A formaldehyde-free bamboo recombined plastic building structural material and its preparation process

A technology of building structure and preparation process, applied in the direction of manufacturing tools, wood processing appliances, wood treatment, etc., can solve the problems of insufficient strength, damage to the internal structure of bamboo, planing and milling of fibrous biomass, etc. Mechanical properties, reduction of processing steps, effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

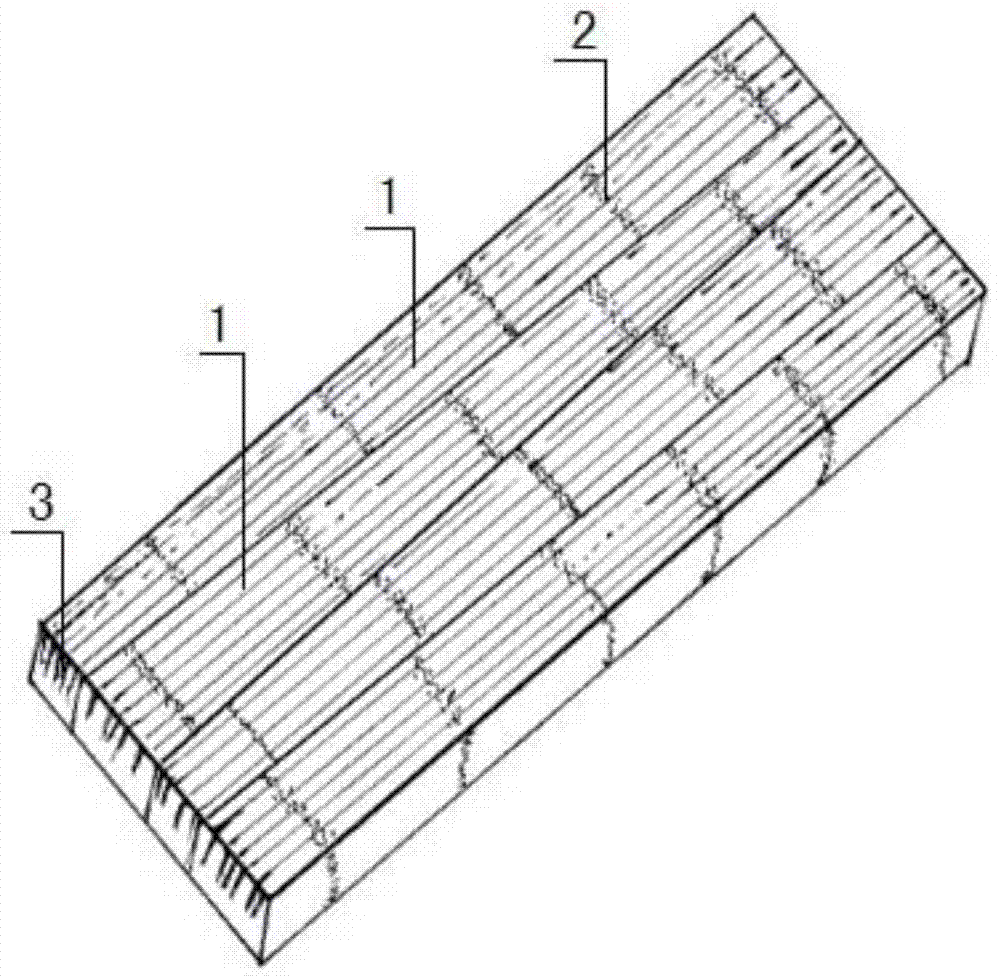

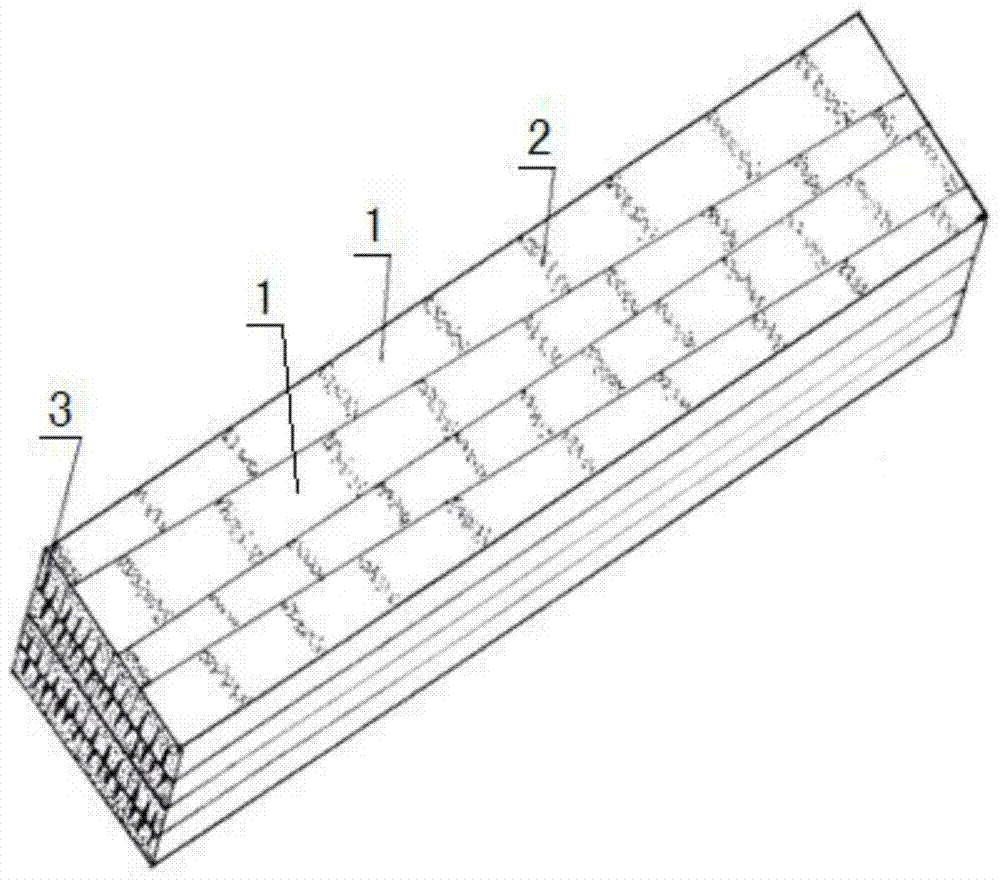

[0037] see figure 1 , is a structural schematic view of the bamboo re-plastic poly veneer of the present invention. from figure 1 It can be seen in the figure that the unfolded bamboo recombined plastic veneer is made of arc-shaped bamboo slices to remove the bamboo inner nodes, the bamboo yellow layer is split longitudinally, the bamboo green layer is connected, flattened, the bamboo green surface wax layer and the bamboo yellow surface are processed into Bamboo chip 1 with fixed width and thickness, pre-plasticized and modified bamboo material and paving treatment with polymer resin compound, the bamboo yellow side of bamboo chip 1 is the same side, the bamboo green side is the same side, and the sides are close to each other. The veneers that are arranged tightly and neatly; figure 1 Among them, 2 is the bamboo joint of the bamboo chip 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com