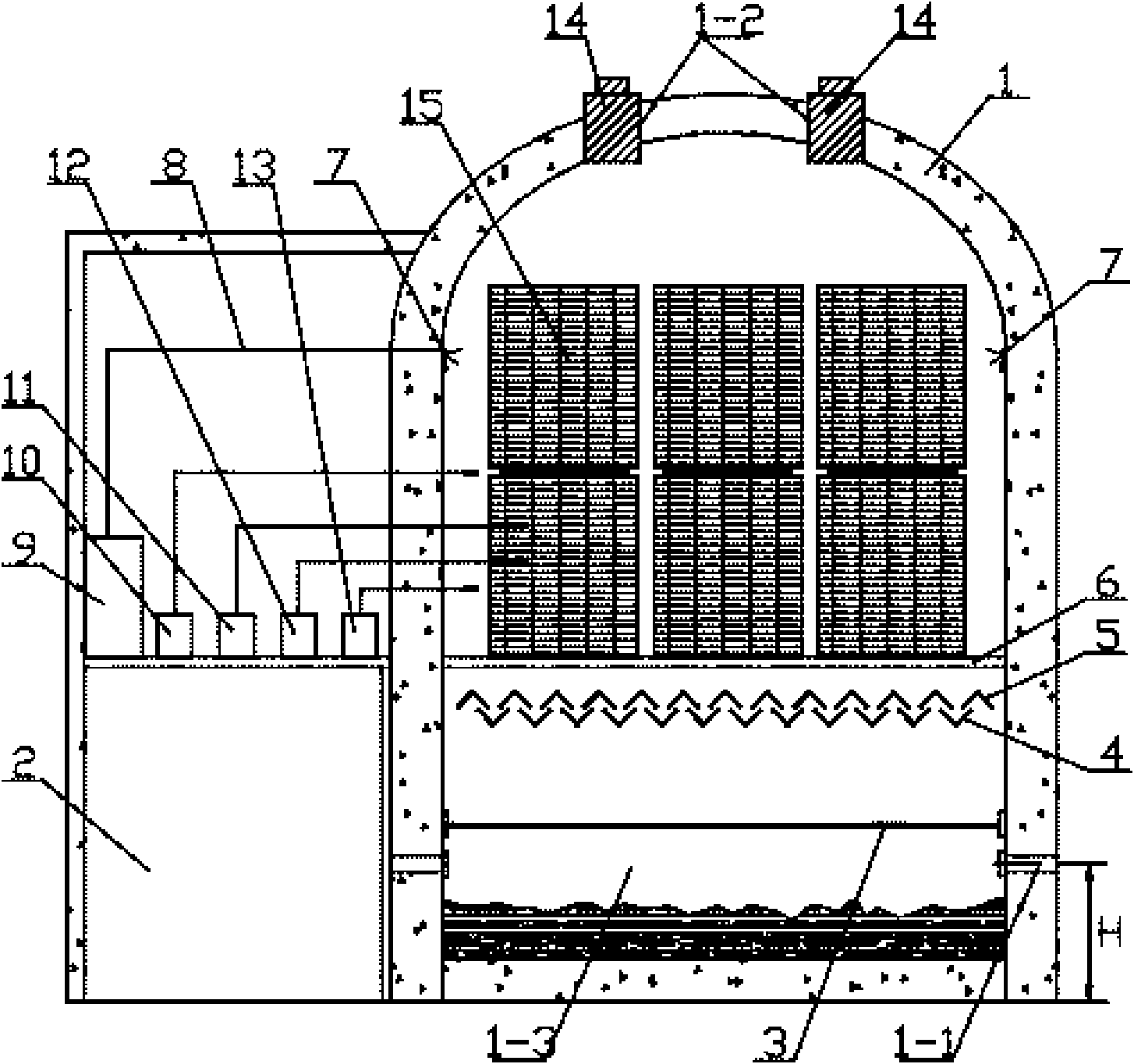

[0007] Specific implementation mode one: combine figure 1 Illustrate present embodiment, present embodiment is realized by following steps: one, several pieces of dry timber 15 that need to be processed are stacked on the support steel beam 6 in the carbonization treatment kiln 1 from bottom to top, between each piece of timber 15 The distance between them is consistent with the thickness of the wood 15 to meet the uniform flow of hot air from bottom to top; 2. Close the kiln door of the carbonization treatment kiln 1, open the air inlet 1-1 and the exhaust hole 1-2; 3. Ignite and burn The biomass material in the chamber 1-3, the hot air current that the biomass material after burning produces directly the wood 15 in the carbonization treatment kiln 1 is heated; The size of the exhaust hole 1-2 is controlled at 15-20° C. / h to adjust the heating rate of the inner chamber of the carbonization treatment kiln 1. During the heating process, water vapor is intermittently sprayed to ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the biomass material in Step 3 of this embodiment is sawdust or crushed straw. Biomass materials come from a wide range of sources, such as waste from wood processing, wood chips left after wood processing, straw left over from harvesting various crops, and various biomass materials in nature can be used for it, expanding the biomass The scope and field of material utilization; the effective utilization of biomass materials in the method of the present invention reduces the demand for coal to a certain extent, which is in line with the national policy of energy conservation and emission reduction; carbonized wood is produced by utilizing the heat and gas generated by the combustion of biomass materials, It has truly achieved turning waste into treasure. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 To describe this embodiment, the temperature rise rate of the inner cavity of the carbonization treatment kiln 1 in Step 4 of this embodiment is controlled at 18° C. / h. This heating rate can ensure that the wood will not be deformed during the heat treatment. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com