Alloy blends of polyurethane and rubber

a technology of polyurethane and blend, applied in the field of rubber formulation, can solve the problems of deficient gas barrier performance, deficient air retention or elastic properties, bladders or “cores” made of natural rubber, etc., and achieve the effect of improving barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0059] Exemplary embodiments of the present invention used PTMEG-based polyurethanes, Adiprene® CM (ACM) and Millathane® E-34 (ME34), and a polyester-based polyurethane, Millathane® M76 (MM76) (Adiprene and Millethane are trademarks of TSE Industries, Inc.). These polyurethanes are combined with rubbers to make the inventive barrier articles. Typically, the natural rubber and MPU are blended in e.g. a Banbury mixer along with additives and curatives until thoroughly mixed to achieve the desired consistency as described above. The natural rubbers employed are isoprene materials typically used in conventional sports balls. The natural rubber formulations are Standard Malaysian Rubber formulations, grade GP (SMR GP). SMR GP is processed from mixed latex and rubber sheets. Formula information for SMR GP sub-grades GP1, GP2, and GP4 are listed below in tables 1, 2 and 3.

TABLE 1GP1 Formula barrier article formulationGP1GP1FormulaFormulaIngredientDescriptionType(lb)(%)SMR GPNaturalRubber...

examples 1-12

[0062] MPU / rubber alloys were formed by mixing either Adiprene® CM (ACM), Millathane® E-34 (ME34), or Millathane® M76 (MM76) with a natural rubber component (SMR-GP) in proportions indicated in the tables below. The barrier articles further include about 50 wt % clay and other additives. For example, the description of Example 1, table 5, is for 50 / 50 ACM / SMR-GP a GP2 barrier article. The barrier article of Example 1 therefore contains 50 parts ACM and 50 parts SMR-GP based on weight and in addition includes the proportionate amount of fillers and additives of GP2 (table 2). Stated differently, Example 1 has the identical formulation as GP2 (table 2) except the amount of SMR-GP has been halved from 77.2 lbs to 38.6 lbs and replaced with 38.6 lbs of ACM.

[0063] As noted above in Tables 2 and 3, GP2 and GP4 barrier article formulations likewise included about 50 wt % clay and other additives. The results of permeability testing are presented in the table below. Example barrier article...

