Inflatable tire

A technology for pneumatic tires and tires, applied to the reinforcement layer of pneumatic tires, tire parts, tire edges, etc., can solve problems such as unexpectable effects, achieve the effect of preventing wear and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

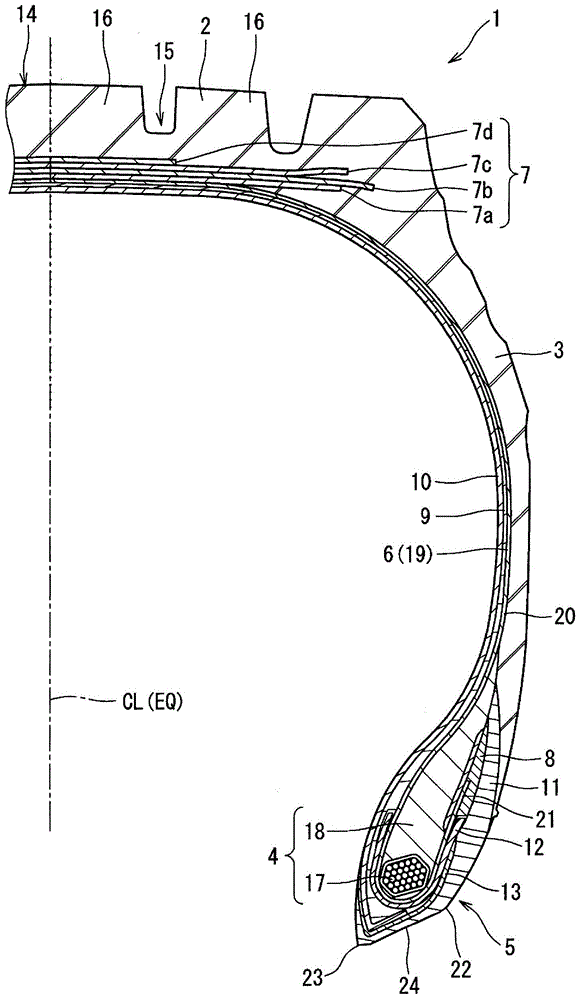

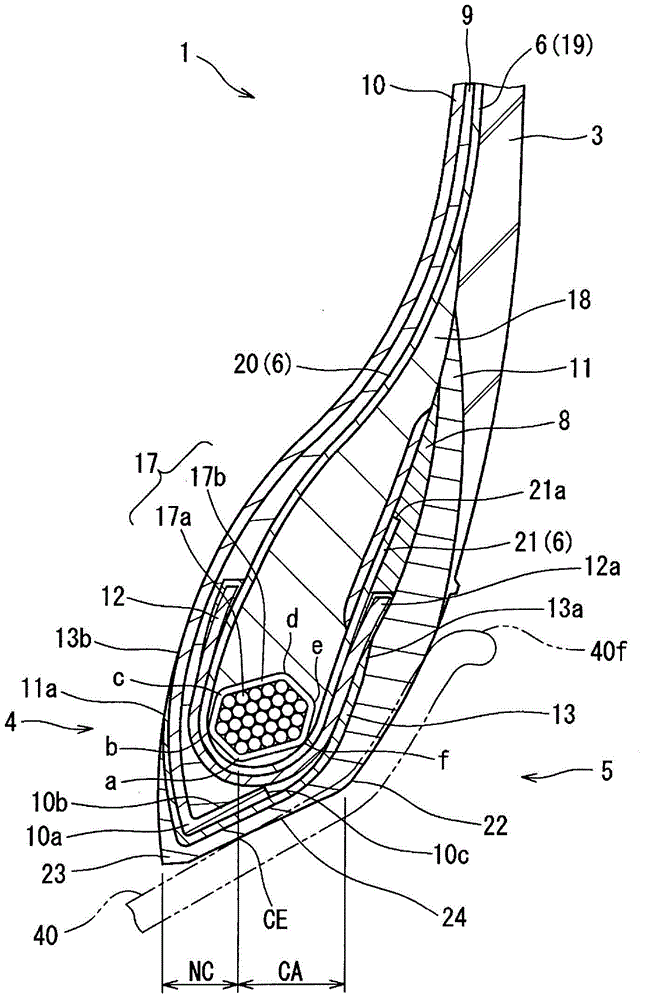

[0073] As Example 1, a figure 2 The shown heavy-duty pneumatic tire 1 has a U-shaped packing structure. The size of the tire 1 is 11R22.5. The rim on which this tire 1 is mounted is 7.50×22.5. This tire 1 has five ribs with a groove depth of 14.0 mm. As shown in Table 1, this tire 1 has a curved portion 10 b of an inner liner 10 with a rubber sheet 13 between the inner liner 10 and the chafer rubber 11 . The end portion 10c of the bent portion 10b is located axially outward from the radially innermost corner portion a of the bead core 17, that is, axially outward from the fitting end CE. Table 1 shows the thickness of the inner liner 10 and the composition ratio, physical properties and thickness of the rubber sheet. In order to evaluate the performance of the tire 1 of Example 1, the above-mentioned water-filled bench test and no-water bench test were carried out. Table 1 shows the test results (evaluation results) for this tire 1 .

