Patents

Literature

37results about How to "Reliable optimization results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexagonal circularly polarized antenna array and rapid optimization method thereof

ActiveCN108829988ANo human intervention requiredReliable optimization resultsDesign optimisation/simulationSpecial data processing applicationsCircularly polarized antennaElement model

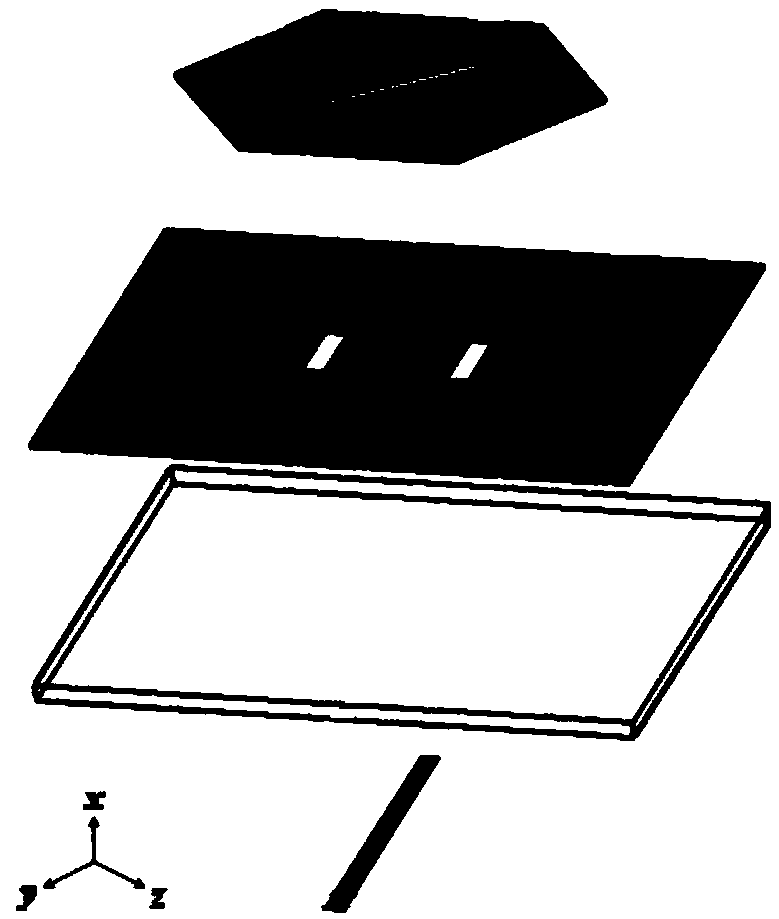

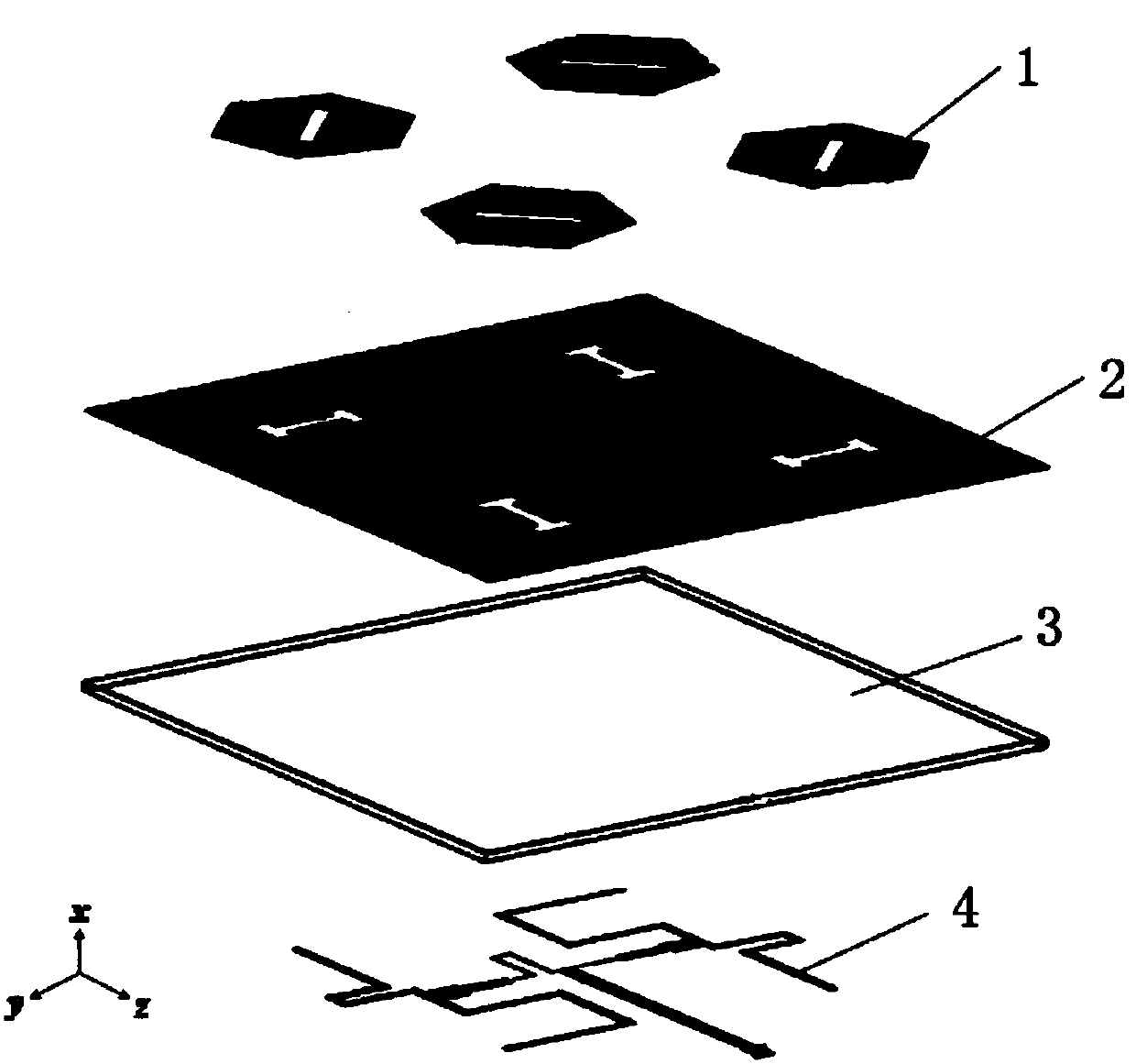

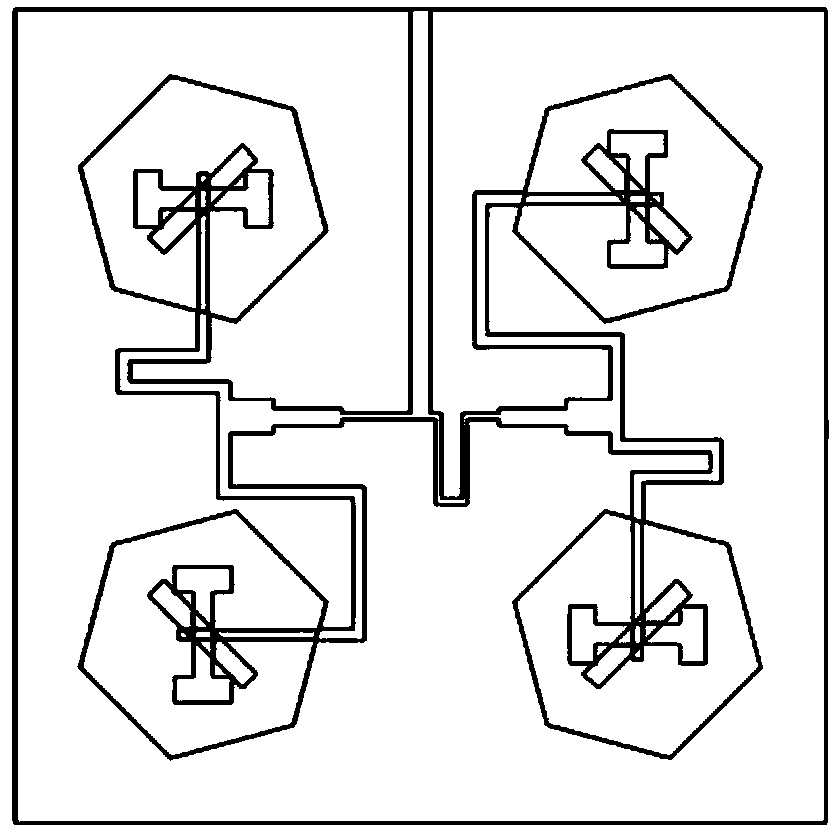

The invention relates to a hexagonal circularly polarized antenna array and a rapid optimization method thereof. The hexagonal circularly polarized antenna array comprises an FR4 medium substrate, a feed network, a reflective face and a hexagonal radiation patch. The rapid optimization method of the hexagonal circularly polarized antenna array includes the following steps that 1, a finite elementmode of a unit antenna to be optimized is established; 2, the design variable of the unit antenna to be optimized is determined; 3, a parallel lower confidence limit optimization algorithm is called to optimize the finite element model of the initial unit antenna; 4, an optimizing result Y= (y1, y2,..., yn) T, and an optimal design scheme Yopt is analyzed and utilized for arraying, so that a finite element model of an initial array to be optimized is obtained; 5, the design variable of the finite element model of the initial array to be optimized is determined and serves as the initial samplepoint of the parallel lower confidence limit algorithm; 6, the parallel lower confidence limit algorithm is called to optimize the initial array to be optimized; 7, the optimization result of the antenna array is obtained.

Owner:XIDIAN UNIV

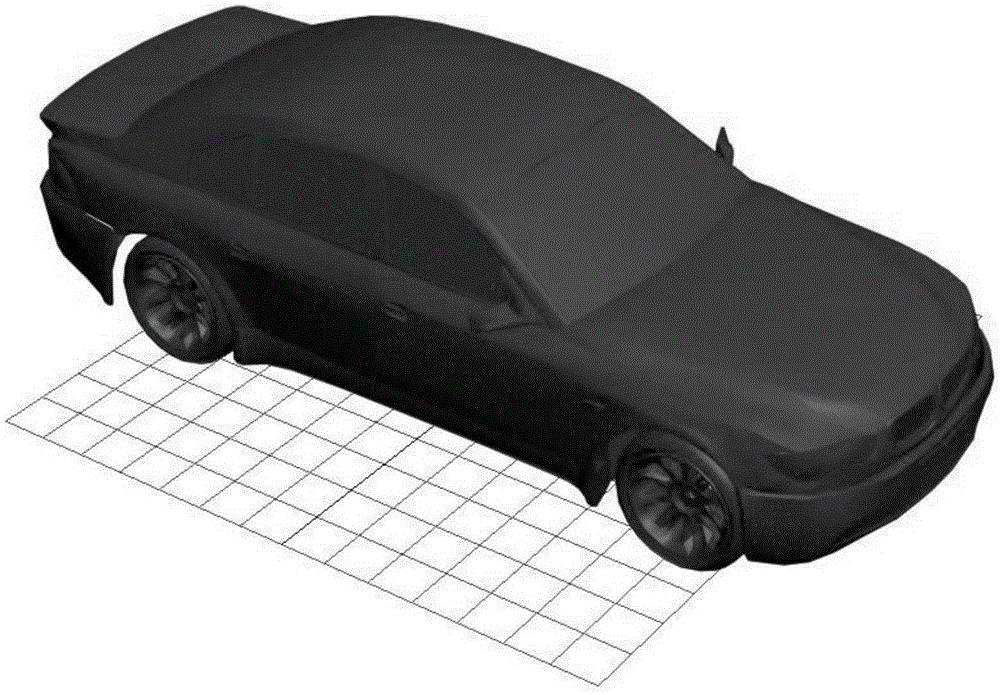

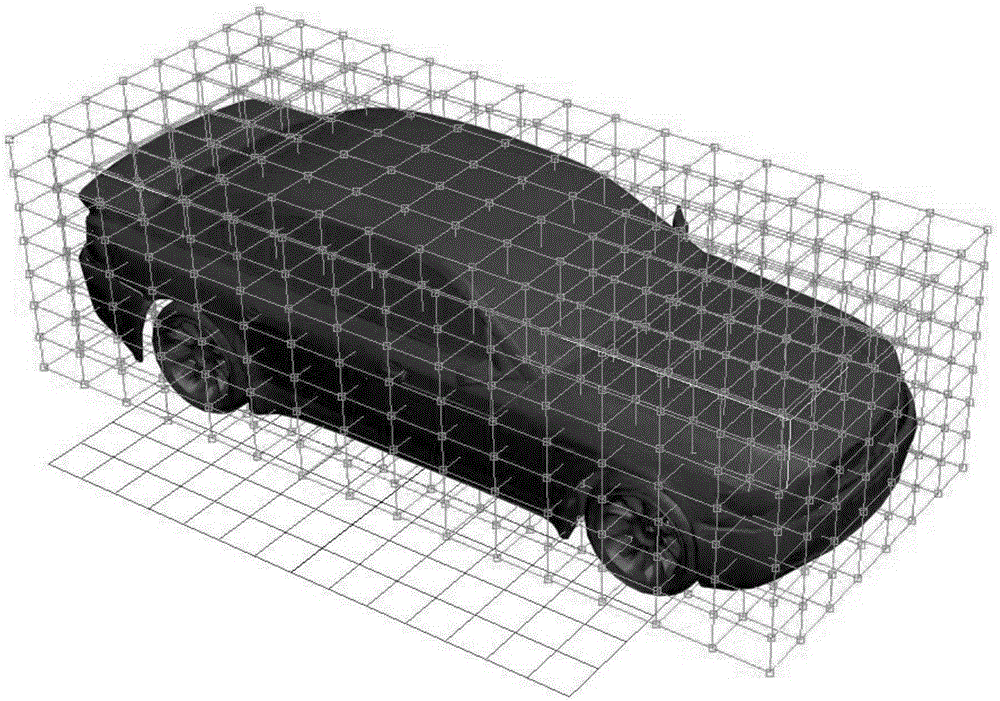

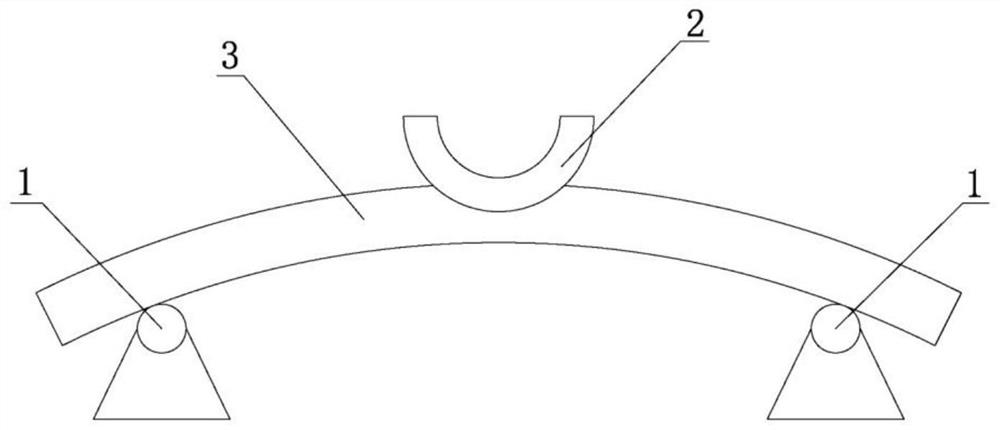

Car body aerodynamic modeling optimization method based on free deformation technology

