Transverse car body conveying system

a conveying system and car body technology, applied in transportation and packaging, propulsion railway systems, rope railways, etc., can solve the problems of high conveying power requirement, low storage efficiency, and high carrier weight, and achieve stable carrier travel and high storage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

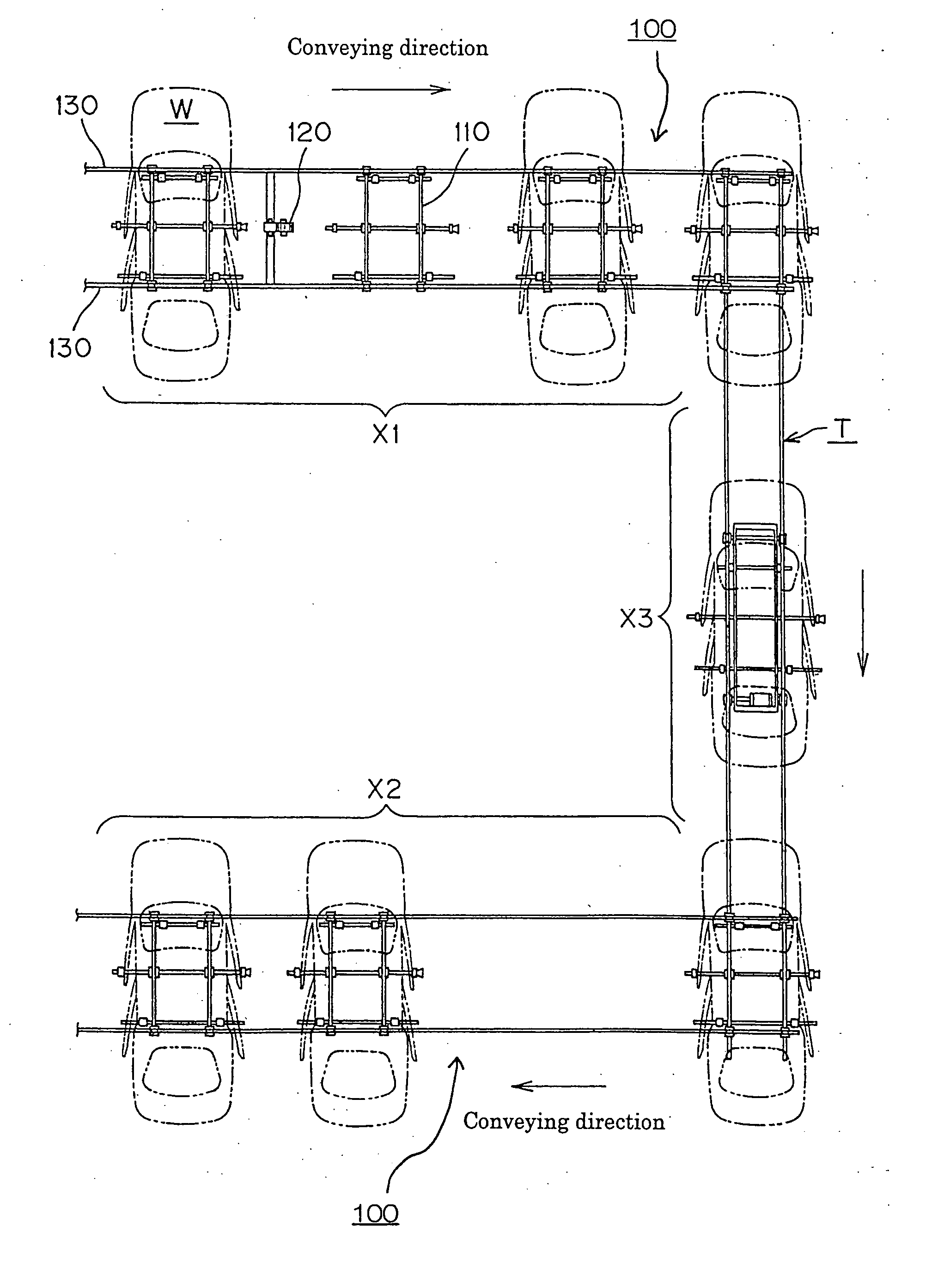

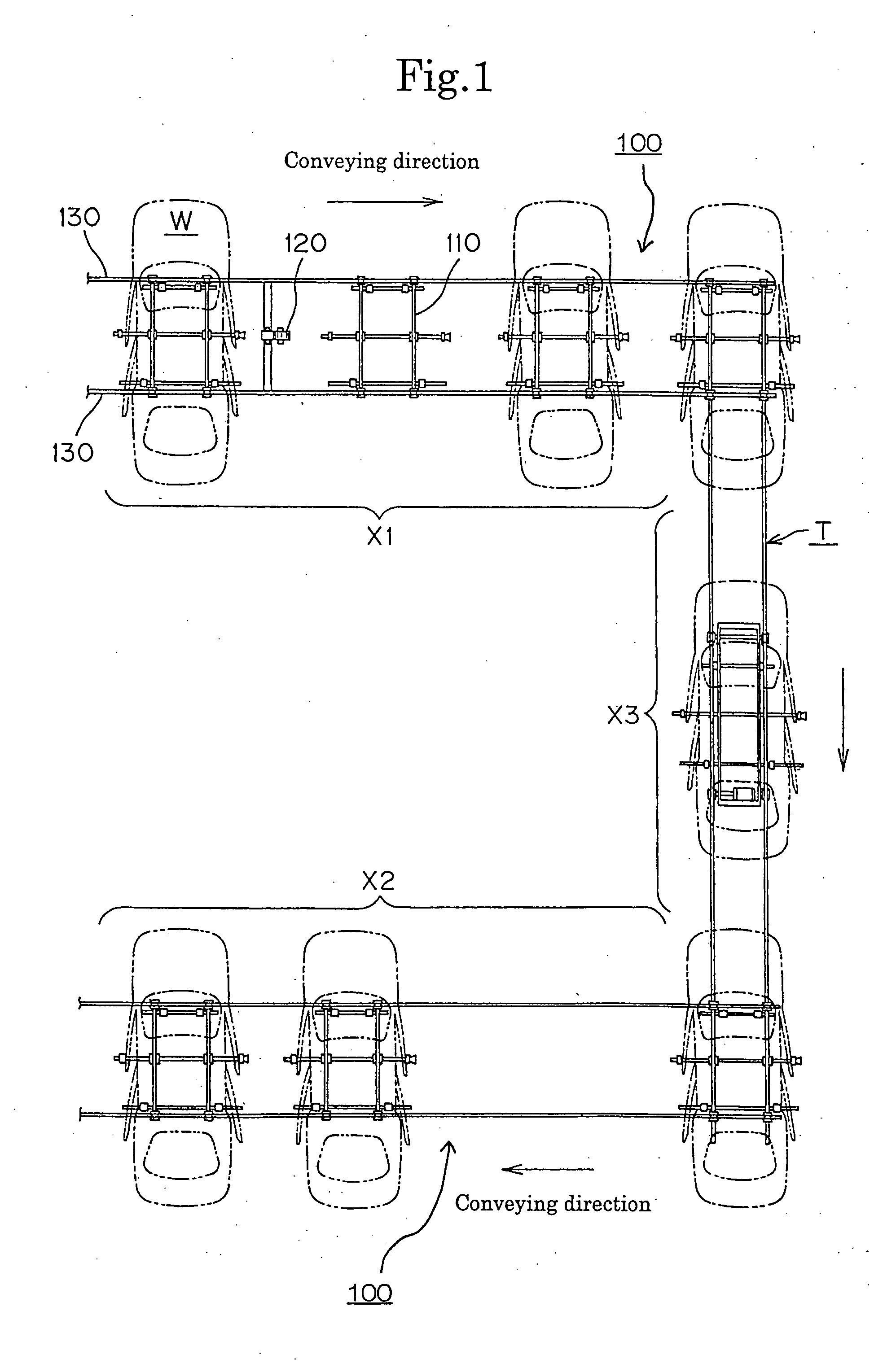

[0022] In the transverse car body conveying system shown in FIG. 1, car bodies may be transported along conveying path X1 in a painting step, and along conveying path X2 in a drying step. The car bodies are transferred along a conveying path X3 from passage X1 to passage X2 by a traverser mechanism T. Each of the car bodies is arranged so that its direction of elongation, i.e., its long dimension, is in transverse relationship to its direction of travel along passages X1 and X2, and the entire conveying system of FIG. 1 is generally C-shaped in plan view.

