Chamber of a peristaltic pump for tire pressure adjustment

a peristaltic pump and chamber technology, applied in the direction of tyres, tyre beads, tyre measurements, etc., can solve the problems of poor operation, high production cost, high cost and complexity of devices, etc., and achieves short operating life, rapid wear and tear, and high fineness and/or fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

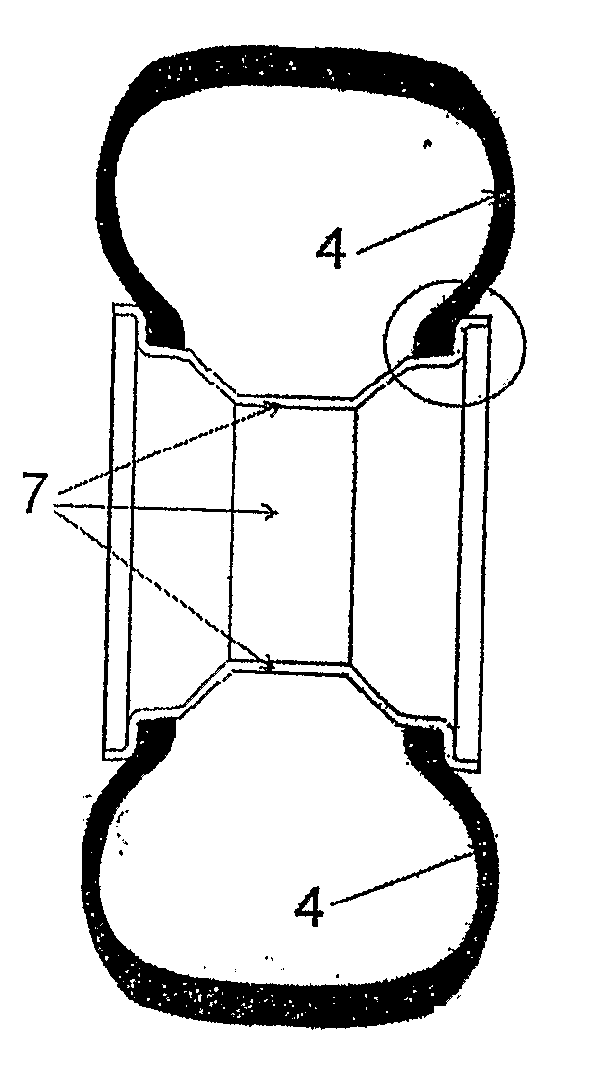

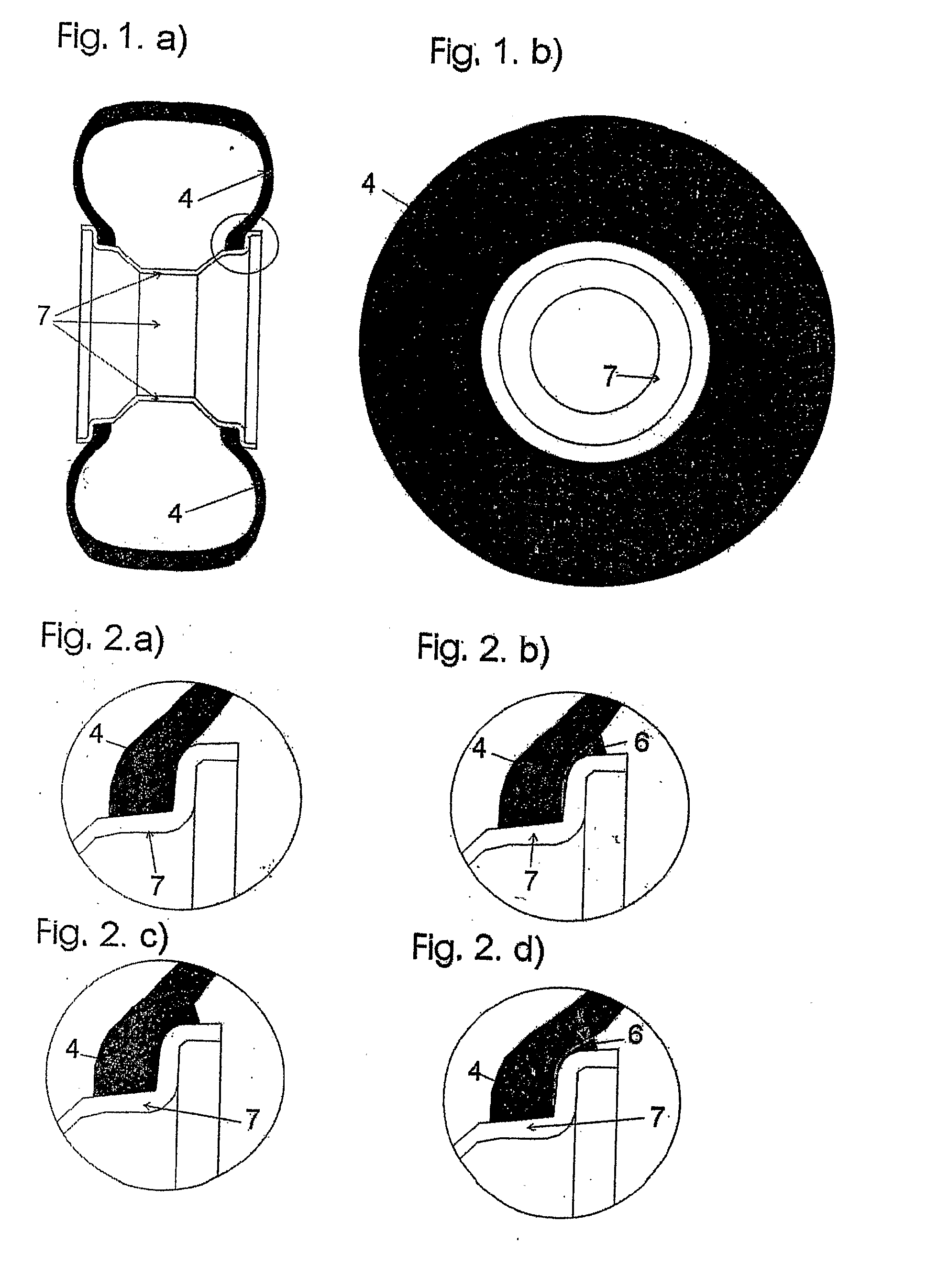

example 1

[0052]The chamber 1 with shape memory for pressure correction in the tire, which is a part of the tire or adjacent to the tire wall and is connected with the internal space of the tire at one end and with the exterior environment at the other end, has the shape of a curved hollow channel, with its enclosing wall partly formed by the pair of surfaces 10 lengthwise coplanar with the chamber 1 (channel) under the angle of α=2 to 15°. The angle α>0° is on the contacting edge of these surfaces 10 located on the further side from the center of the chamber 1 cross-section. The chamber 1 is placed in the area of the tire side wall 4 at its bead.

[0053]When manufacturing the chamber 1 a flat matrix 9 with a shaped protrusion and with a width of 0.8 mm and thickness of 0.02 mm, is inserted between the layers forming the tire side wall 4 before vulcanization, then the vulcanization is performed and the inserted matrix 9 is extracted as a whole towards the center axis 2 of the tire 4. The thickn...

