Structure having liquid layer on surface

A structure and liquid layer technology, applied in the field of structures, can solve the problems of disappearance of surface characteristics, and achieve the effect of long-term display of surface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

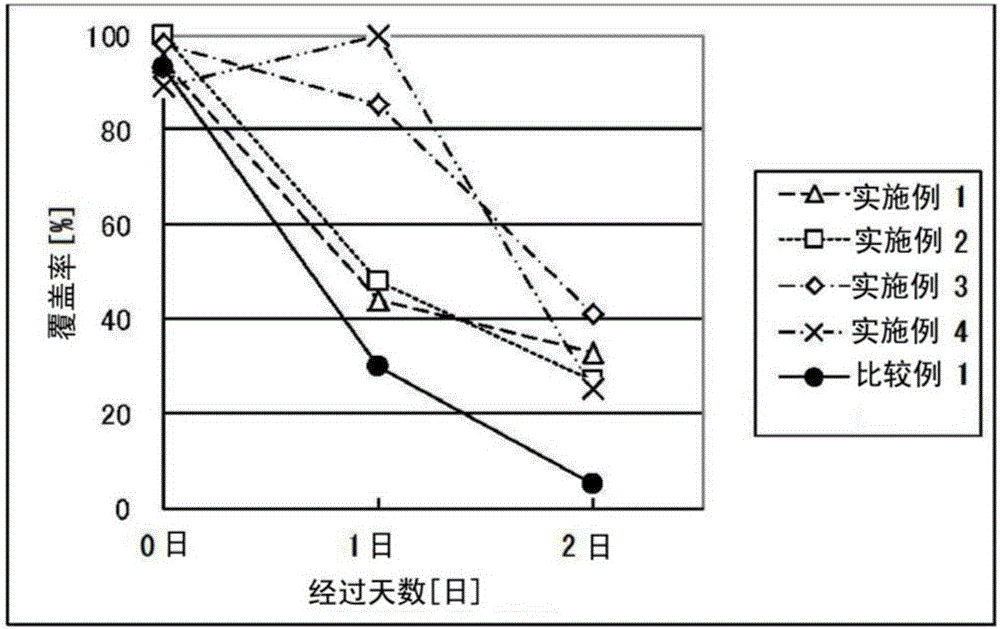

[0099] As the base resin, low-density polyethylene (LDPE) having a glass transition point (Tg) of -120°C was provided.

[0100] As fine particles for filling the amorphous portion, further, silica fine particles having a mesh particle size of 20 μm or less and an average particle size (measured by a laser diffraction light scattering method) of 10 μm or less are provided .

[0101] LDPE was fed to extruder A and a resin composition of LDPE / silica fine particles=99 / 1 (weight ratio) was fed to extruder B by using a Laboplusto-mill. These resins were extruded through an annular die maintained at a temperature of 210° C. to prepare a cylinder comprising LDPE on the inner side and a fine particle-blended resin (LDPE / silica fine particle resin composition) on the outer side shaped two-layer film. The film thickness was measured by using a microscope; that is, the LDPE layer on the inner side was about 60 μm thick, the fine particle-blended resin layer on the outer side was about 7...

Embodiment 2

[0104] A film was produced in the same manner as in Example 1 except that the weight ratio of LDPE / silica fine particles was set to 97 / 3. The film is coated with liquid and its liquid coverage is measured. The results are shown in Table 1.

Embodiment 3

[0106] A film was prepared in the same manner as in Example 1 except that the weight ratio of LDPE / silica fine particles was set to 95 / 5. The film is coated with liquid and its liquid coverage is measured. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com