Whole process dynamic monitoring method for converter steel melting

A dynamic monitoring and converter steelmaking technology, which is applied in the field of metallurgical steelmaking, can solve the problems that the sub-lance method is not suitable for small and medium converters, and is not a full-range dynamic control, etc., and achieve the effect of improving the level of smelting control, simple installation method, and simple and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

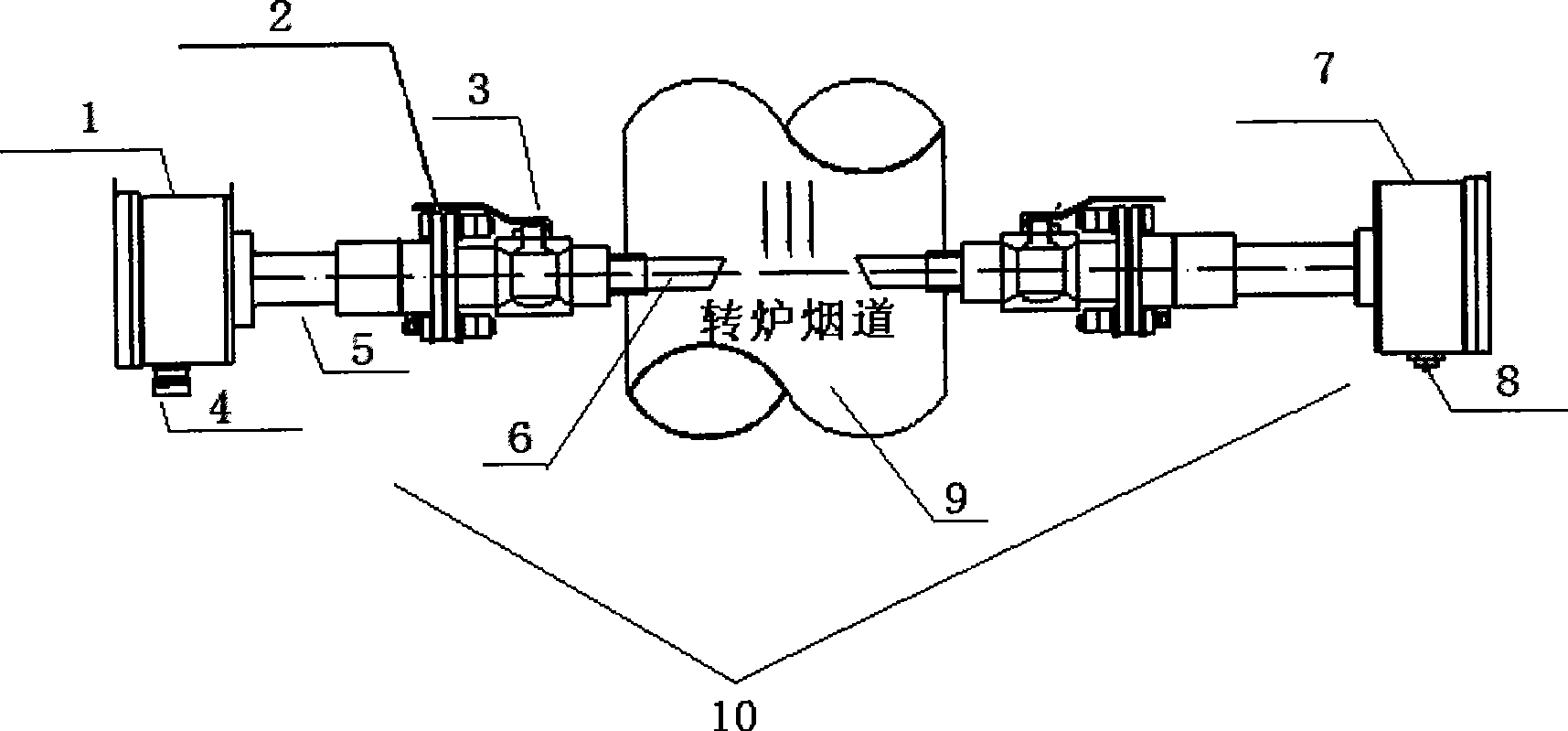

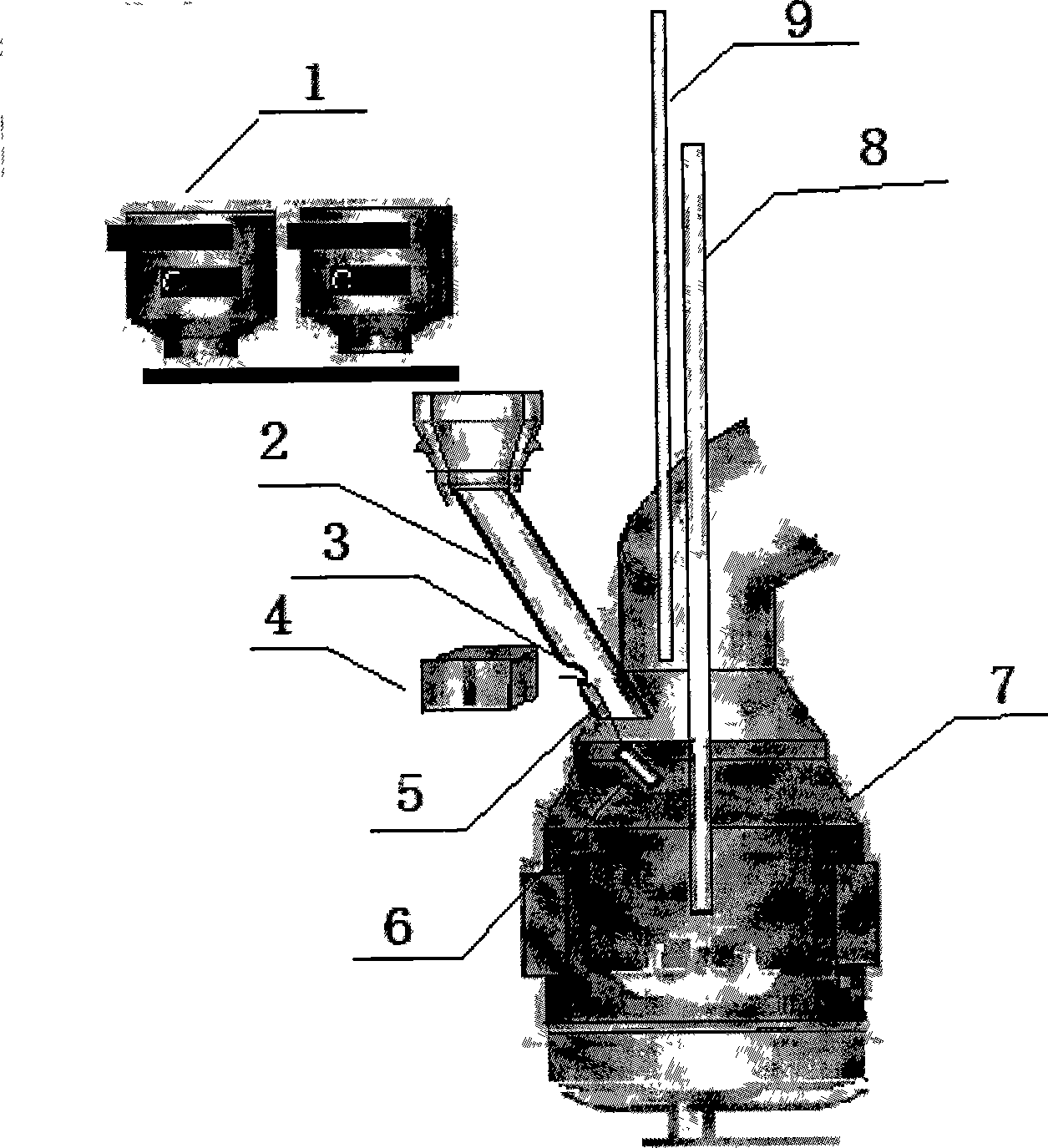

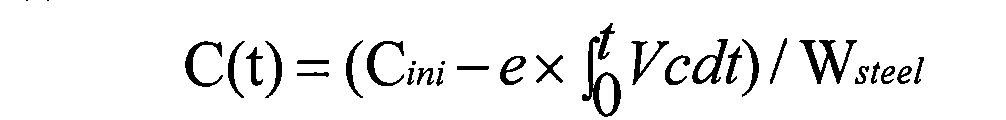

Method used

Image

Examples

Embodiment 1

[0052] 120t converter steelmaking production, furnace number 80708562, steelmaking raw materials: 100t molten iron, 5t scrap steel, 10t iron nuggets. Smelting steel Q345B. During the smelting process, the furnace gas composition is analyzed throughout the whole process, and the blowing is automatically bombed and corrected at the 903rd second. At the end of the blowing, the system predicts that the carbon content of the molten steel at the end of the system is 0.029%, and the temperature is 1606°C; double samples are taken from the furnace to measure the double temperature comparison The test results are: the carbon content of sample 1 is 0.04%, the carbon content of sample 2 is 0.04%, and the average value is 0.040%; the temperature one is 1611°C, the temperature two is 1598°C, and the average value is 1604.5°C. Therefore, the carbon content error is 0.011%, and the temperature error is 1.5°C.

Embodiment 2