example 2

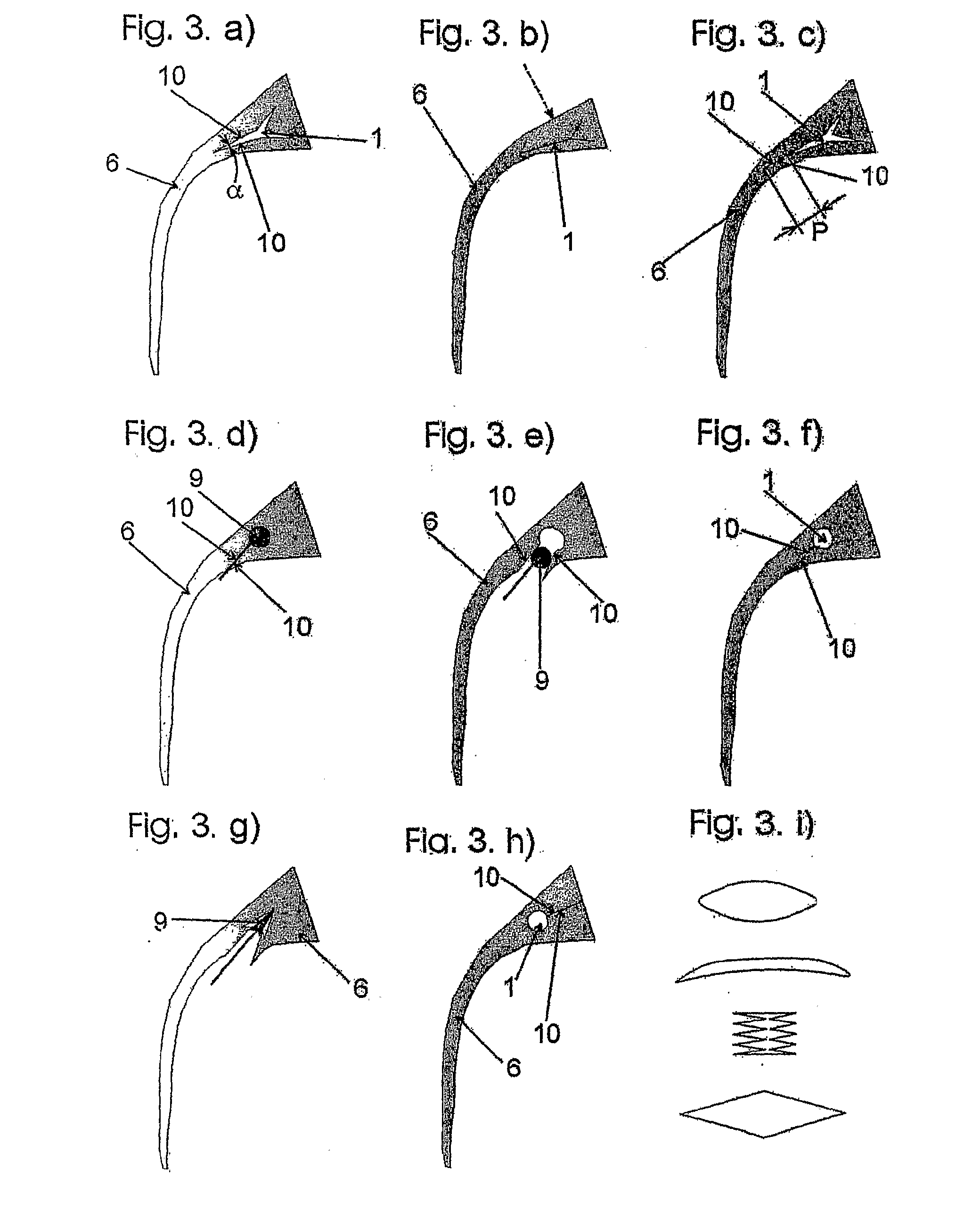

[0061]FIG. 3. a) shows the ancillary structure 6 containing the chamber 1 with the cross-section in the shape of a three-pointed star. This part of the chamber 1 is placed on the outside side wall of the tire 4 above the tire 4 bead and the rim 7. The tire 4 is not shown here and the chamber 1 is shown in an unloaded condition. There is a sharp angle α on the surfaces 10 comprising the wall of one of the points. The sharp angle will ensure the hermetical sealing of the walls forming the chamber 1 upon deformation of the chamber 1, while there is minimum bending and tension in the walls, which reduces the overall tension and material stress in the chamber 1 walls. The FIG. 3. b) shows a cross-section through the chamber 1 under load, the walls of the chamber 1 adjoin each other in the loaded point, the chamber 1 is blind and has the zero cross-section area of the chamber 1 in this point. The direction of deformation caused by load is indicated by a broken arrow.

[0062]The chamber 1 wi...

example 3

[0066]The chamber 1 can be manufactured by pressing in the matrix 9 between the walls of the chamber 1 and subsequent extraction of the matrix 9. The extension of the surfaces 10 outside the chamber 1 itself under the zero angle between the surfaces 10 then allows simple extraction of the matrix 9 in the manufacture of the chamber 1.

[0067]FIG. 3. d) shows the manufacture of the chamber 1 with a circular profile. The partly circular matrix 9 is impressed in the material of future chamber 1 walls; it is then extended outside the circular cross-section of the chamber 1 and led out of the ancillary structure 6. After pressing out, this extension will make parallel surfaces 10 passing through the chamber wall up to the point outside of the ancillary structure 6. Thus it will create a passage for extraction of the impressed matrix 9. Extraction of the matrix 9 is shown on FIG. 3e).

[0068]After fitting the ancillary structure 6 and tire 4 onto the rim 7, these extended surfaces 10 will pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com