InactiveCN105243243AShorten the development cycleEasy to controlSpecial data processing applicationsModel sampleAerodynamic drag

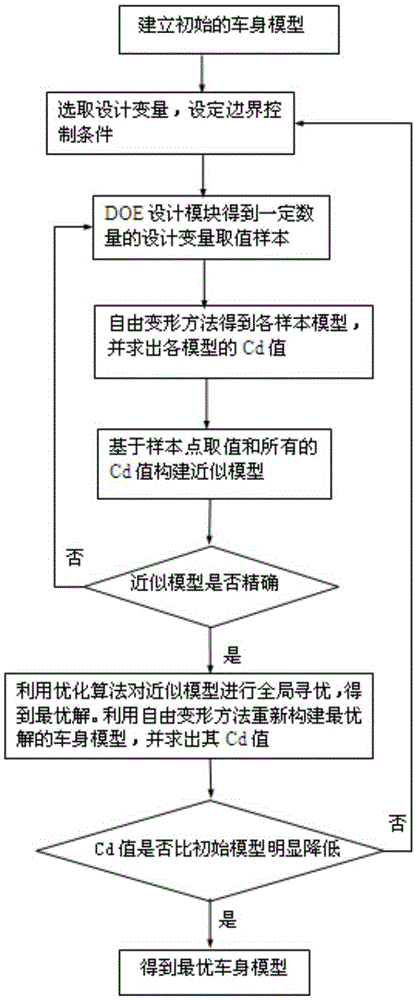

The invention discloses a car body aerodynamic modeling optimization method based on free deformation technology, comprising the following steps: firstly, constructing a simplified car body model, wherein points needing deformation control on the car body model is taken as design variables, setting boundary control conditions for the design variables, and obtaining a certain number of car body model samples according to the boundary control conditions; obtaining the car body model of the schemes by utilizing a free deformation method and solving the corresponding Cd value; then constructing an approximate model, solving the optimal solution of the approximate model by utilizing an optimization algorithm, re-constructing the car body model according to the position of a control point with optimal solution and obtaining the air resistance coefficient Cd value, comparing the air resistance coefficient Cd value with the Cd value of a simplified original model, and if the value is not reduced, returning to S2 to modify the boundary conditions or re-select the design variables to continue the procedure. By utilizing the optimization method disclosed by the invention, car body optimization is easy to control, and in certain boundary conditions, the optimization result is relatively reliable.

Owner:WUHAN UNIV OF TECH

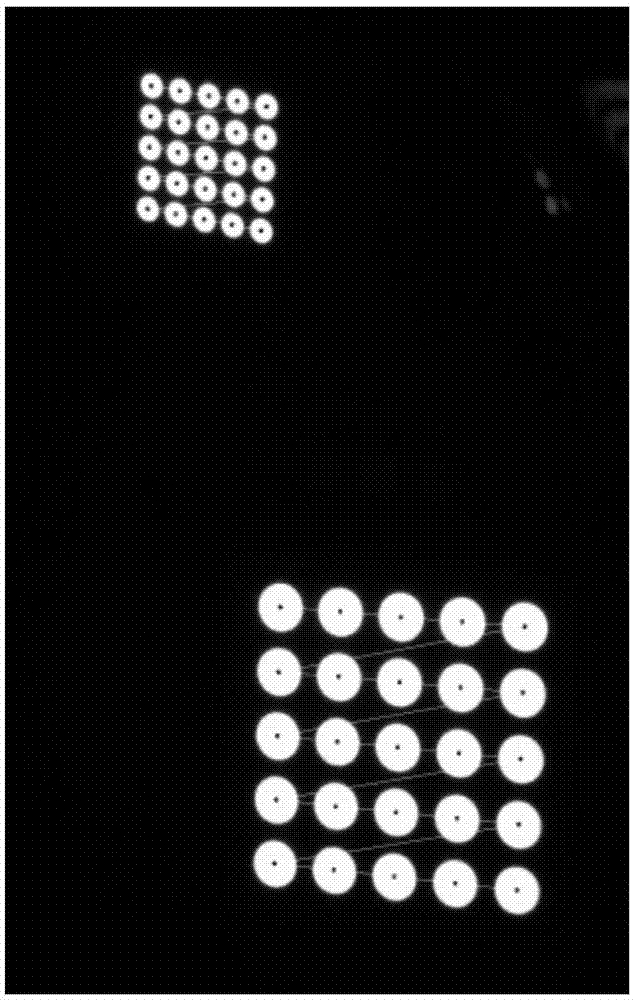

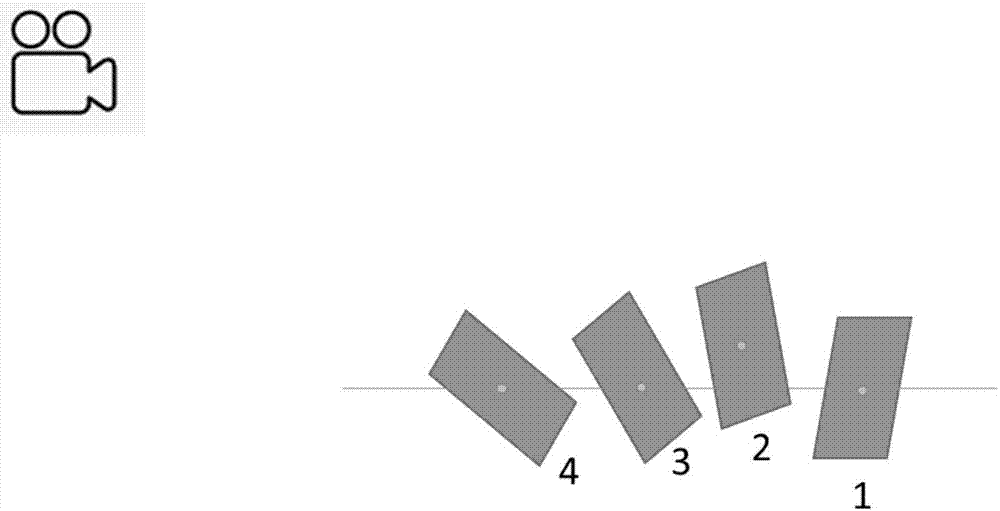

Spatial position and posture solving method based on integral target optimization

ActiveCN107576286AReasonable and accurate spatial postureConducive to solutionUsing optical meansBack calculationBack projection

The invention discloses a spatial position and posture solving method based on integral target optimization, and belongs to the field of production, maintenance and service of vehicles. According to the spatial position and posture solving method based on integral target optimization, imaging of targets in different states can be taken as imaging of a same target on cameras, the cameras in different states can be used for shooting the targets at different spatial positions, known spatial points are projected into the cameras for imaging according to the related principle of three-dimensional reconstruction, constraint is done based on minimum back projection, least square solving is performed to acquire the positions of the cameras, the cameras (corresponding to large target extraction errors caused by factors such as shaking during movement) with large residual errors are eliminated, and accurate postures and positions of the targets are acquired through back calculation.

Owner:安徽省爱夫卡电子科技有限公司

Hydrofracture design parameter optimization method based on fine classification of reservoir

ActiveCN105003240AReliable optimization resultsRealisticFluid removalHydraulic fracturingEngineering

Owner:SOUTHWEST PETROLEUM UNIV +1

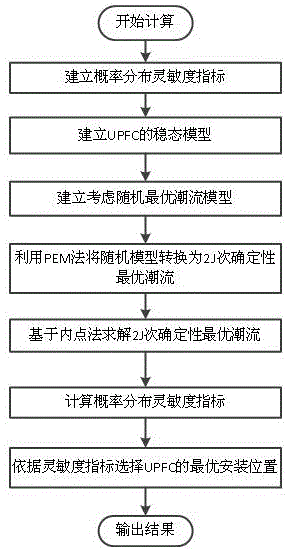

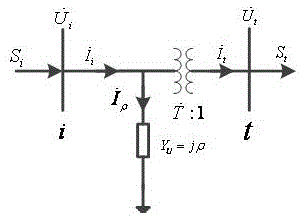

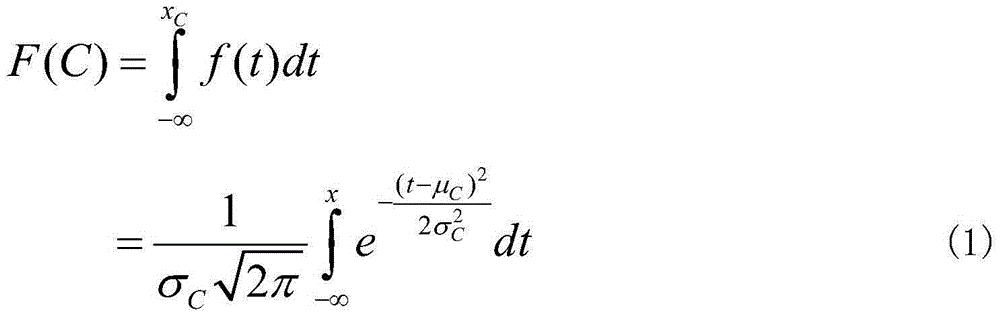

UPFC (Unified Power Flow Controller) installation position optimization method considering load and new energy randomness

ActiveCN105117983ASafe and stable operationImprove economyData processing applicationsSystems intergating technologiesElectricityInterior point method

The invention discloses a UPFC (Unified Power Flow Controller) installation position optimization method considering load and new energy randomness. The UPFC installation position optimization method comprises the following steps: firstly, deducing an expression of power grid operation cost on a probability distribution sensitivity index of a control variable of a UPFC; then, establishing a UPFC-contained random optimal tidal current model which considers load, wind power and photovoltaic random variables; on the basis of an interior point method and a point estimation algorithm, realizing the calculation of the probability distribution sensitivity index; and on the basis of the sensitivity, selecting an optimal installation position of the UPFC. The UPFC installation position optimization method considering the load and new energy randomness has the meaning that the influence of the UPFC on the change of the probability distribution of power grid operation cost on different lines can be visually reflected, and the optimal installation potion of the UPFC is determined on the basis of the index. The method provides a new thought for fully performing the function of the UPFC on the safe and stable operation of the power grid and improving power grid economy.