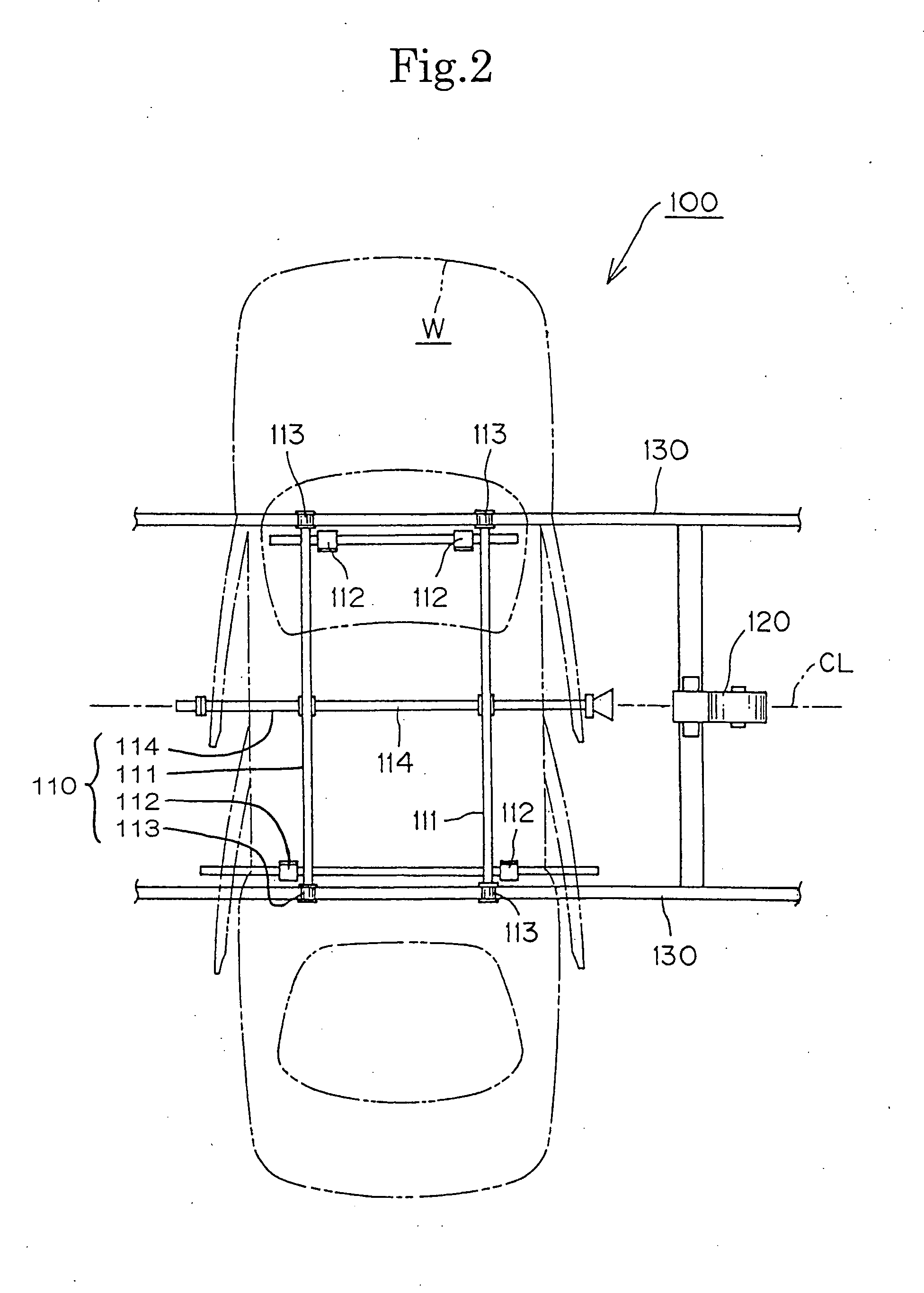

[0023] Skid-type carriers 110 for mounting the transversely oriented car bodies W, travel passively on a pair of left and right rails 130 provided along conveying paths X1 and X2. The carriers are propelled by driving forces imparted by friction drive rollers located along each of the car body conveying paths X1 and X2. The drive roller mechanism 120 for conveying path X1 is shown in FIG. 1.

[0024] The skid-type carrier 110 as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com