examples 13-24

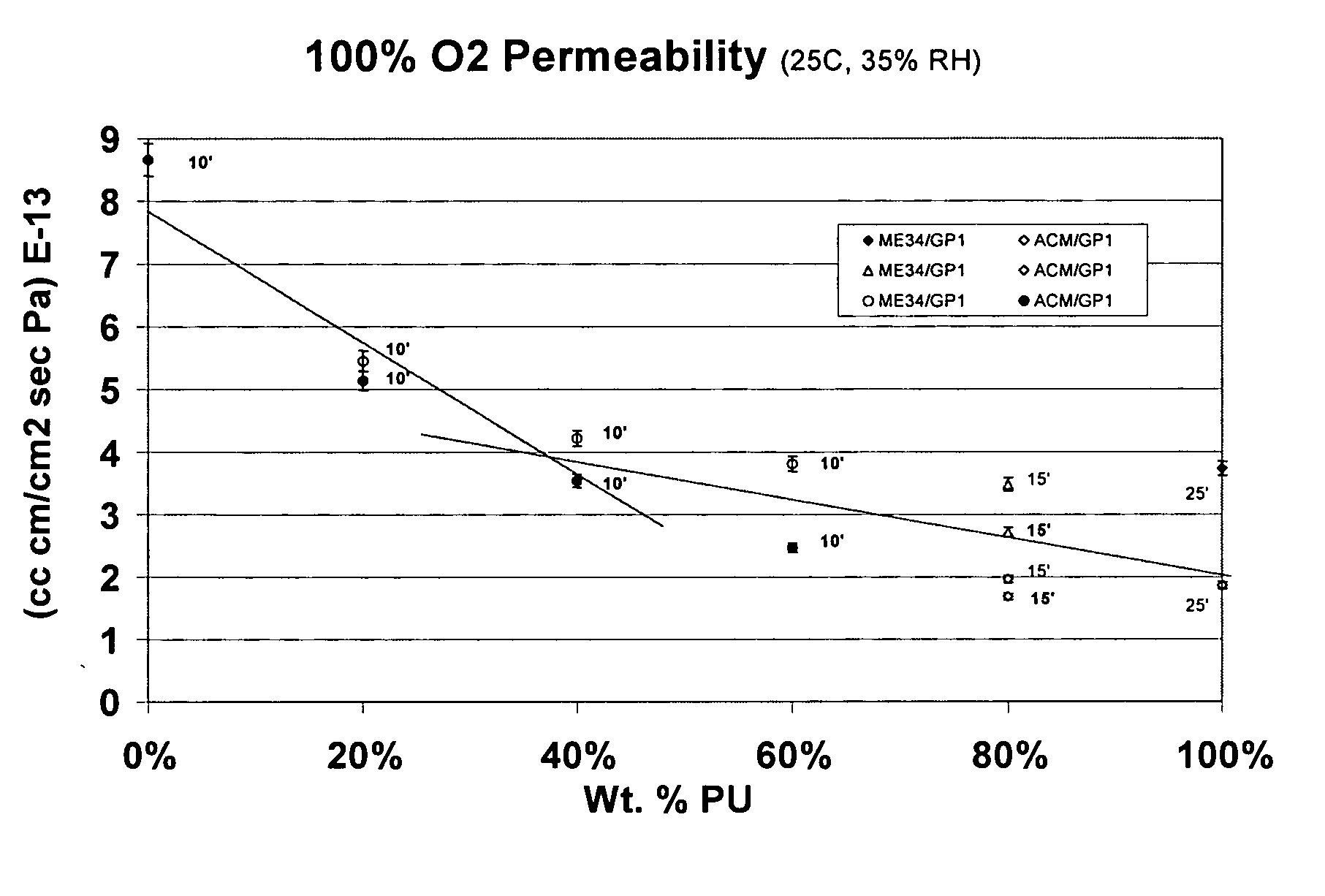

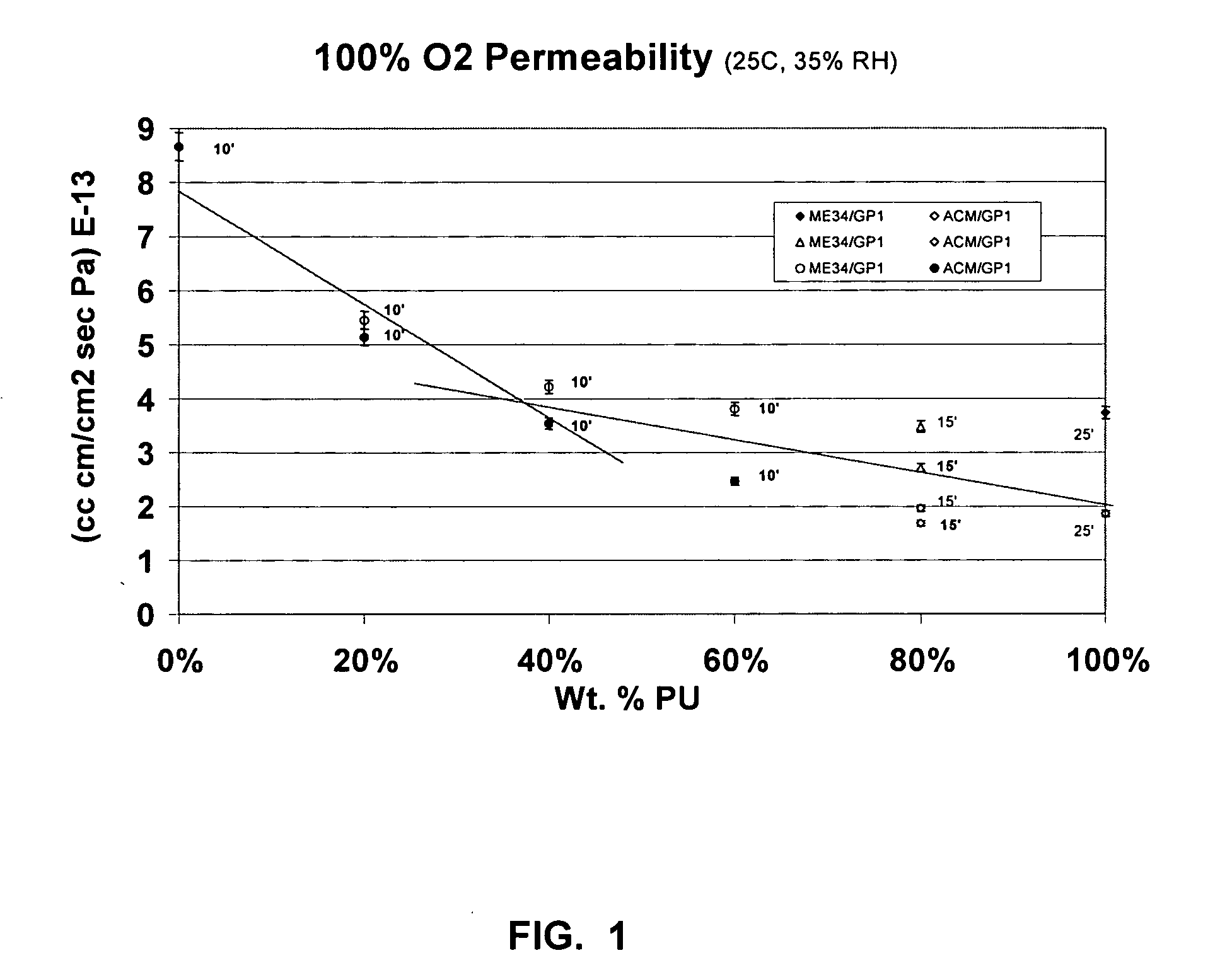

[0066] Barrier articles with alloys of MPU and GP1, and including about 50 wt % clay and other additives, gave improved permeability relative to barrier article controls GP2 and GP4 and showed a strong correlation of temperature and permeability. The materials were prepared as in Examples 1-12, but tested as sheet examples. Example E, a sheet example, was made from GP1.

TABLE 6Oxygen290FNominalTrans.Est. OxygenMillSampleRelativePressureRatePermeabilityTimeThicknessHumidityTemp.Gradient(21% O2)(cm3 cm / cm2 ·ExampleUnitsminmils%deg. C.mm Hgcc / m2 days · Pa) 10−13 13.20 / 80103435257601065.1ACM / SMR-GPGP1 barrierarticle14.40 / 6010323525760773.5ACM / SMR-GPGP1 barrierarticle15.60 / 4010433525760402.5ACM / SMR-GPGP1 barrierarticle16.80 / 2015343525760351.7ACM / SMR-GPGP1 barrierarticle17.80 / 2015273525760512.0ACM / SMR-GPGP1 barrierarticle20.80 / 2015273525760923.5ME34 / SMR-GPGP1 barrierarticle21.20 / 80103335257601155.5ME34 / SMR-GPGP1 barrierarticle22.40 / 6010343525760874.2ME34 / SMR-GPGP1 barrierarticle23.60 / 401...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen permeability | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com