Owner:STATE GRID CORP OF CHINA +2

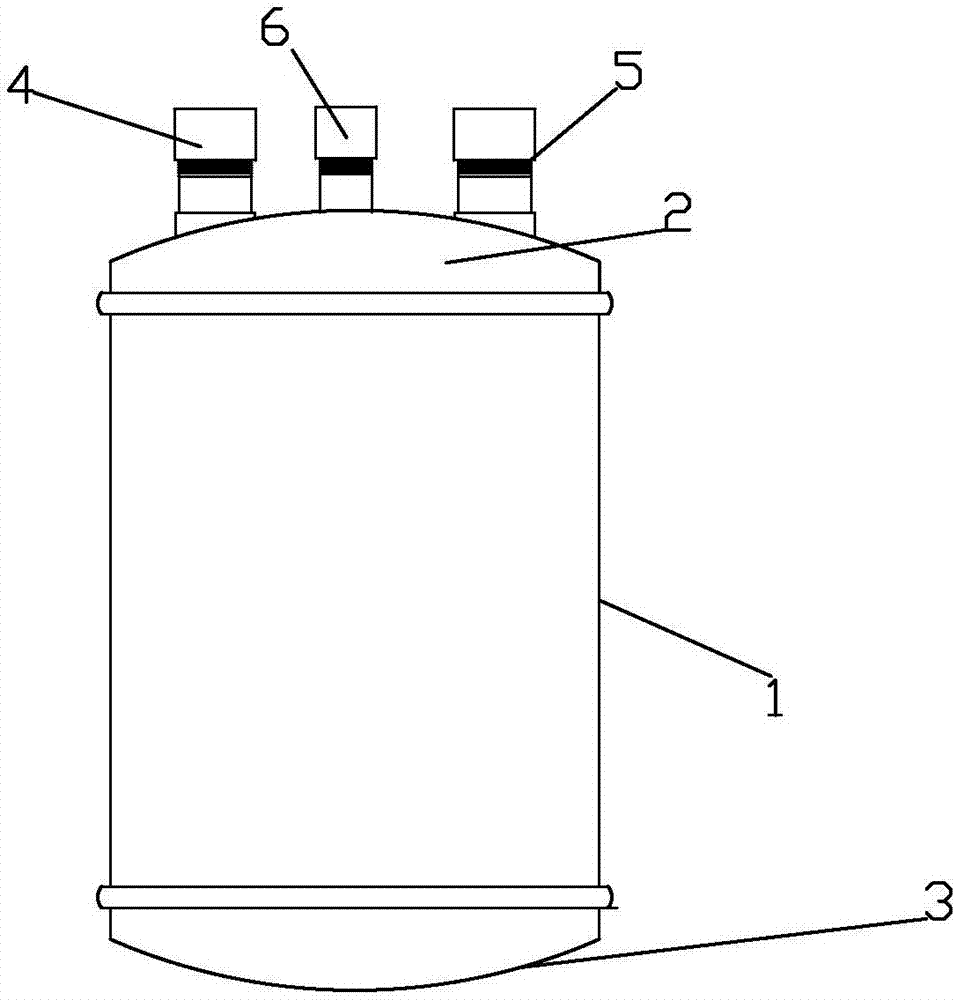

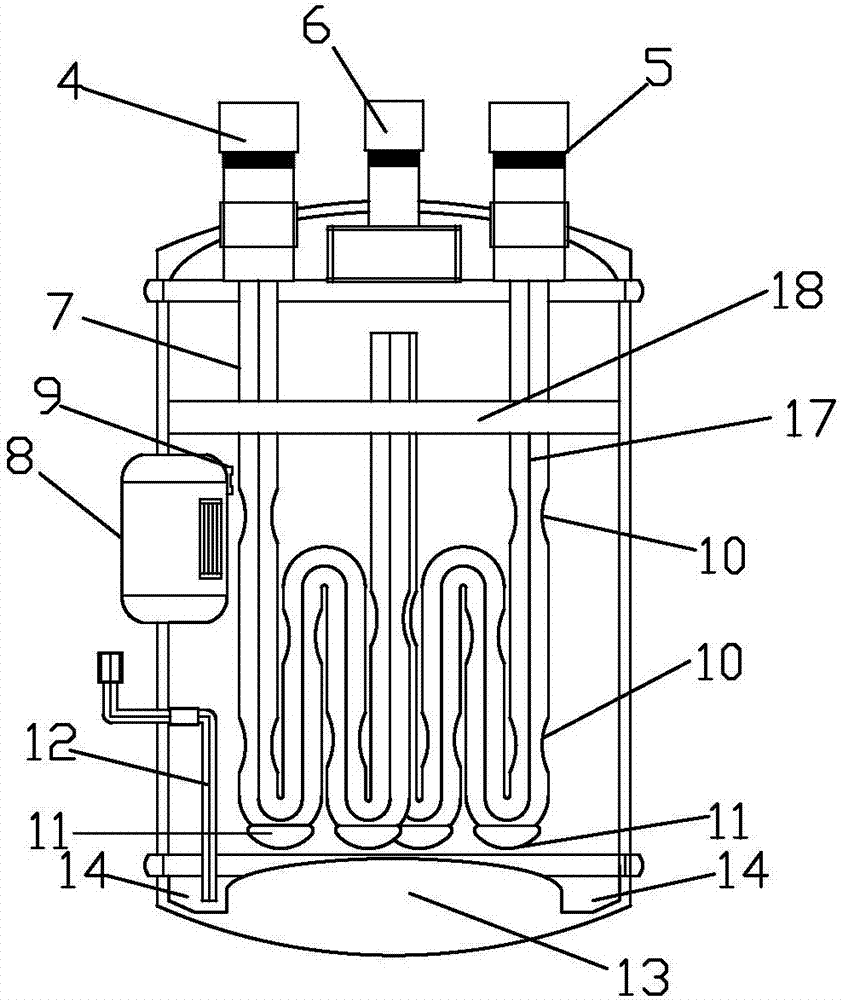

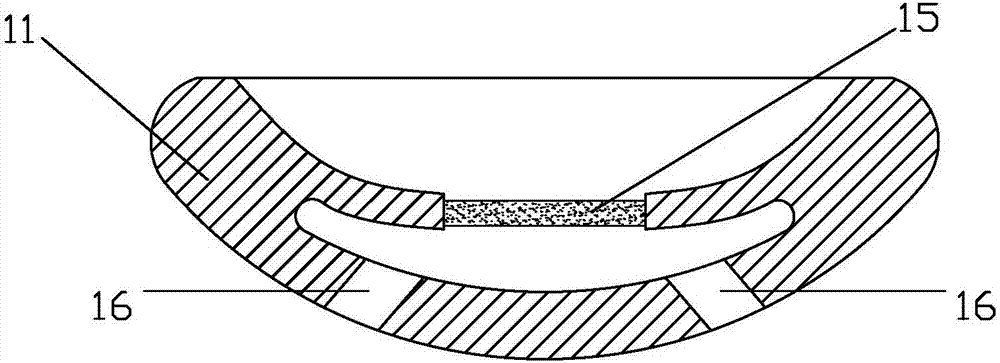

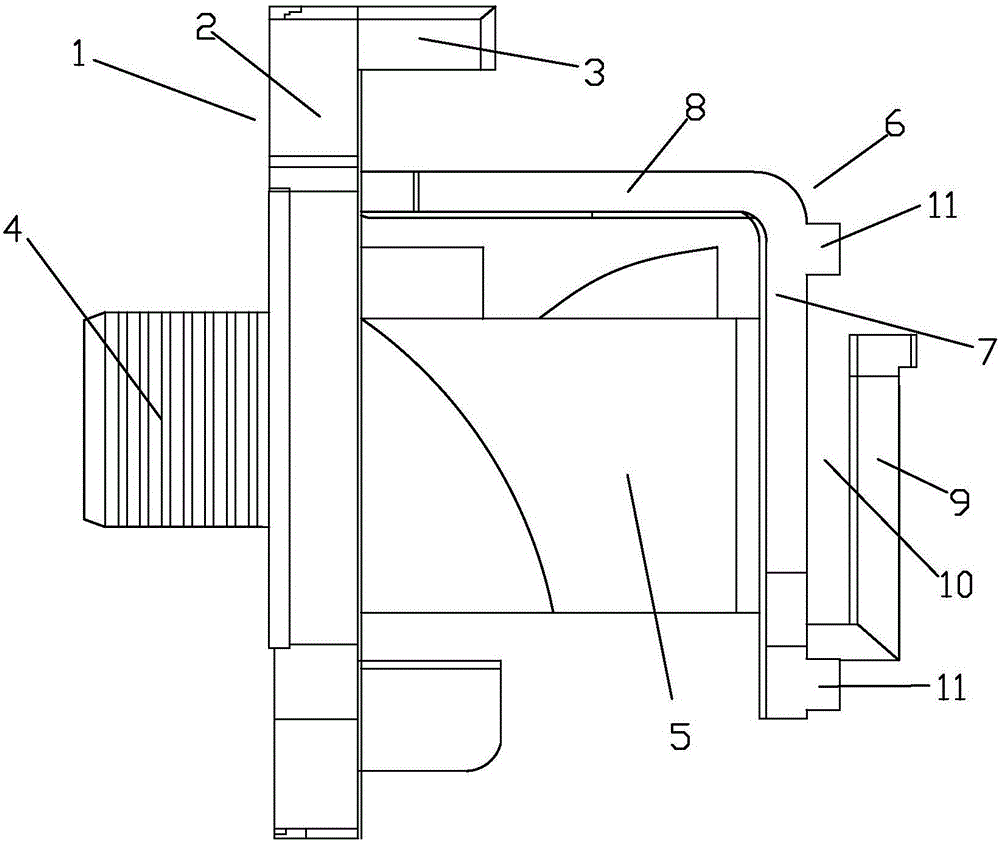

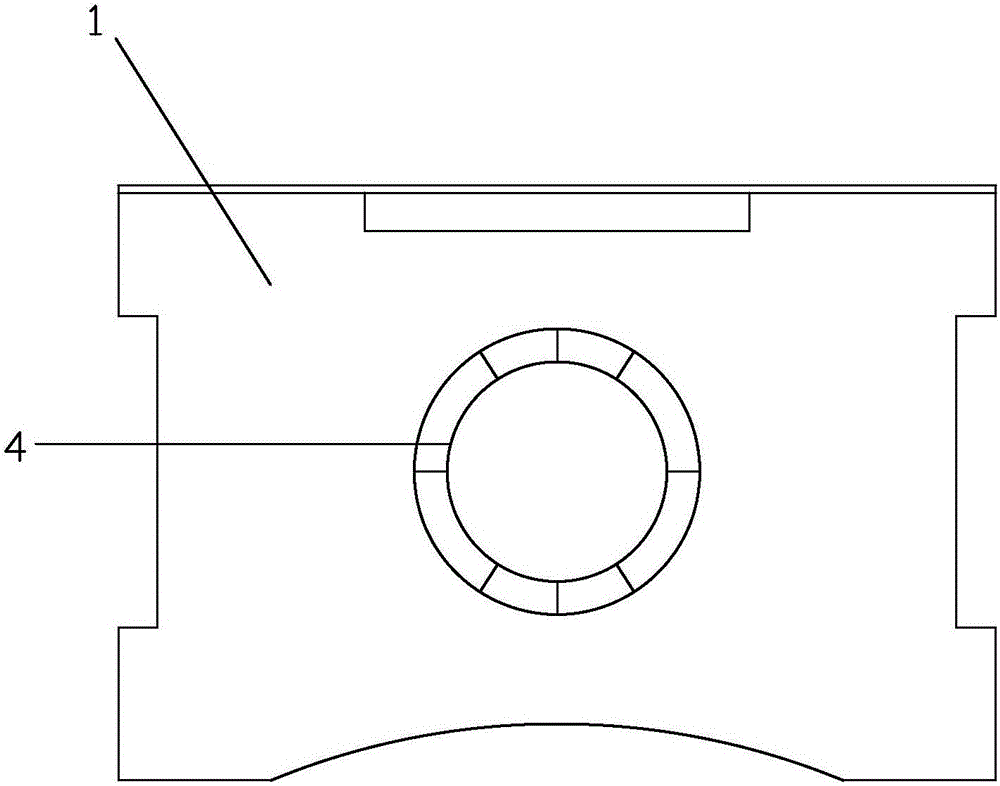

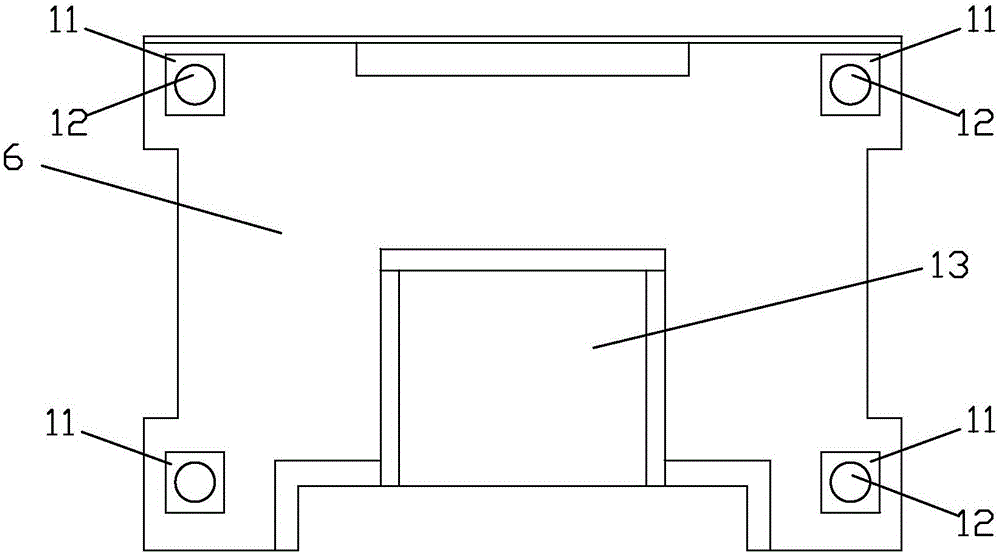

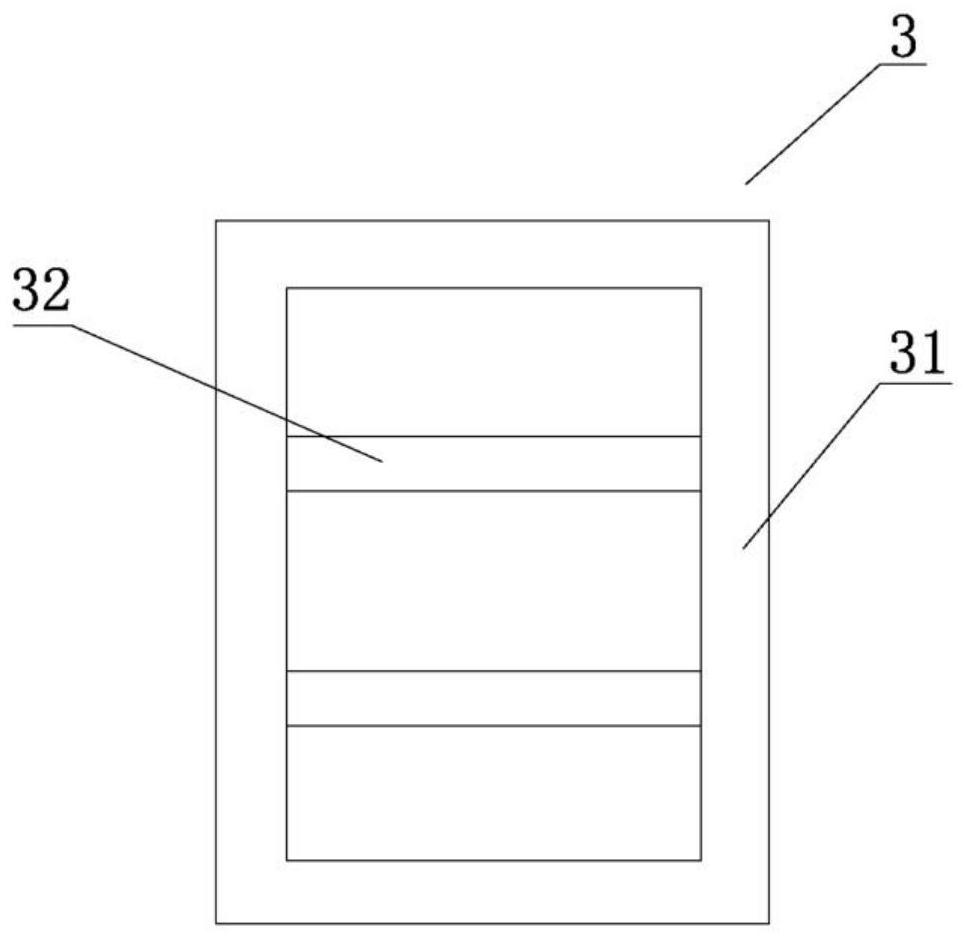

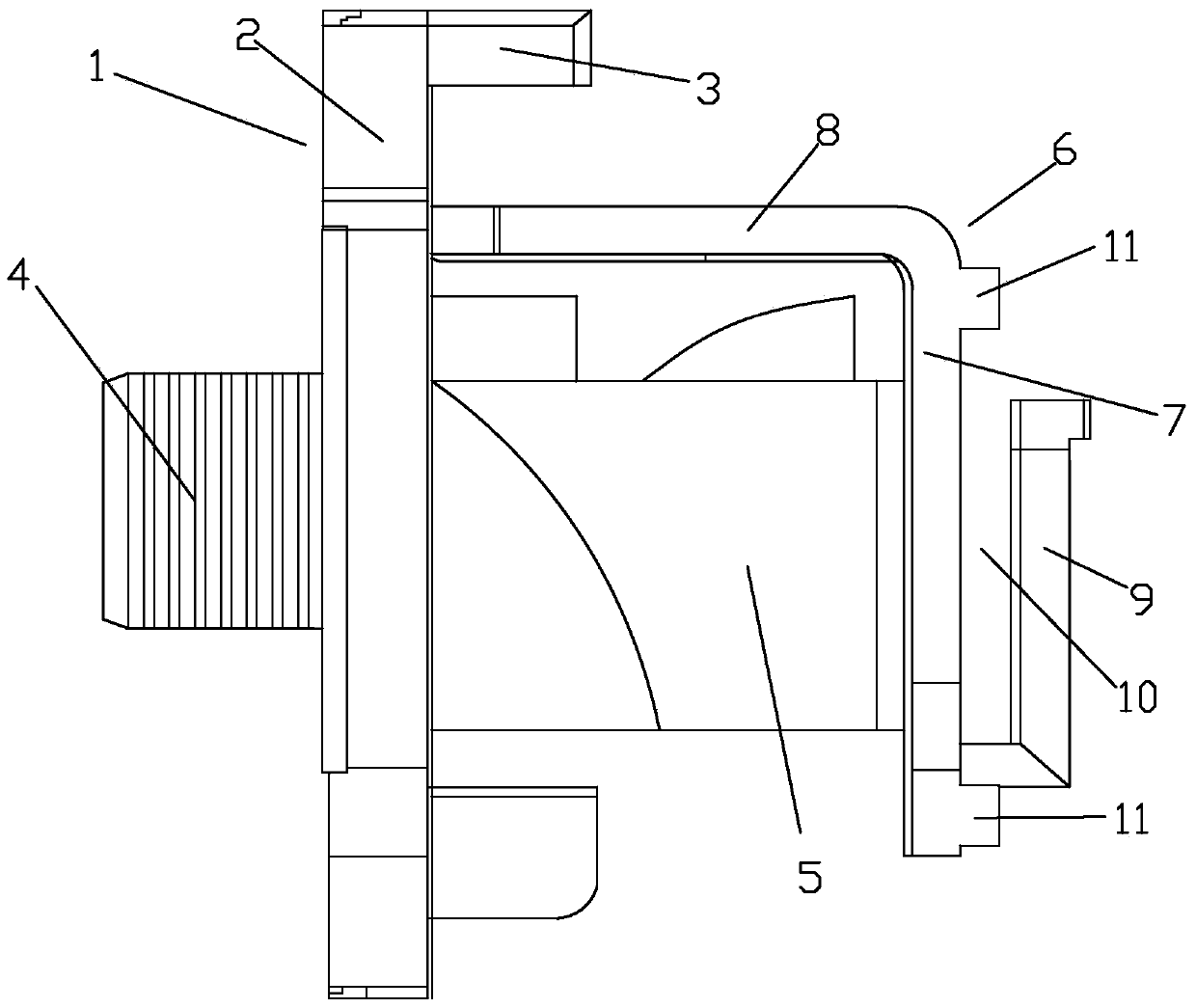

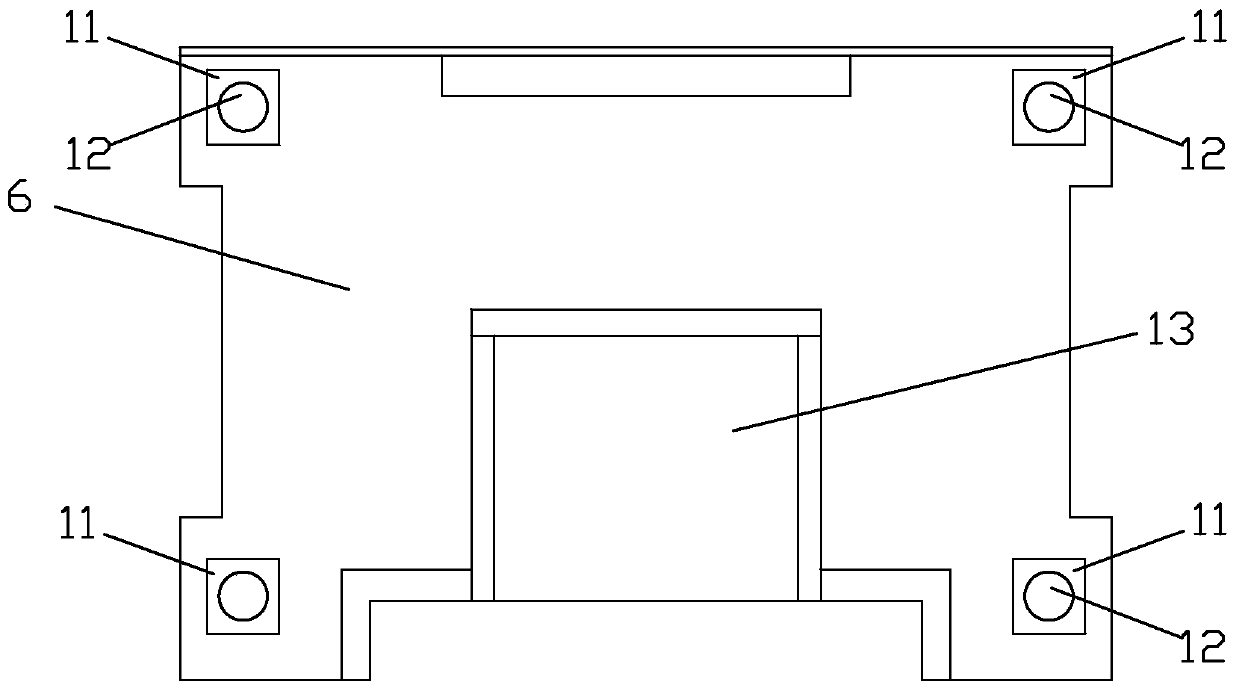

Gas-liquid separator for multi-connected heat pump and manufacturing method of gas-liquid separator

ActiveCN107388649AFast forming rateReduce defective rateRefrigeration componentsMaterials preparationVapor–liquid separator

The invention discloses a gas-liquid separator for a multi-connected heat pump and a manufacturing method of the gas-liquid separator. The gas-liquid separator comprises a barrel, a gas inlet pipe, a gas outlet pipe and a liquid outlet pipe, a gas-liquid separation coiler is connected to the gas inlet pipe, the other end of the gas-liquid separation coiler faces the gas outlet pipe, and a liquid pocket is connected to the lower end of the gas-liquid separation coiler; and a thermostatic controller is installed on the barrel and is used for maintaining the temperature in the device. The manufacturing steps of the gas-liquid separator include that (1) physical design of the gas-liquid separator is carried out; (2) sample testing of the gas-liquid separator is carried out; (3) material preparation is made; (4) part machining is carried out; (5) part assembling is carried out; (6) welding is carried out; and (7) aftertreatment is carried out. According to the manufacturing method, the molding rate is high, the inferior-quality product rate is low, the product quality is high, and huge economic benefits can be brought to enterprises; and the gas-liquid separator is high in separation efficiency, thorough in gas-liquid separation and long in service life.

