Container for optical stereoscopic shaping device

A container and irradiation device technology, which is applied to household containers, chemical instruments and methods, and accessories for processing main materials, etc., can solve problems such as deterioration, shape deformation, and damage to containers, and achieve excellent durability and molding accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

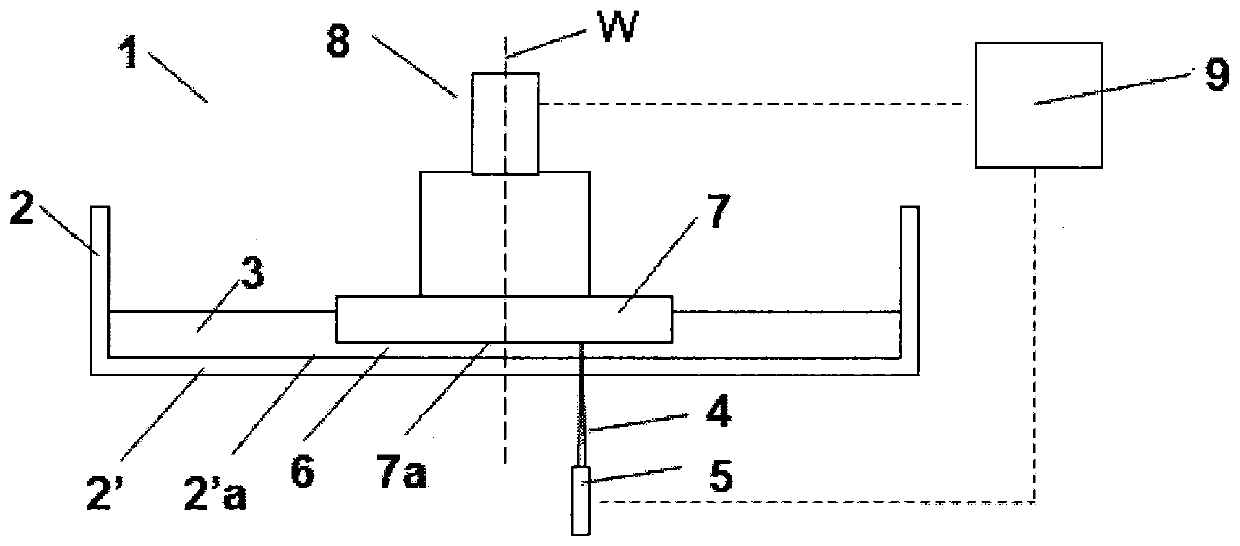

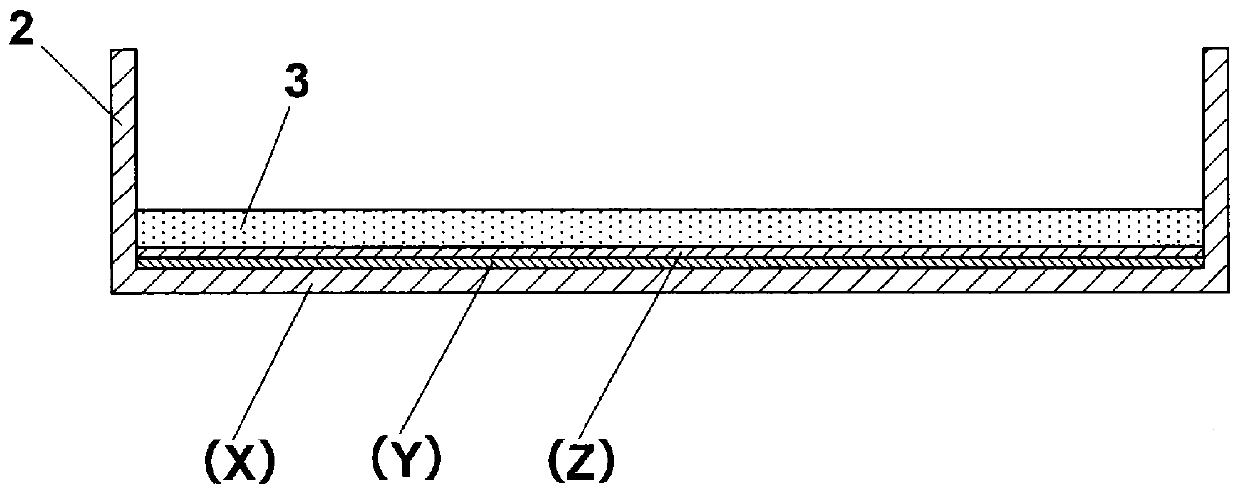

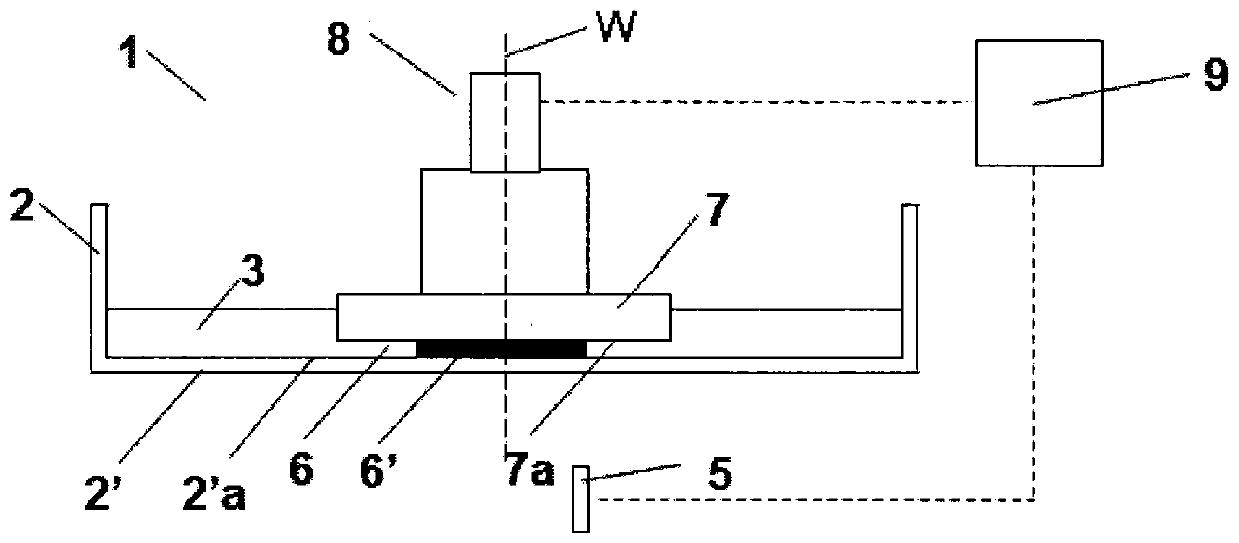

[0076] A prism made of PMMA with a thickness of 12 mm x width of 30 mm, and a sheet made of PMMA with a thickness of 1.0 mm x 1 side of 244 mm (pencil hardness measured according to JIS K 5600-5-4: 1999 is 3H), and produced a height of 33 mm x 1 side 244mm, bottom thickness 1.0mm, bottom area 484cm 2 of PMMA containers.

[0077] Next, 100 g of KE-103 and 5.0 g of CAT-103 were collected in a disposable cup made of polypropylene, and stirred by hand for about 1 minute using a spatula to obtain Silicone 1. 25 g of the above-mentioned silicone 1 was poured into the above-mentioned container made of PMMA, the whole was spread with a spatula, and after standing for 24 hours, the temperature was raised at 70° C. for 6 hours to form a soft resin layer. The hardness of the soft resin layer measured by JIS K 6253-3:2012 Type A durometer (Aska Rubber Hardness Tester Type A, manufactured by Macromolecular Keiki Co., Ltd.) was 50, and the thickness of the soft resin layer was 0.5 mm.

[...

Embodiment 2

[0080] Except for changing the thickness of the PMMA-made sheet, that is, the thickness of the first layer (X), changing the amount of the silicone 1 flowing into the PMMA-made container to 250 g, and changing the thickness of the FEP sheet to 0.5 mm Otherwise, in the same manner as in Example 1, a container was produced. The hardness of the soft resin layer measured by the JIS K 6253-3:2012 type A durometer was 50, and the thickness of the soft resin layer was 5.0 mm.

Embodiment 3

[0082] PMMA was changed to PC (the pencil hardness of the sheet made of PC measured according to JIS K 5600-5-4:1999 was F), the thickness of the first layer (X) was changed to 3.0 mm, and the silicone 1 was changed For silicone 2, the amount of silicone 2 flowing into the PC-made container was changed to 50 g, and the FEP sheet with a thickness of 0.25 mm was changed into an ETFE sheet with a thickness of 0.75 mm, in the same manner as in Example 1. Make the container in the same way. The hardness of the soft resin layer measured by the JIS K 6253-3:2012 type A durometer was 60, and the thickness of the soft resin layer was 1.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com