Control method for producing conical plate blank using side compression machine of fixed width plate blank

A control method and side press technology, applied in the direction of metal rolling stands, metal rolling mill stands, etc., can solve the problems of increased manufacturing cost, poor precision, no cone billet rolling, etc., to speed up logistics turnover, The effect of reducing quality fluctuations and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

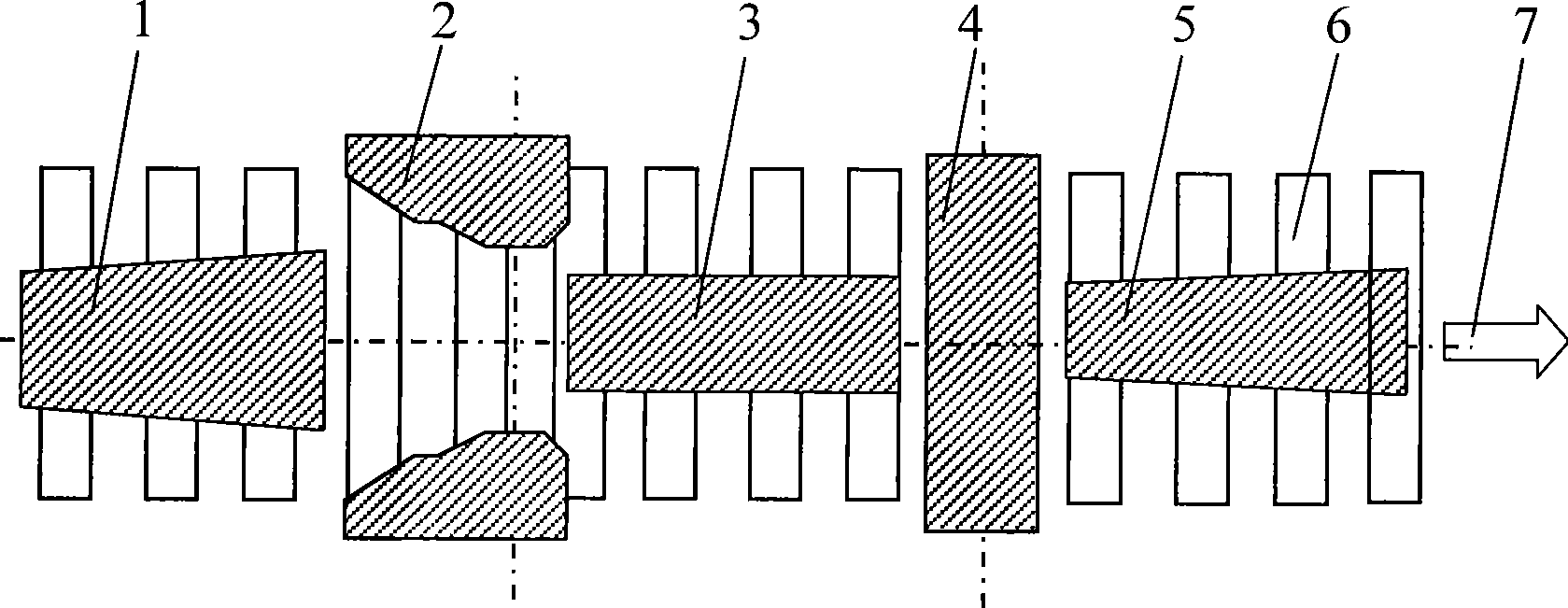

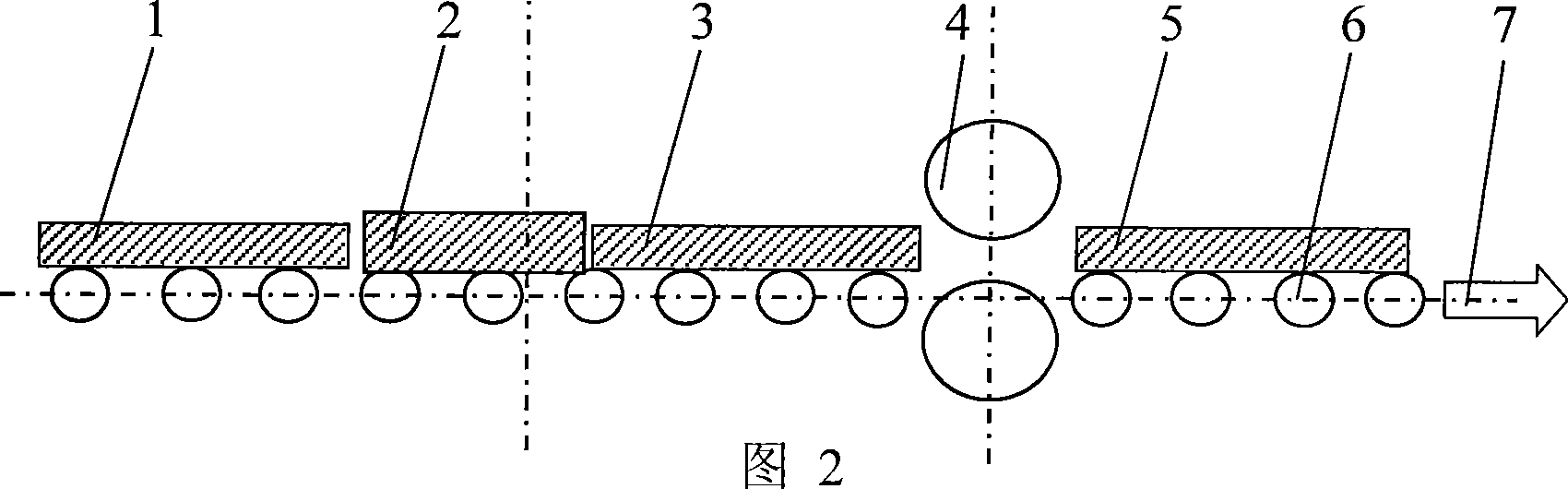

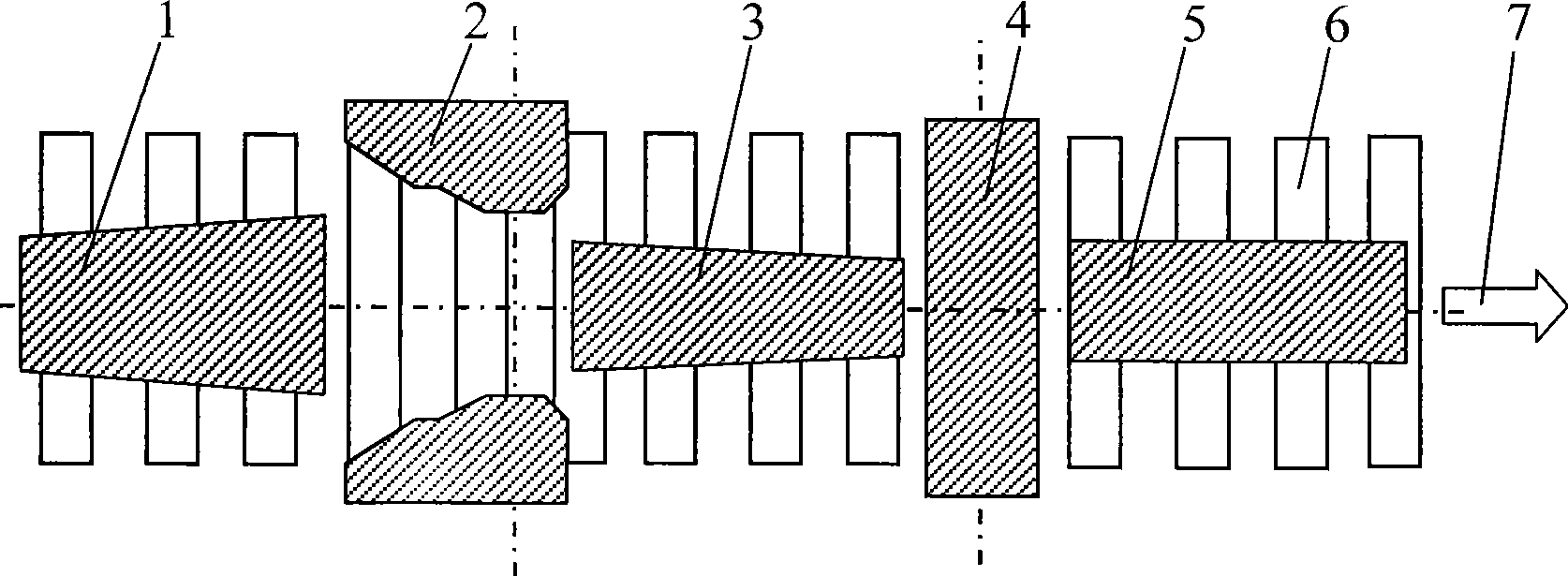

[0153] The present invention takes a conical blank (classification two) as example to illustrate as follows in conjunction with accompanying drawing:

[0154] (1) Judging the shape of the conical billet, the process control computer is based on the description data of the conical billet shape downloaded from the host computer, see Figure 8 , the width of the large end of the tapered billet is 1200mm, the width of the small end is 1100mm, the starting position of the widening is 841mm, and the length of the widening is 5197mm. According to the classification definition of the tapered billet, it can be judged as classification 2, and mode 2 is used for calculation and control.

[0155] (2) According to the shape expression data of the conical blank in (1), extract the characteristic value of the conical blank, extract the feature point PointA by the width of the large end of the conical blank and the starting position of the widening, and use the width of the small end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com