Owner:青岛开拓隆海智控有限公司

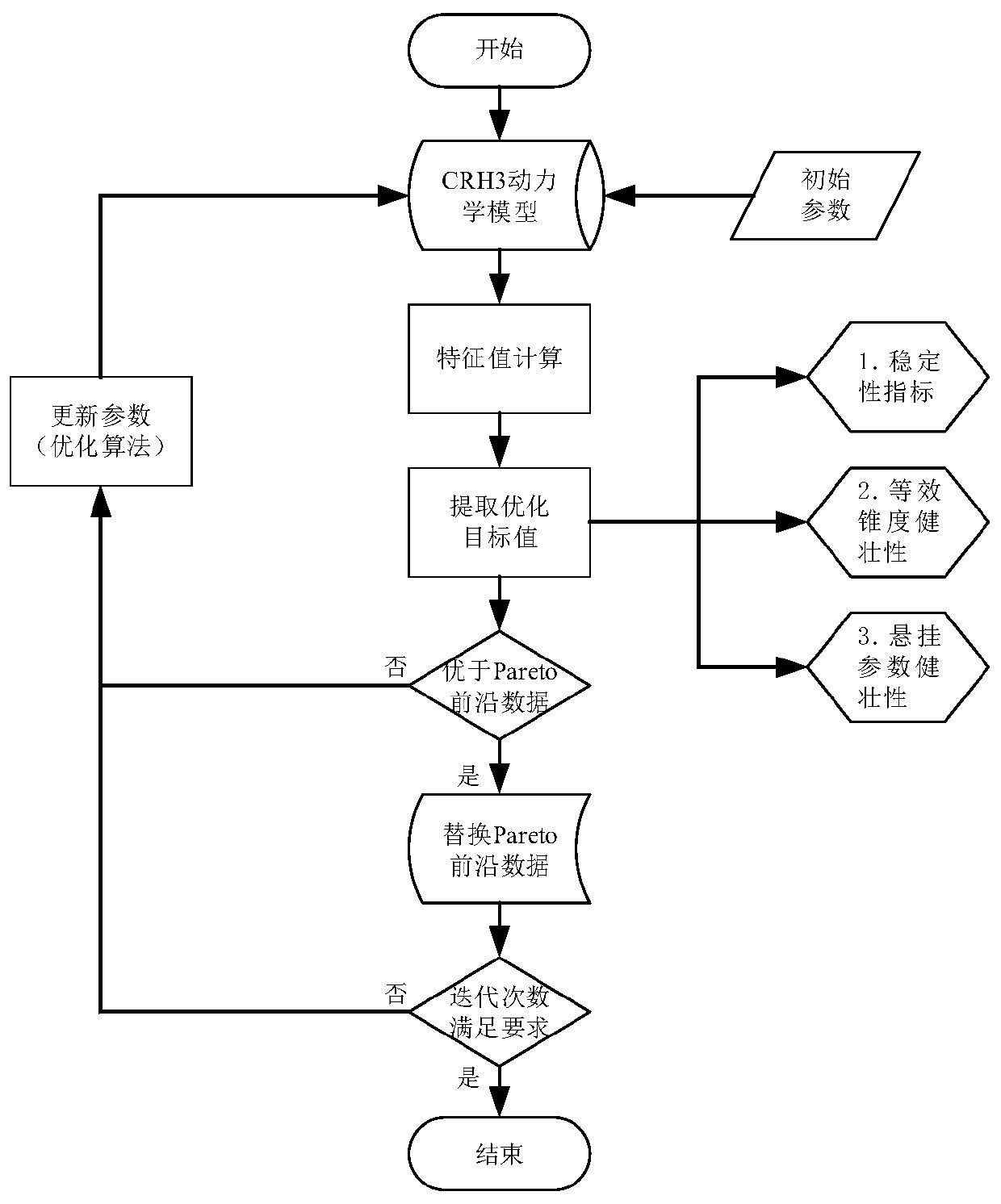

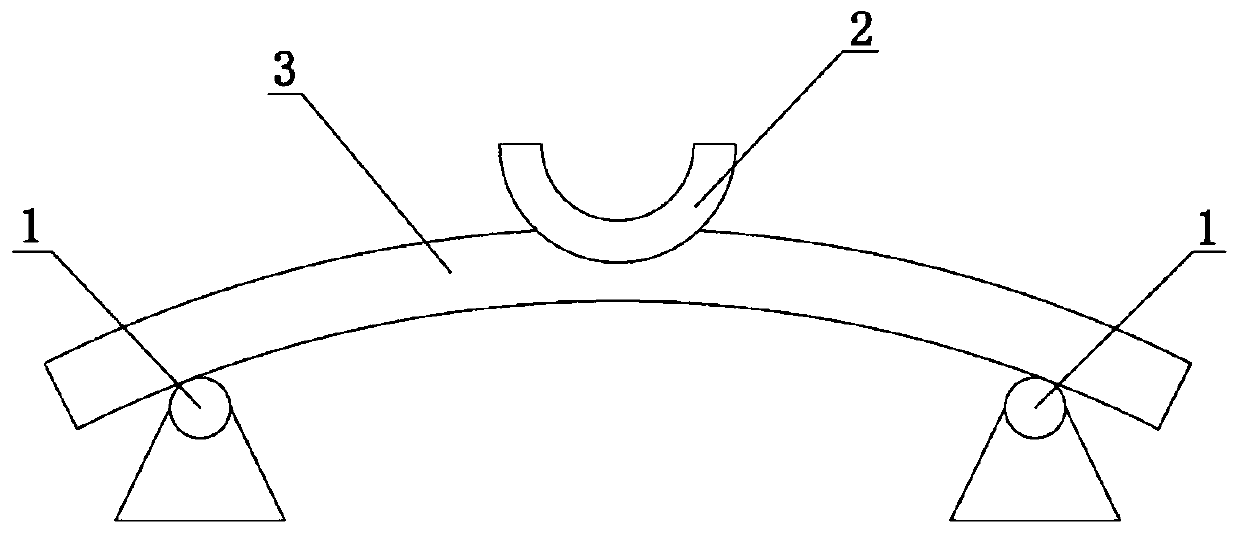

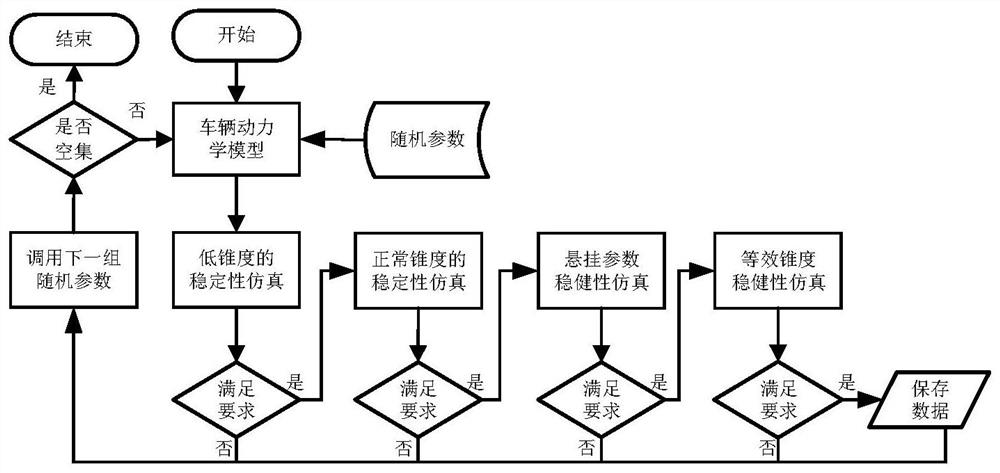

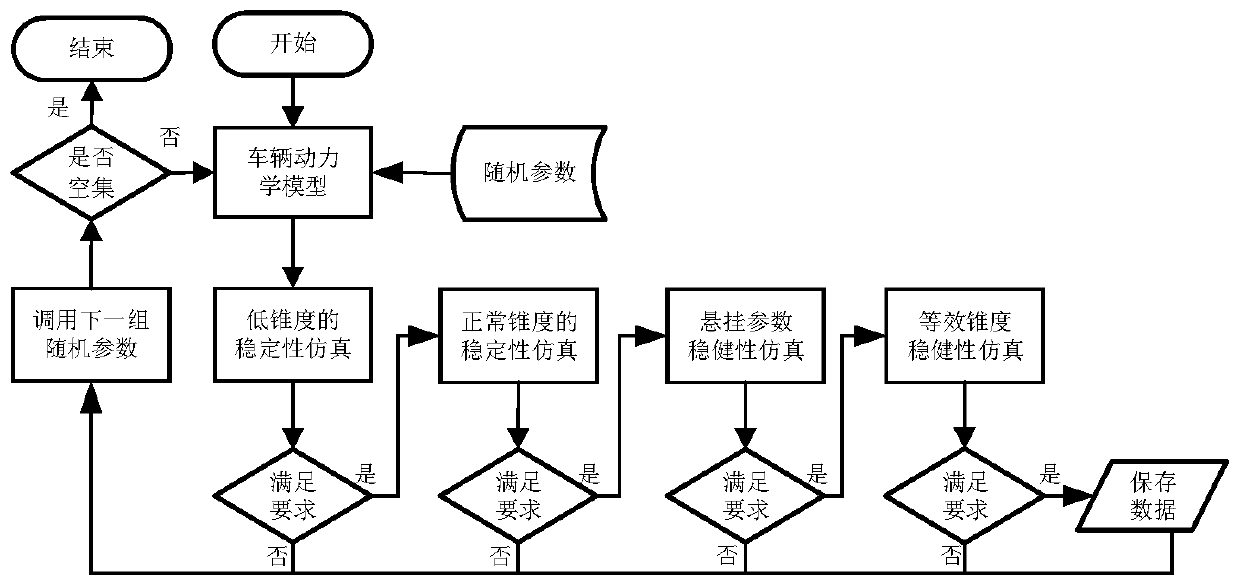

Bogie suspension parameter rapid optimization method

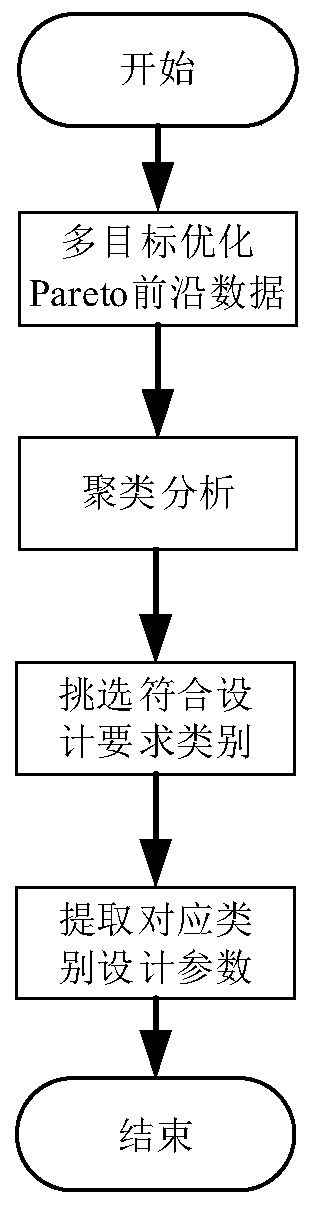

ActiveCN109918793ASimple designImprove analytical performanceCharacter and pattern recognitionSpecial data processing applicationsVehicle dynamicsLeading edge

The invention provides a bogie suspension parameter rapid optimization method, and relates to the technical field of suspension parameter optimization design of rolling stock. The method comprises thefollowing steps of establishing a vehicle dynamics simulation model; carrying out suspension parameter optimization analysis, determining an input variable, a value range and an output evaluation index required by the model, establishing a joint simulation module for vehicle dynamics, and setting a population size n, a crossover probability Pc, a variation probability Pm and an iteration frequency N by adopting a multi-objective optimization algorithm; performing characteristic value simulation calculation on the vehicle dynamics model according to the optimization target, and extracting an optimization target value obtained by simulation through a joint simulation interface; taking an output evaluation index value which is subjected to simulation optimization and meets an evaluation index range for the first time as Pareto leading edge data; and finally, enabling the optimized data to be processed to obtain K representative suspension parameter set categories, the categories meetingthe design requirements are selected from the K representative suspension parameter set categories, and the corresponding parameter sets are optimized bogie suspension parameters.

Owner:SOUTHWEST JIAOTONG UNIV

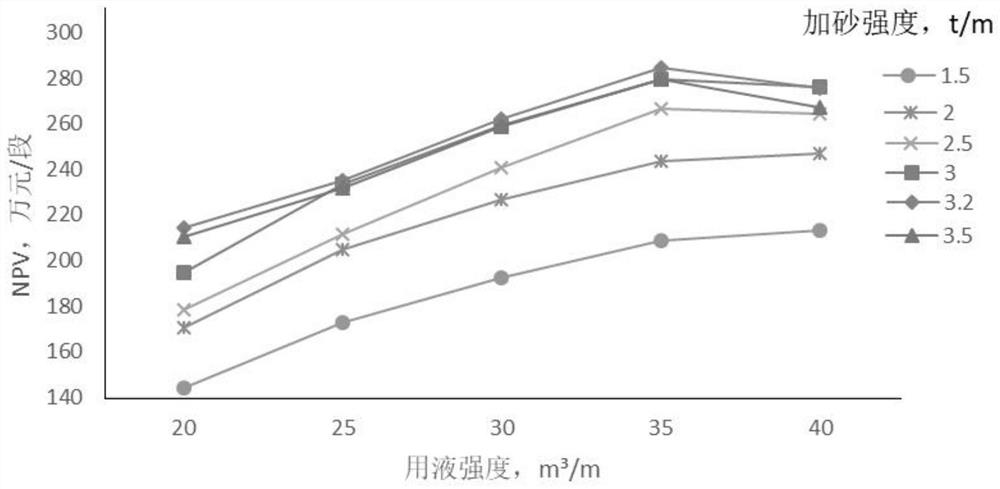

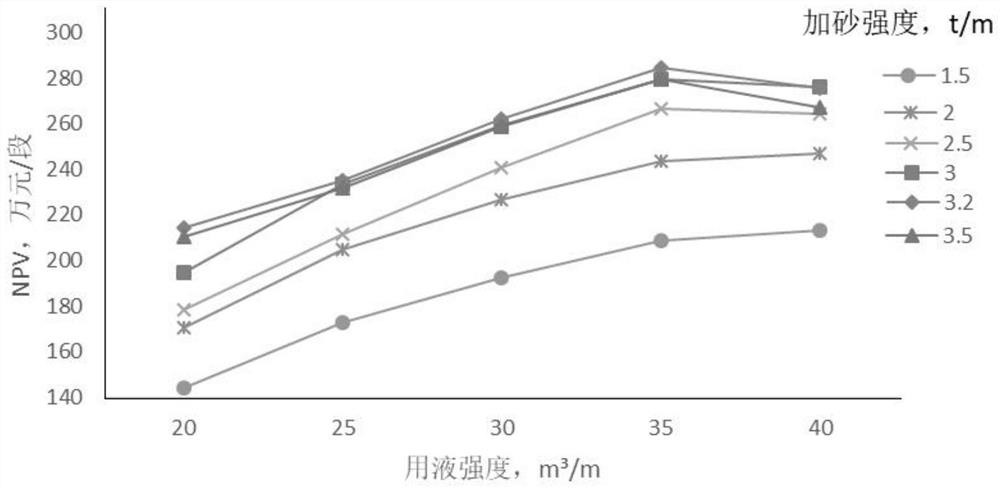

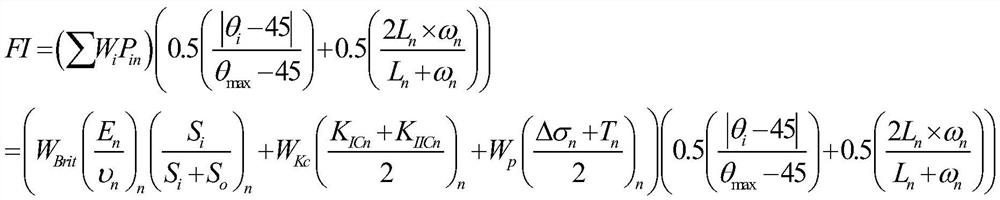

Deep shale gas reservoir fracturing optimization method based on compressibility evaluation

ActiveCN113312785AComprehensive Compressibility CharacterizationReliable optimization resultsFluid removalDesign optimisation/simulationShale gasGeophysics

The invention discloses a deep shale gas reservoir fracturing optimization method based on compressibility evaluation. The method comprises the following steps: obtaining geological parameters, and building a three-dimensional geological model; carrying out gridding subdivision on the geological model, and calculating comprehensive compressibility indexes of all geological grids respectively; dividing all the geological grids into three levels according to the comprehensive compressibility index, and classifying the geological grids at the same level into a compressibility fracturing section at the same level; carrying out production simulation on each stage of compressible fracturing section under the conditions of fixing liquid strength and different sand adding strength, and obtaining different stages of construction curves, wherein the highest inflection point of the curve is an optimal fracturing design parameter; and calculating a to-be-researched well to obtain the stage number of the layer sections of the to-be-researched well, and directly selecting the optimal fracturing design parameters of the stage determined in the previous step as the optimal construction parameters according to the calculated stage number. More comprehensive compressibility characterization of the fractured interval is obtained, finer fracturing design parameter optimization is carried out for each fractured interval, the optimization result is more reliable, and the method has practical significance.

