Sintered colored pencil lead

A pencil lead, color technology, applied in pencil lead, non-moving pencil, printing, etc., can solve the problem of low erasability of handwriting, and achieve the effect of excellent erasability and smooth writing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

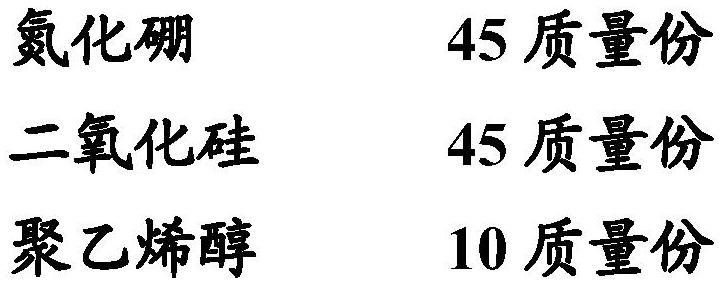

[0130] [Kneading process, extrusion process, and firing process]

[0131]

[0132]

[0133] The above complex was evaporated with a kneader and three rolls, heated and kneaded, and the obtained kneaded product was extruded into a predetermined diameter to obtain a linear molded product. The linear molded product was heated up to 600°C at a temperature increase rate of 10°C / hour in argon gas, and kept for 5 hours, then heated at 100°C / hr in an oxygen atmosphere, and fired at 900°C for 1 hour. A porous substrate having a porosity of 25% and a cross-sectional diameter of 0.55 mm was obtained.

[0134] [Impregnation process]

[0135] 70 parts by mass of ethanol

[0136] 30 parts by mass of yellow common dye

[0137] (Salt-forming dye of basic dye and organic acid, manufactured by Hodogaya Chemical Industry Co., Ltd., trade name: AizenSpilon Yellow C-GNH)

[0138] The above complex was stirred at 60°C until uniformly mixed to obtain a colorant solution (1).

[0139]The p...

Embodiment 2~17

[0146] Colored pencil leads were obtained in the same manner as in Example 1 except that the colorant solution (1) or the low-volatile liquid (1) was changed to the liquids described in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com