[0054] 120t converter steelmaking production, furnace number 80708564, steelmaking raw materials: 102t molten iron, 5t scrap steel, 8t iron nuggets. Smelting steel Q345B. During the smelting process, the furnace gas composition analysis is carried out throughout the whole process, and the blowing is automatically bombed and corrected at the 923rd second. At the end of the blowing, the system predicts that the carbon content of the molten steel at the end point is 0.038%, and the temperature is 1692°C; double samples are taken from the furnace to measure the double temperature comparison The test results are: the carbon content of sample 1 is 0.039%, the carbon content of sample 2 is 0.039%, and the average value is 0.039%; the temperature one is 1694°C, the temperature two is 1695°C, and the average value is 1694.5°C. Therefore, the carbon content error is 0.001%, and the temperature error is 2.5°C.

Embodiment 3

[0056] 120t converter steelmaking production, furnace number 80708565, steelmaking raw materials: 103t molten iron, 4t scrap steel, 8t iron nuggets. Smelting steel SPHC. During the smelting process, the furnace gas composition analysis is carried out throughout the whole process, and the blowing is automatically bombed and corrected at the 913th second. At the end of the blowing, the system predicts that the carbon content of the molten steel at the end point is 0.04%, and the temperature is 1654°C; double samples are taken from the furnace for double temperature comparison The test results are: the carbon content of sample 1 is 0.031%, the carbon content of sample 2 is 0.037%, and the average value is 0.034%; the temperature one is 1647°C, the temperature two is 1642°C, and the average value is 1644.5°C. Therefore, the carbon content error is 0.006%, and the temperature error is 9.5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com