Owner:SOUTHWEST PETROLEUM UNIV

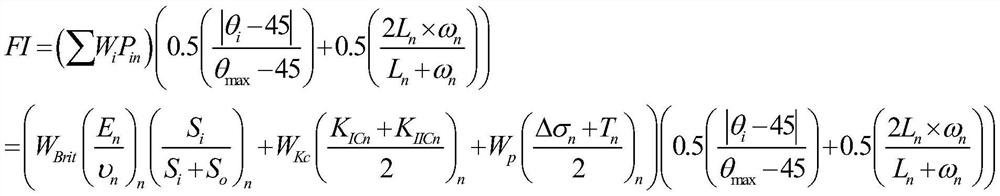

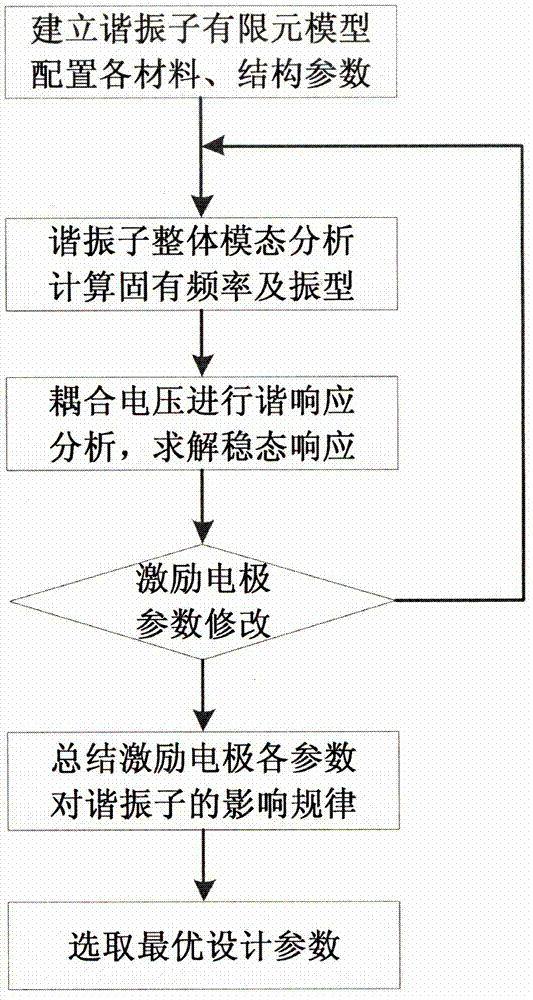

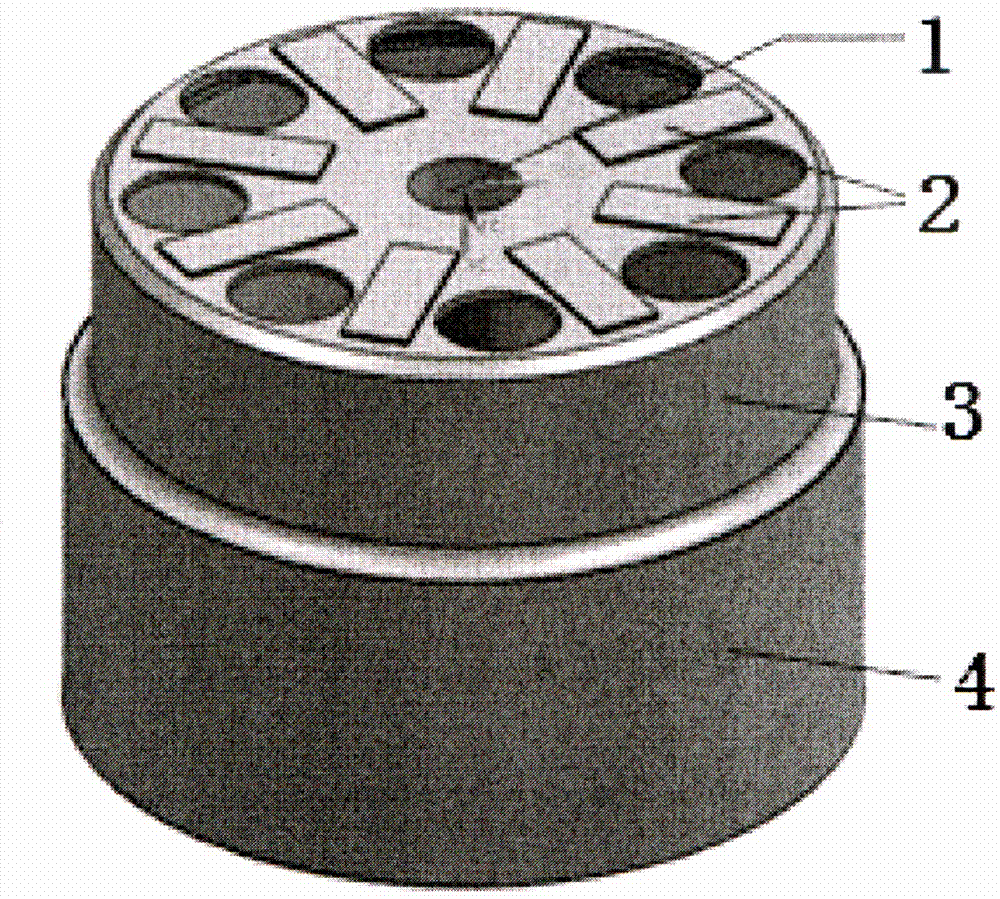

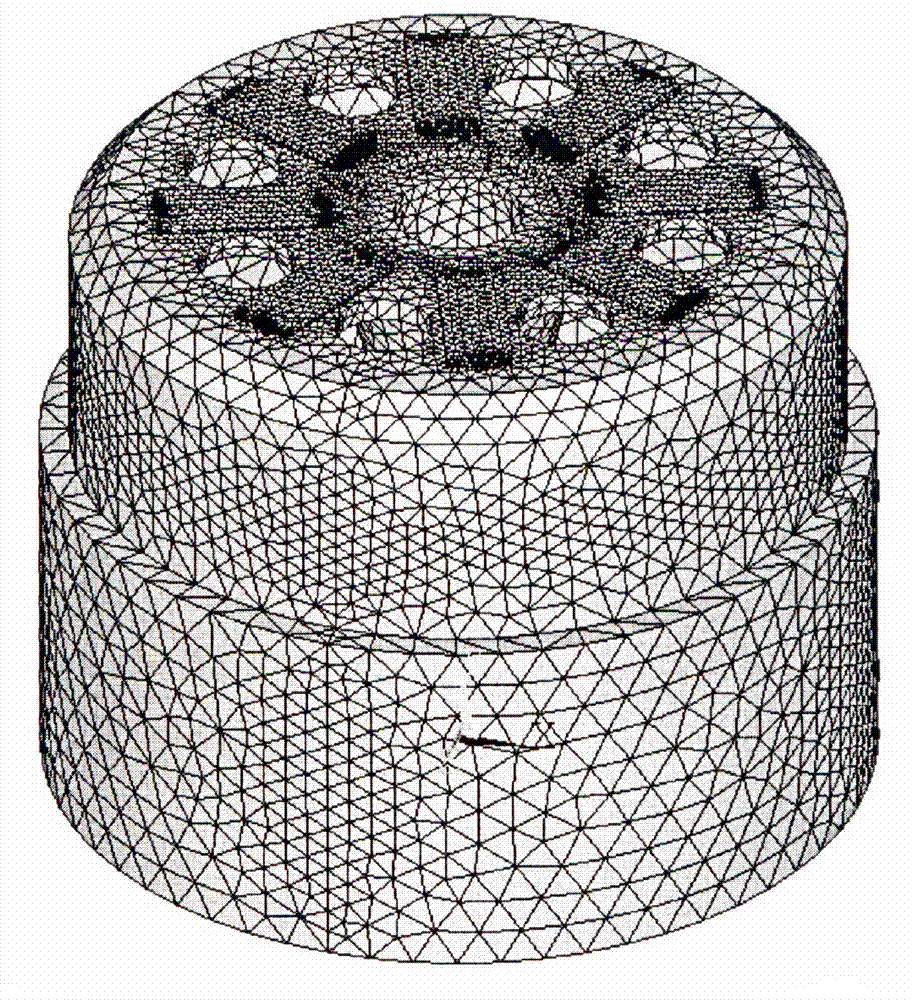

Optimal design method for exciting electrode of piezoelectric vibration gyro

ActiveCN102968540BImprove abilitiesImprove accuracySpecial data processing applicationsElectricityElement model

The invention relates to an optimal design method for an exciting electrode of a piezoelectric vibration gyro. The method comprises the following steps: (1) establishing a finite element model of the piezoelectric vibration gyro and configuring material and structure parameters of each part according to the actual condition; (2) performing modal analysis to obtain the inherent frequency and the relevant vibration mode of a harmonic oscillator, applying sine exciting voltage to a piezoelectric electrode on the basis, and performing harmonic response analysis; (3) deducing the influence rule of each parameter of the exciting electrode on the harmonic oscillator through the analysis result of the step (2); and (4) based on comprehensive consideration in many respects, selecting optimal design parameters. By the method, a definite element emulation analysis method is adopted, the defects of an experience cut-and-try method are overcome, the design efficiency and accuracy of the exciting electrode are improved, the research and development cost is reduced, the research and development process is accelerated, and a reference is provided for reasonable design of the exciting electrode of the piezoelectric vibration gyro.

Owner:BEIJING INFORMATION SCI & TECH UNIV +1

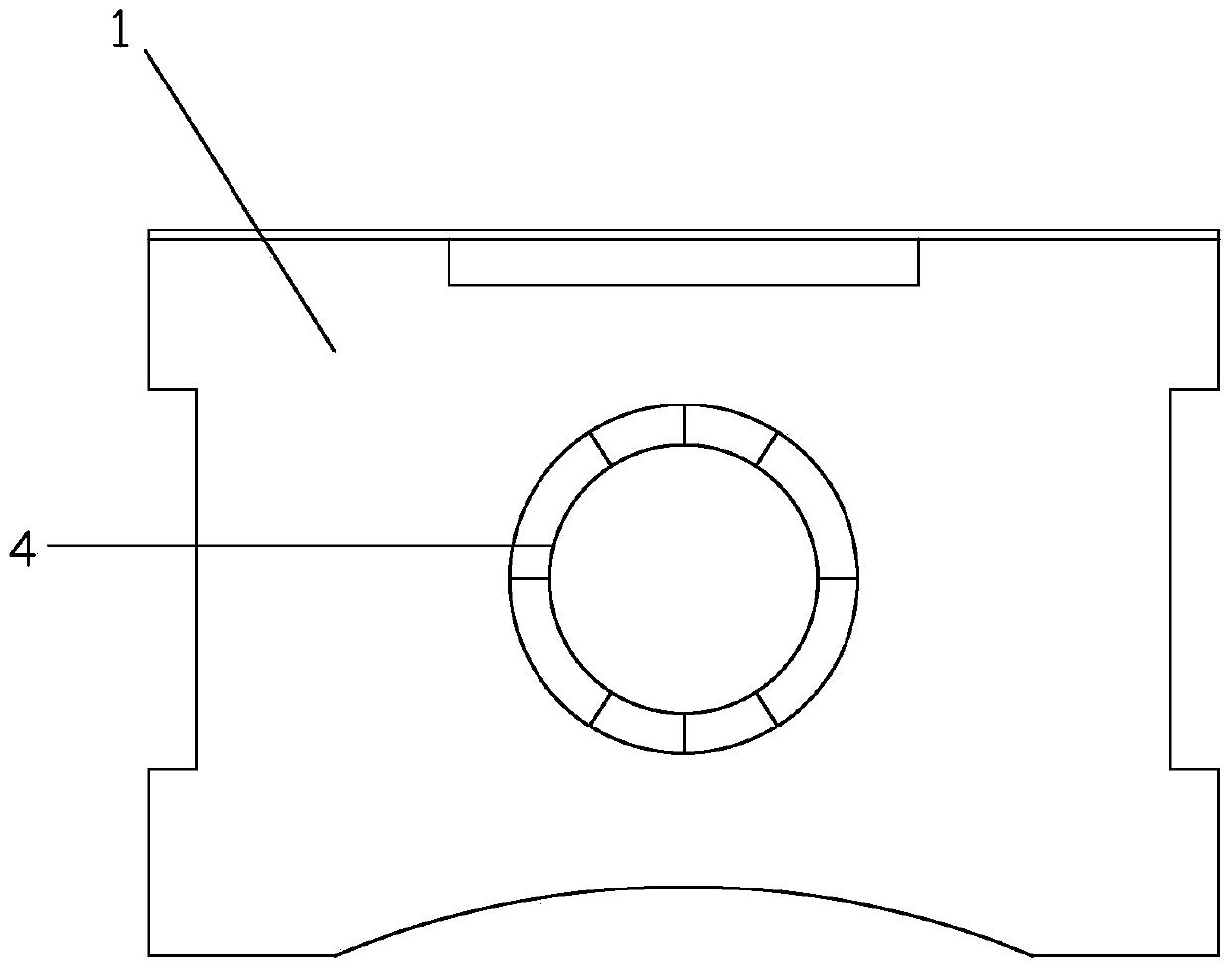

High-precision automobile steering gear bracket and manufacturing method thereof

ActiveCN106114610APrevent looseningMeet the mechanical requirementsGeometric CADSpecial data processing applicationsDie castingMechanical engineering

The invention discloses a high-precision automobile steering gear bracket and a manufacturing method thereof. The steering gear bracket comprises a fixing base, a mounting base and a connecting plate, wherein a rotary table is mounted in the fixing base; locking screw rods are connected to the rotary table; a U-shaped connecting piece and screw holes are connected to the side surface of the mounting base; a mounting groove is formed in the U-shaped connecting piece; a hydraulic oil cylinder is arranged in the connecting plate; a piston rod is connected to the hydraulic oil cylinder; and a press block is connected to the piston rod. The manufacturing method of the steering gear bracket comprises the following steps of (1) designing the structure of the steering gear bracket; (2) performing sample test; (3) performing simulated die-casting on the steering gear bracket; (4) performing simulated die-casting; and (5) performing die-casting of the steering gear bracket. Compared with the prior art, mechanical analysis of models and mechanical test of real objects are respectively performed on the steering gear bracket disclosed by the invention, so that mechanical defects of a conventional steering gear bracket are thoroughly rejected, all the mechanical requirements are met, the quality of products is improved, and the steering gear bracket disclosed by the invention has tremendous potential economic value.

