Tyre forming drum with expansible centre and independent expansible tyre rim locking assembly in its end

A technology of tire building drum and bead locking, which is applied to tires, household appliances, and other household appliances. It can solve problems that affect the uniformity of tires and inaccurate assembly of components, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

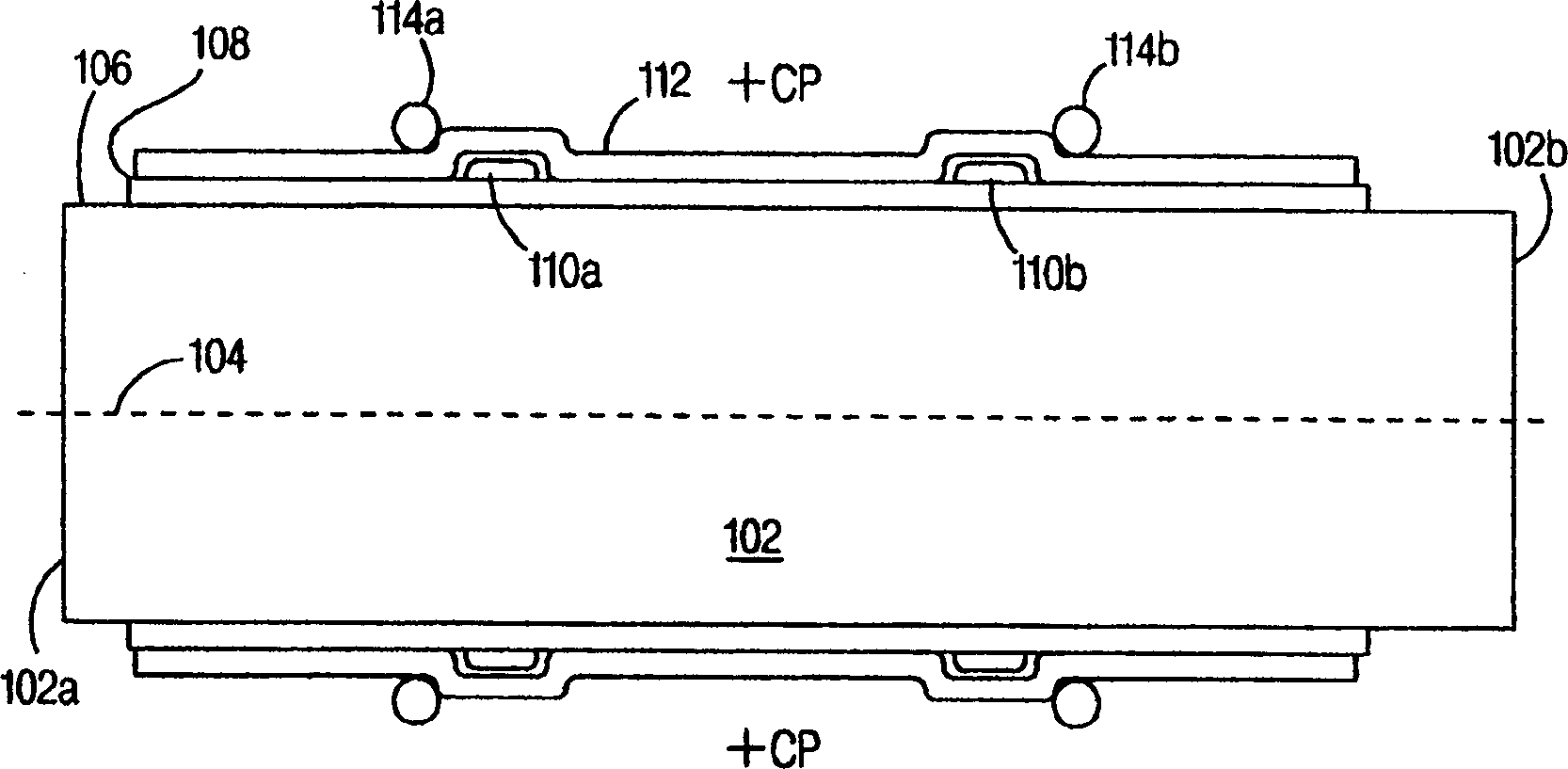

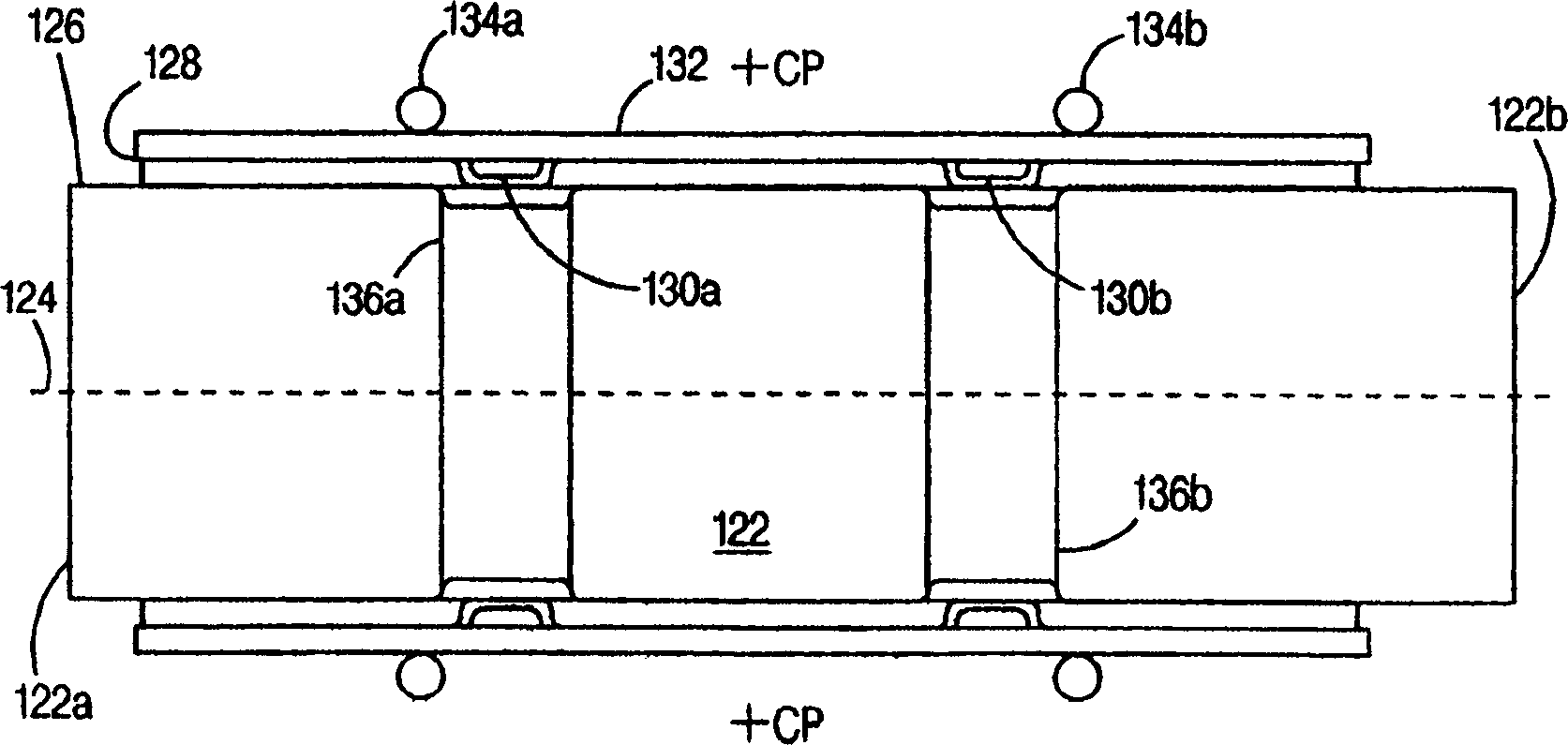

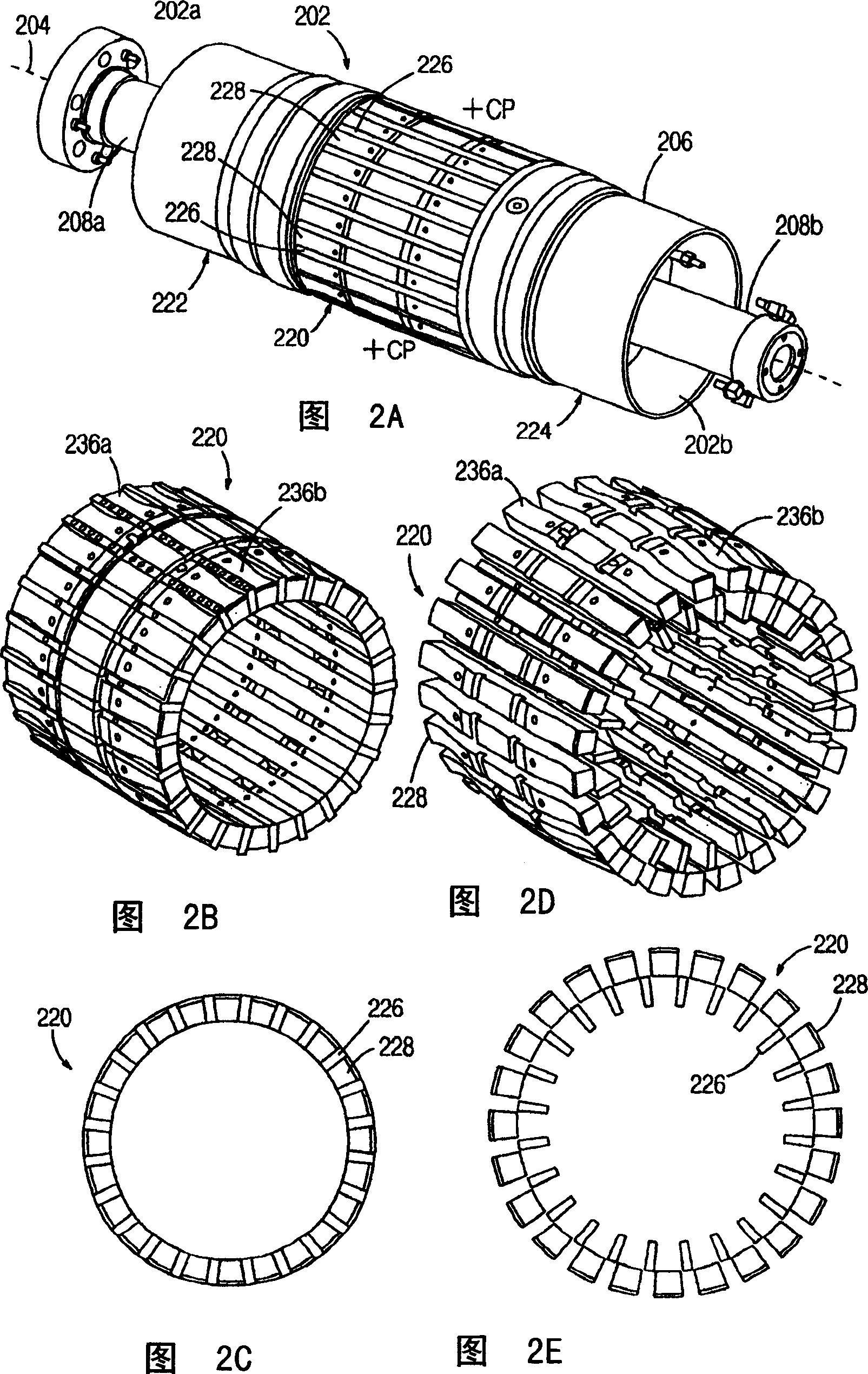

[0085] Generally speaking, the existing manufacturing process of radial automobile tires includes an intermediate step. This step is to install two ring-shaped tires on a tire building drum on other parts of the tire carcass. Expanded beads, each bead includes a steel wire rope encased in raw rubber. A ring-shaped rubber filler called "filler strip" with a triangular cross section can be added. Then the part of the ply component that extends beyond the bead is turned up around the bead to form the "turn-up end". Then, the green carcass is generally removed from the tire building drum and then installed on the "second stage machine" to inflate (reshape) into a ring shape, and its radial outer surface is pressed against a tread and belt assembly. In the subsequent steps, the green carcass is pressed together (rolled with a roller) to remove air bubbles and glue the inner surfaces together. The resulting component is inserted into a mold (pressurization press), heated (generally 350°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com