Method for producing electronic product, and electronic product

A technology of electronic components and manufacturing methods, which is applied in the fields of fixed capacitor parts, transformer/inductor parts, inductance/transformer/magnet manufacturing, etc., and can solve the problem of residue, plating solution immersion in the ceramic element body and internal electrodes. Boundaries, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example -

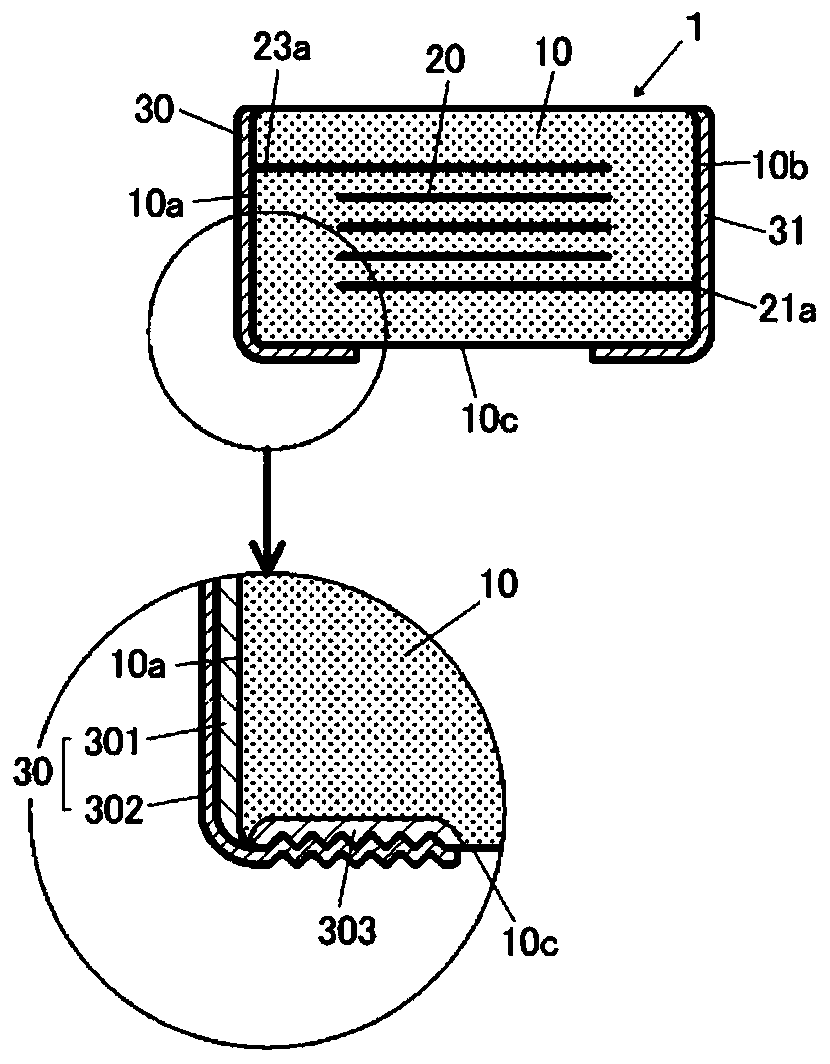

[0053] Hereinafter, an experimental example in which a reformed portion and a plating electrode were formed will be described.

[0054] (1) A sintered ceramic element body made of Ni-Cu-Zn-based ferrite is irradiated while scanning repeatedly with laser light. Although the processing conditions are as follows, the wavelength may be in any range from 532 nm to 10620 nm, for example. The irradiation interval refers to the distance between the forward path and the point center of the return path when scanning the laser light repeatedly.

[0055] [Table 1]

[0056] [Laser processing conditions]

[0057] wavelength

1064nm (YVO4)

Output Power

14A

scanning speed

200mm / s

Q switch frequency

20kHz

Irradiation interval (pitch)

30μm

Spot diameter

70μm

1J / sec

[0058] (2) The ceramic element body after laser irradiation was plated under the following conditions. Specifically, barrel platin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com