Embodiment 2~10

[0075] As Examples 2-10, produced figure 2 The shown heavy-duty pneumatic tire 1 has a U-shaped packing structure. Various specifications of the inner liner 10 of the tire 1 and various specifications of the rubber sheet 13 are shown in Tables 1 and 2. Other configurations and test conditions of the above-mentioned tire 1 are the same as those of the above-mentioned Example 1. Table 1 and Table 2 show the test results (evaluation results) for the tire 1 described above.

Embodiment 11

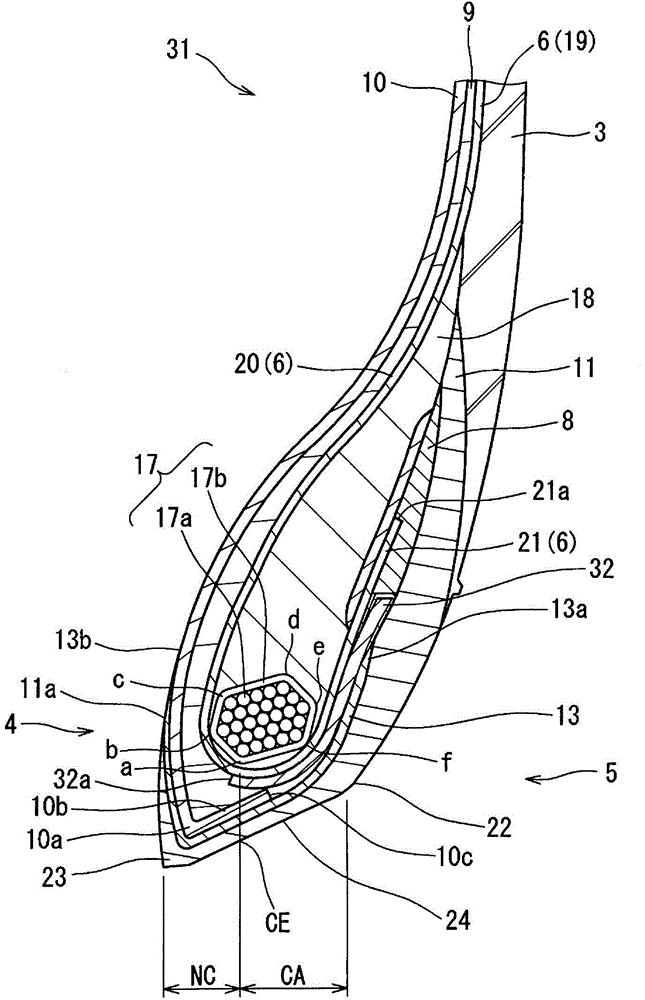

[0077] As Example 11, produced Figure 4 The shown heavy-duty pneumatic tire 35 has a U-shaped packing structure. This tire 35 does not have the rubber sheet 13 . Various specifications of the inner liner 10 of the tire 35 are shown in Table 2. The other structures and test conditions of this tire 35 are the same as those of the above-mentioned Example 1. Table 2 shows the test results (evaluation results) for this tire 35 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com