Substrate processing method and substrate processing apparatus

A substrate processing method and substrate technology are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., to achieve the effects of suppressing collapse and suppressing changes in the line width of patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

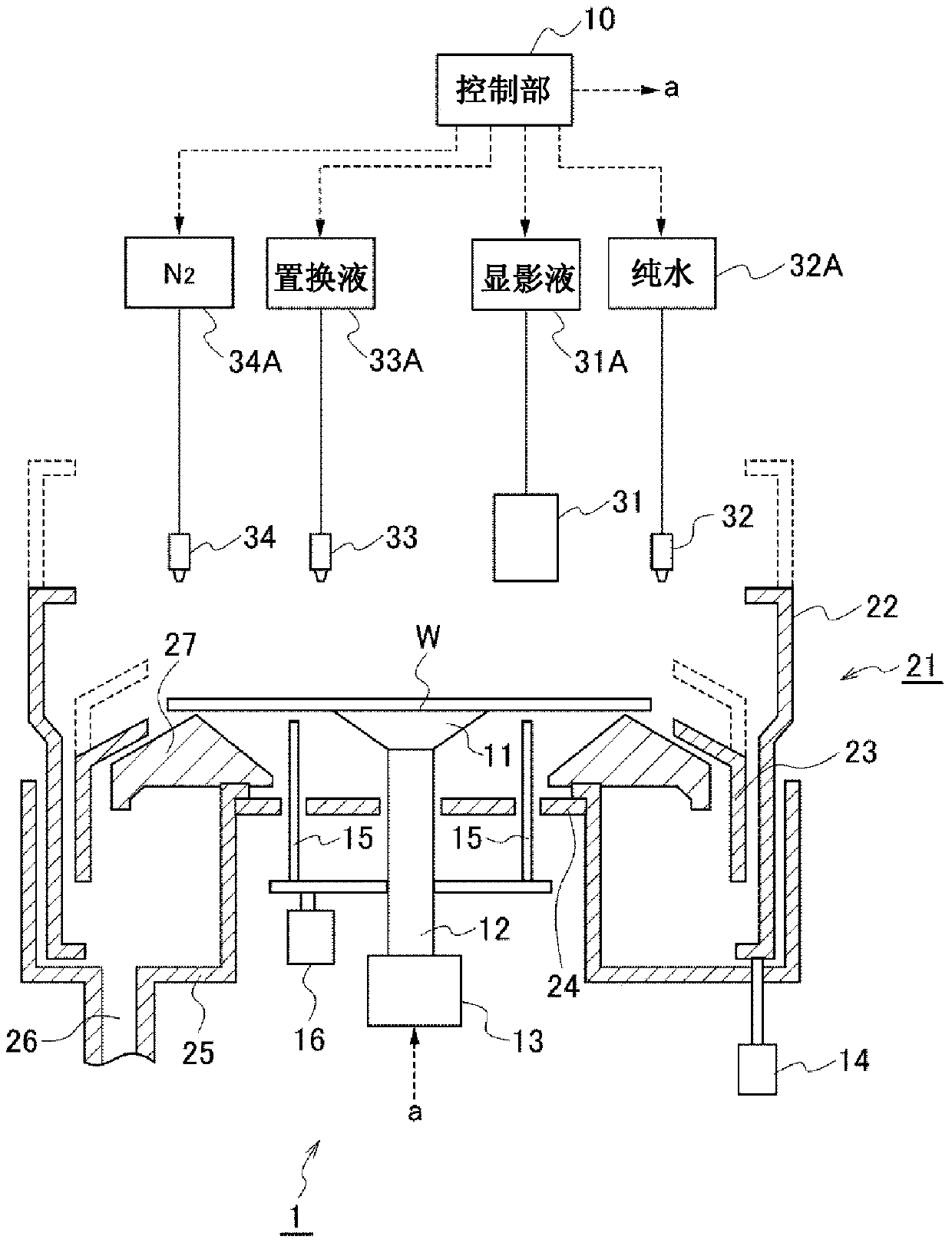

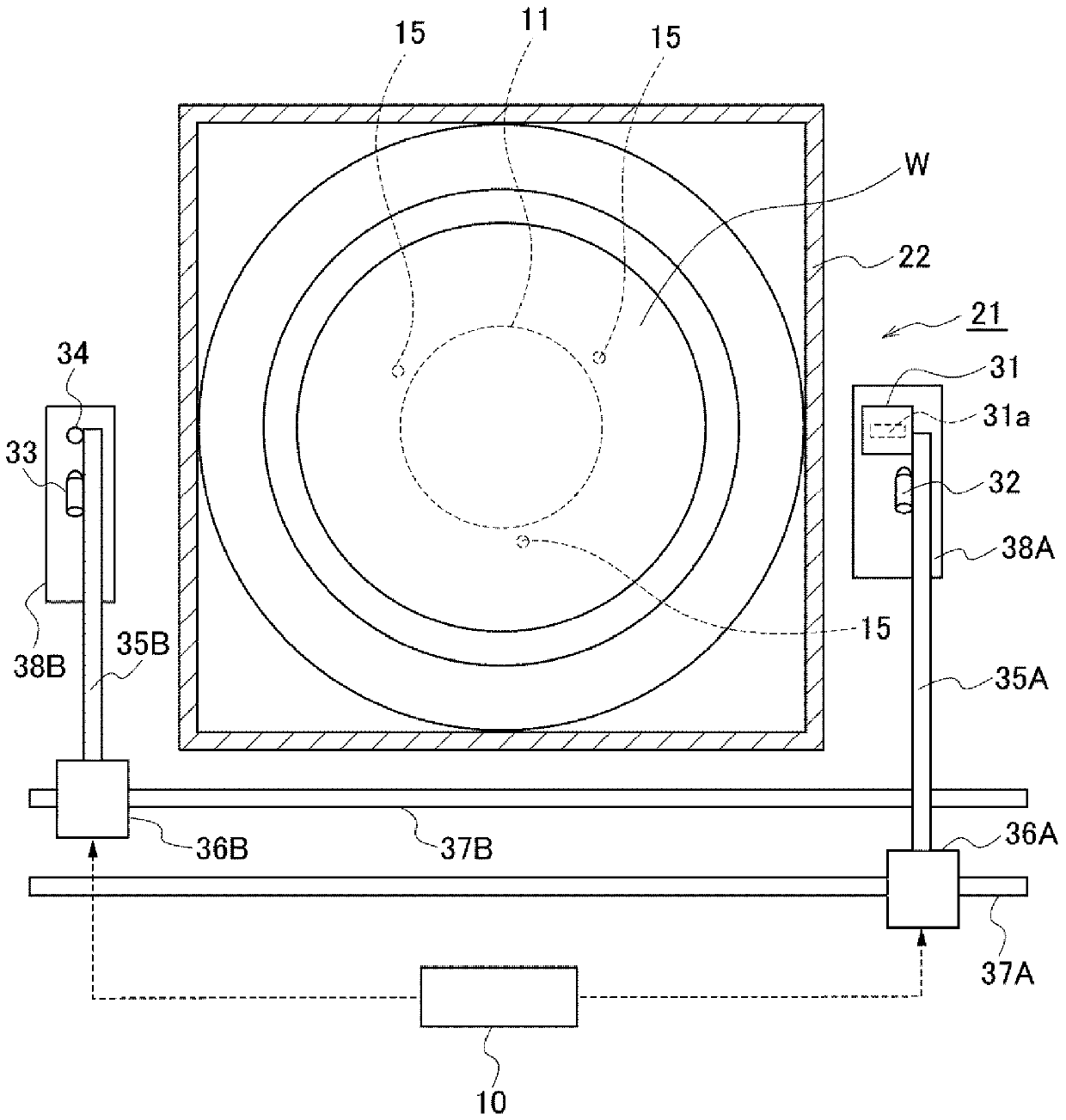

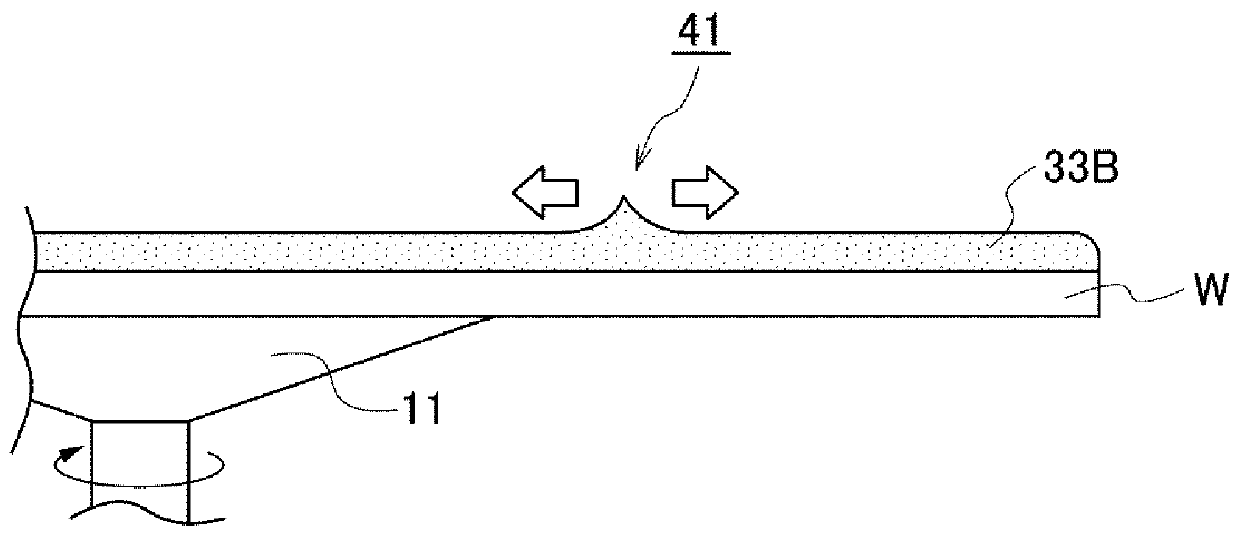

[0077] refer to figure 1 longitudinal section side view of and figure 2 The plan view of FIG. 1 illustrates the developing device 1 constituting the substrate processing apparatus of the present invention. In the developing device 1 , the wafer W is transported by a substrate transport mechanism not shown. A resist film is formed on the surface of the wafer W, and the resist film is exposed in a predetermined pattern.

[0078] In the figure, 11 is a spin chuck, which is a substrate holding part for suctioning and attaching the central part of the back side of the wafer W to maintain a horizontal posture. The spin chuck 11 is connected to the rotation mechanism 13 via the rotation shaft 12, and the wafer W can be freely rotated while holding the wafer W. A cup body 21 with an upper side opening is provided such that the cup body 21 surrounds the wafer W on the spin chuck 11 . The cup body 21 includes, for example, an outer cup 22 whose upper side is quadrangular and whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com