Control method of edge portion strip shape of cold rolling strip steel

A technology of strip shape control and strip edge, which is applied in the direction of contour control, etc., can solve the problems of not being able to give full play to the rapid response of bending rolls, not being able to reflect small deviation waves in the area near the edge, and long delays in strip shape detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

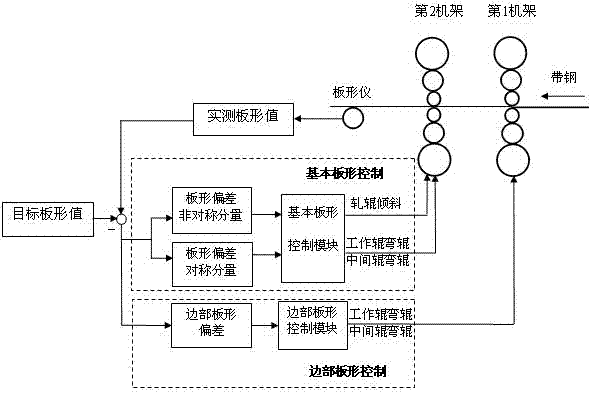

[0173] Taking the double-frame six-roller UCM skin pass mill as an example, the implementation process of the strip edge shape control method of the present invention is supplemented as follows.

[0174] Such as Figure 5 As shown, the equipment composition relevant to the present invention in the two-frame six-roller UCM skin pass comprises:

[0175] 1) The first frame of the tempering machine has upper and lower work rolls, upper and lower intermediate rolls, upper and lower support rolls, which are used to control the roll tilt of the steel plate shape at the exit of the frame, symmetrical bending rolls of the work rolls, and intermediate rolls. Symmetrical bending rolls, and plate-shaped actuators such as axial long-stroke roll shifting of intermediate rolls, etc.

[0176] 2) The second frame tempering machine has upper and lower work rolls, upper and lower intermediate rolls, upper and lower support rolls, which are used to control the roll tilt of the steel plate shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com