Owner:XINCHANG XINCHAI MACHINERY CO LTD

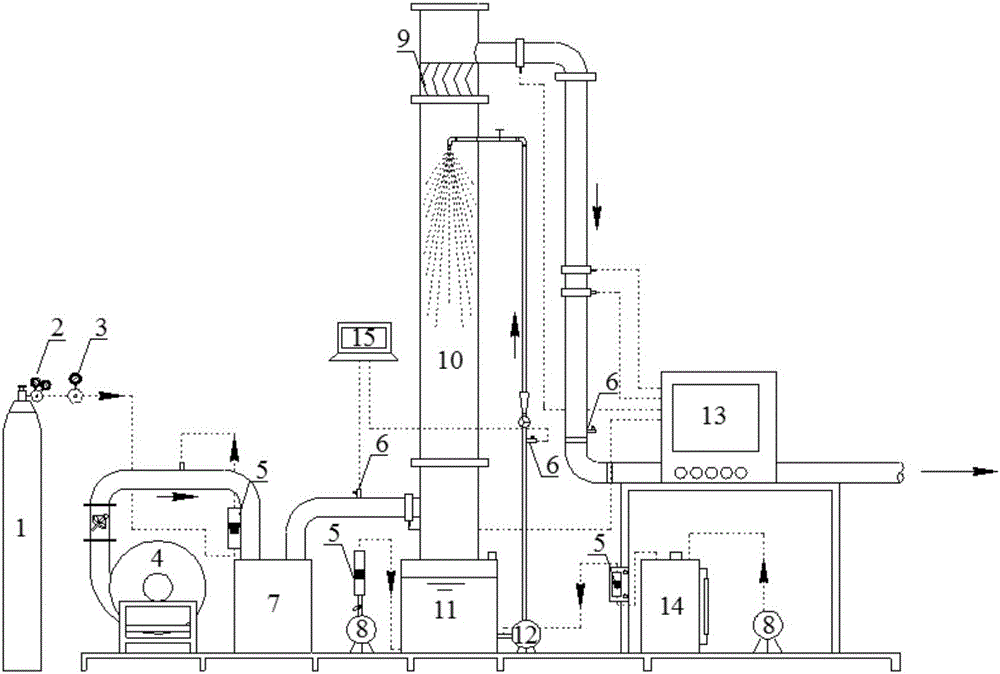

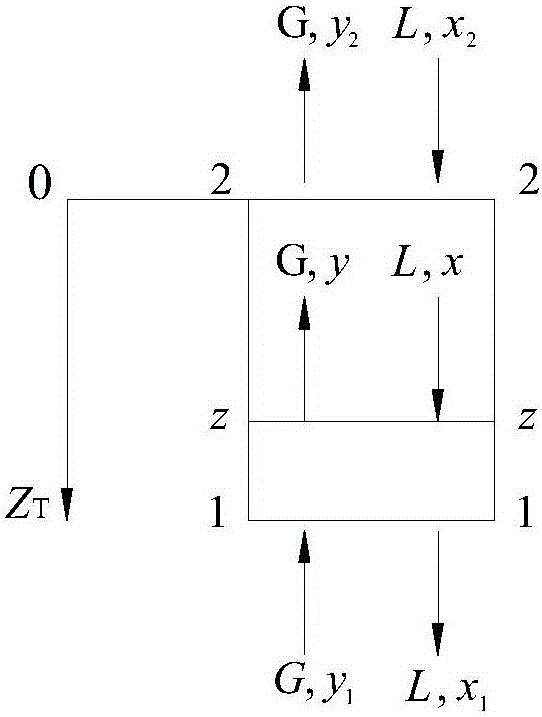

Calculation model for design and operation of ammonia process desulfurization spray tower and optimized regulation method

ActiveCN105964123AAccurately reflectReliable optimization resultsGas treatmentDispersed particle separationLiquid dynamicsMathematical model

The invention discloses a calculation model for design and operation of an ammonia process desulfurization spray tower and an optimized regulation method and belongs to the technical field of ammonia process smoke desulfurization. Firstly, based on the characteristics of the ammonia process desulfurization process, the pH value, the smoke flow rate and the liquid-gas ratio are selected as parameters, and an ammonia process desulfurization SO2 absorption mass transfer coefficient expression with general applicability is established. On the basis, ionic-charge charge conservation and element material charge conservation in a liquid phase are analyzed, the gas-liquid dynamic balance relation in the SO2 absorption process in the spray tower is established through the combination with the thermodynamic property and ionic equilibrium principle of an NH3-SO2-H2O system, and a mathematic model capable of reflecting the spray tower ammonia process desulfurization SO2 absorption process is established. By means of the model, the influences of different technological conditions on the ammonia process desulfurization SO2 removal rate can be calculated, a theoretical direction can be provided for design and operation of the ammonia process desulfurization absorption tower in the industry, and great practical significance and engineering application value are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

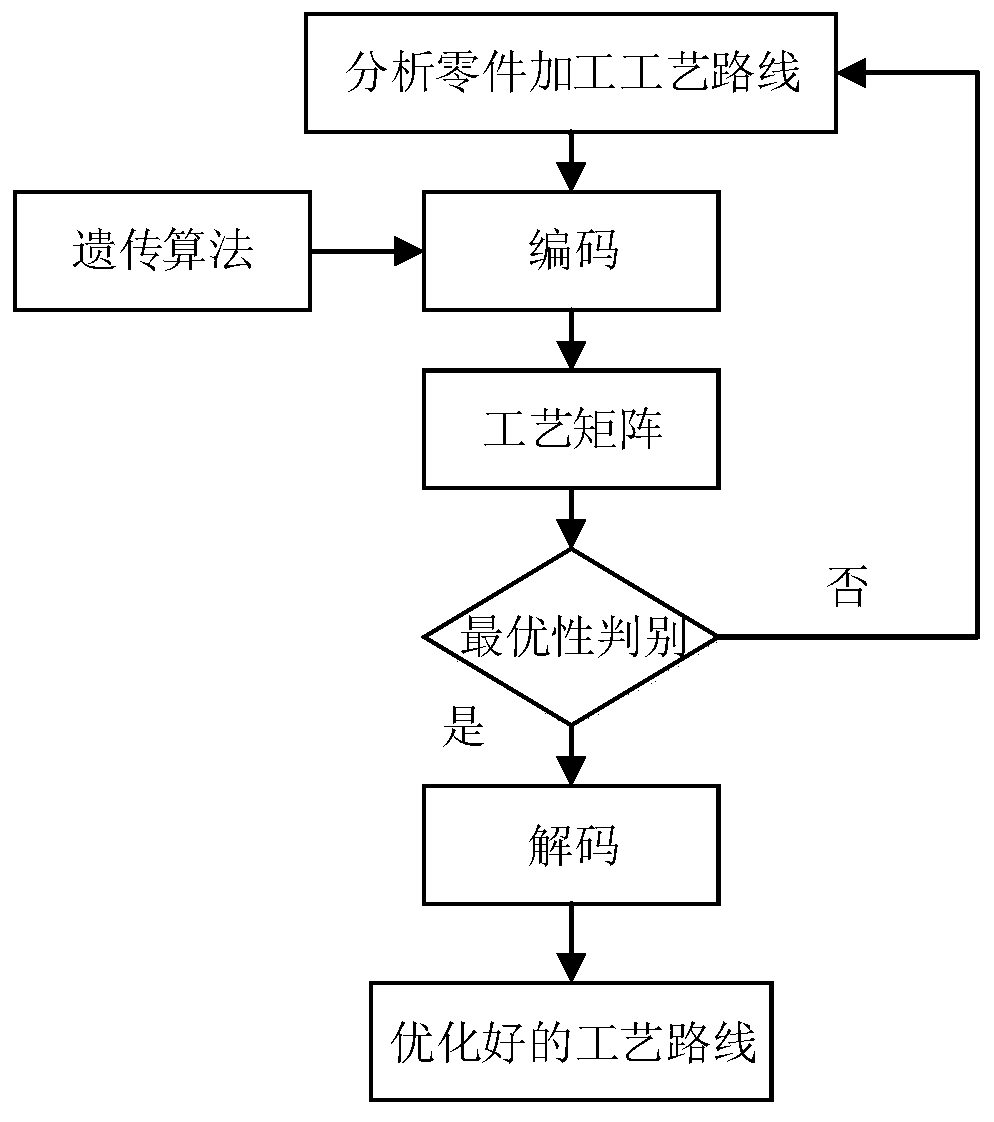

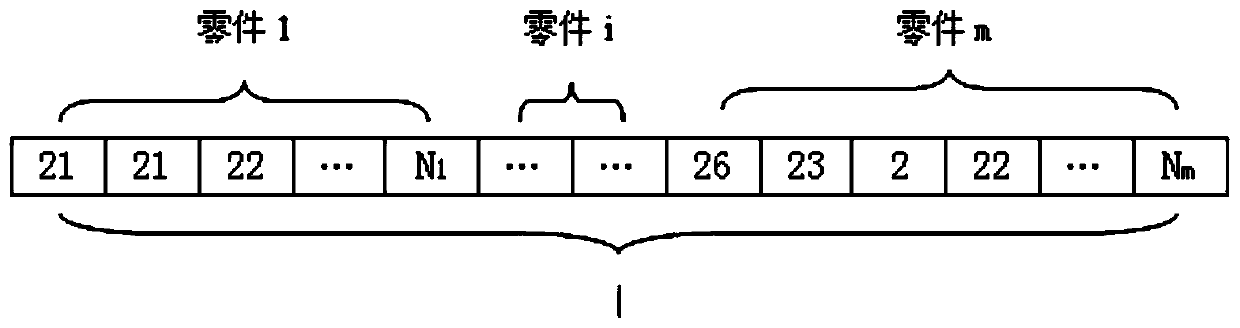

Complex product production line performance optimization method based on genetic algorithm

InactiveCN110084416AImprove performanceImplement searchForecastingArtificial lifeProduction lineGenetic algorithm

The invention provides a complex product production line performance optimization method based on a genetic algorithm, and the method comprises the steps: analyzing each part machining process route of a complex product, and determining all completed part machining characteristics of each machining process; generating a manufacturing node-oriented processing process route according to the constraint of each processing feature selectable equipment set, and coding the manufacturing node-oriented processing process route; and carrying out optimality discrimination on the complex product processing process matrix, and if the requirement is met, decoding according to the mapping relation to generate a part processing process route with good performance optimization. According to the invention,a genetic algorithm is adopted, an integer coding model is adopted, and crossover and variation operations are carried out in a range of the selectable equipment set limited by manufacturing features,so that searching and selection of a process route are realized. According to the method, two problems of reliability and balance of a complex product production line are comprehensively considered,an optimal solution is sought in a huge feasible solution space, and an optimization result is more reliable.

Owner:JIANGSU UNIV OF TECH

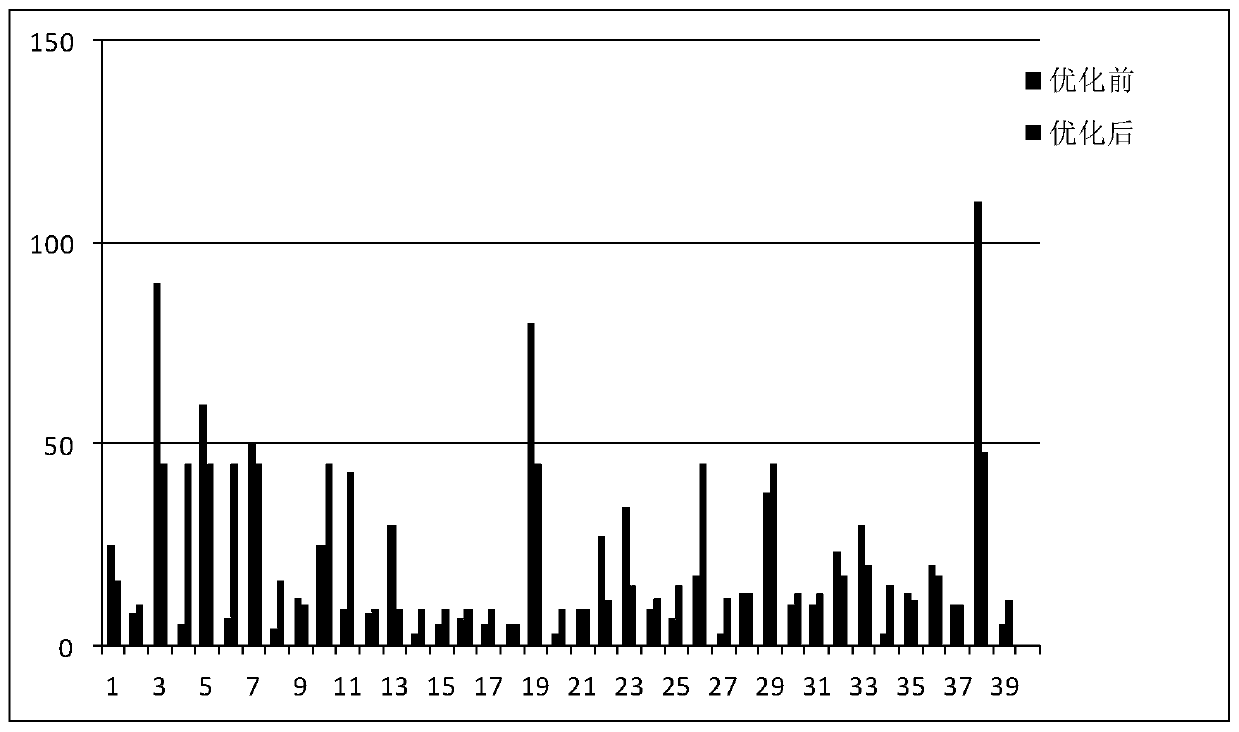

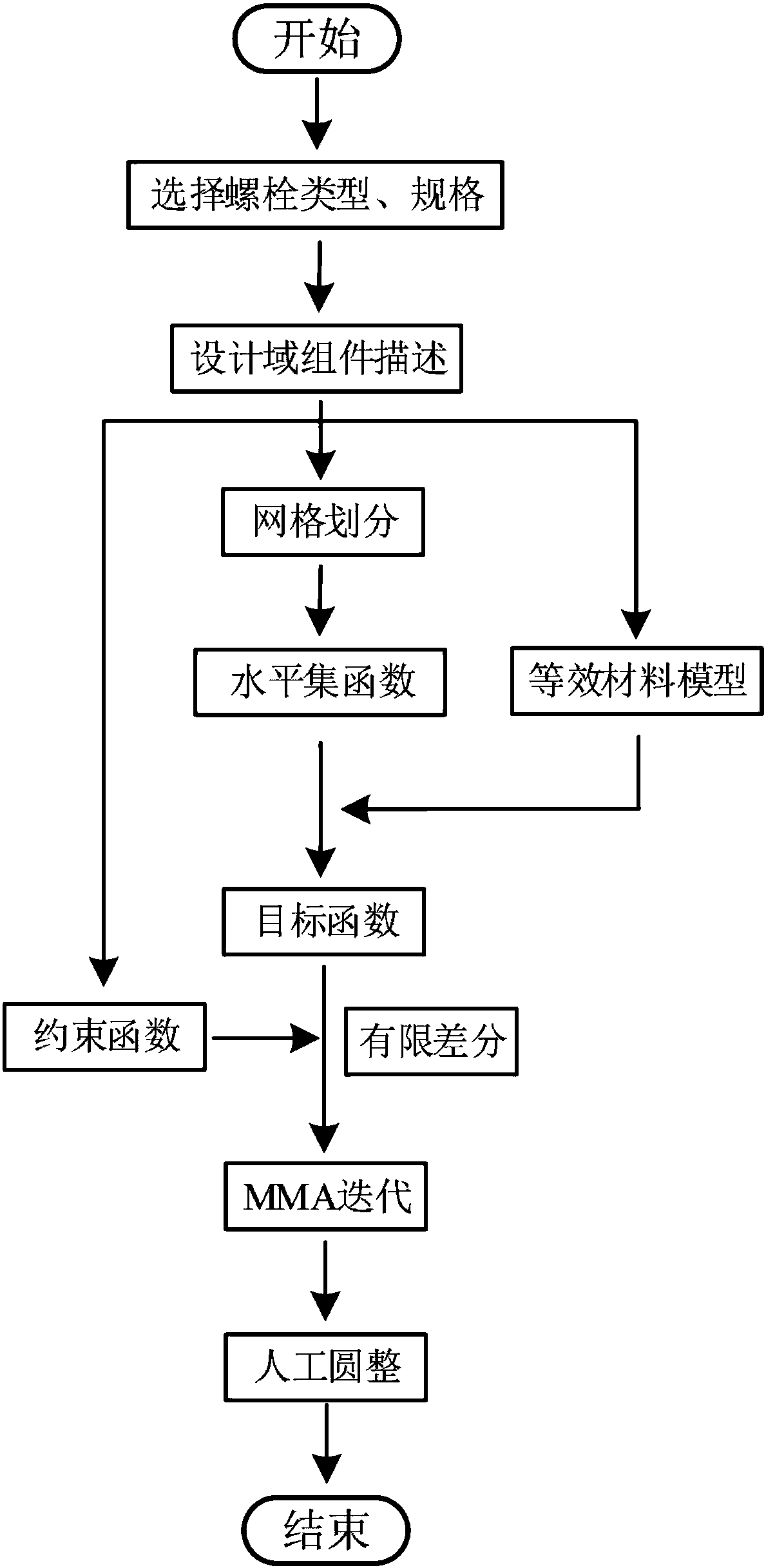

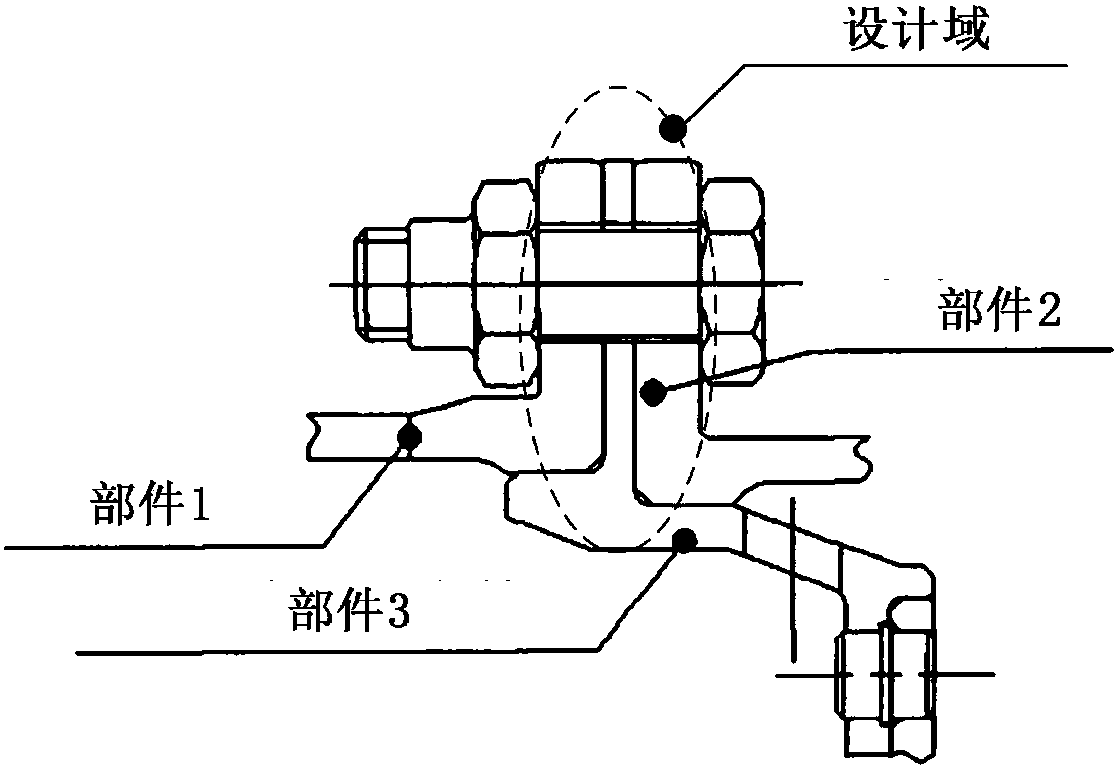

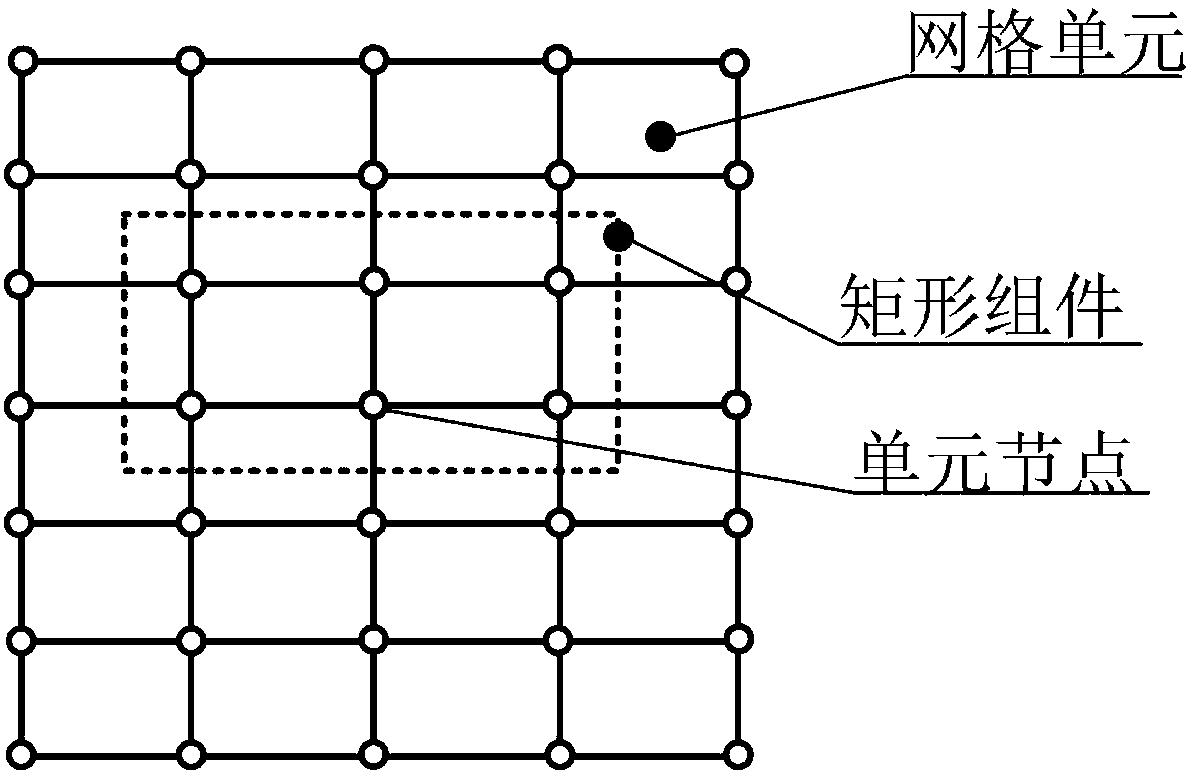

Optimum design method of dynamic performance of aero-engine fastening junction surface

ActiveCN108197397AImprove optimization resultsClear boundariesGeometric CADDesign optimisation/simulationAviationEngineering

The invention discloses an optimum design method of the dynamic performance of an aero-engine fastening junction surface. The optimum design method comprises the steps of firstly, determining the type, the specification, the assembly technology and the machining precision of adopted bolts; then selecting the aero-engine part fastening junction surface as a design domain, and using a rectangular assembly for description; then adopting several small four-node quadrilateral meshes to divide the design domain, then constructing a rectangular level set function, equalizing the design domain into amaterial model to obtain a unit equivalent rigidity matrix, assembling the equivalent rigidity matrix, and extracting a mass matrix of parts to obtain a kinetic equation and then a target function; then constraining center coordinates of the assembly in the design domain, then conducting iterative optimization, and finally, conducting rounding processing to thus obtain the junction surface joint form with the optimal dynamic performance. By means of the optimum design method of the dynamic performance of the aero-engine fastening junction surface, through optimal design of the junction surface, the optimal solution of the relevant dynamic performance is solved, and a clear design boundary is obtained.

Owner:XI AN JIAOTONG UNIV

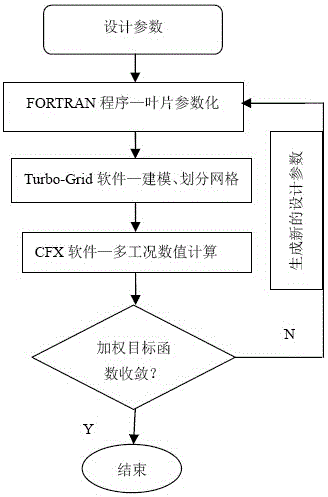

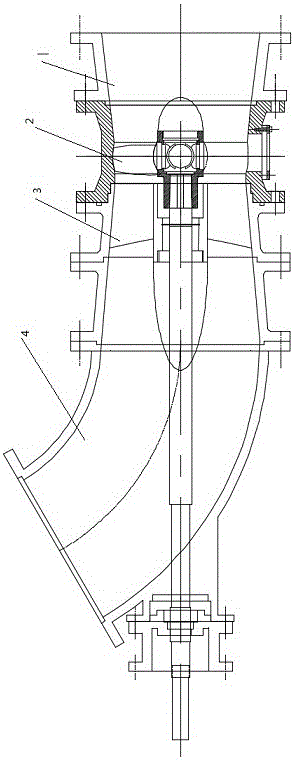

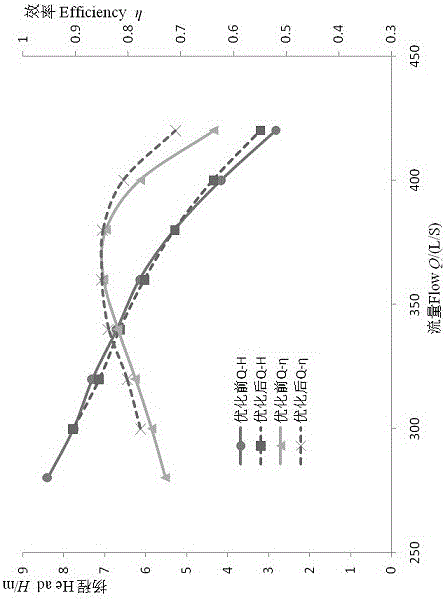

A Design Method of Axial Flow Pump Impeller under All Working Conditions

ActiveCN105179303BImprove efficiencyWide efficiency curvePump componentsPumpsAxial-flow pumpImpeller

A method for designing the impeller of an axial flow pump under full working conditions, comprising the following steps: (1) Parametric modeling of the impeller of the axial flow pump: selecting k airfoil sections of the axial flow pump impeller, the cascade density and the total value of the airfoil placement angle 2k design parameters; (2) Optimal design for all working conditions: First, determine the conventional design parameters of the impeller; then perform numerical calculations on the design working conditions of the axial flow pump impeller, comprehensively analyze various losses in the pump, and minimize the total loss Preliminary design of a pair of axial flow pump impellers with better hydraulic performance under the design working conditions; second, design guide vanes, water guide cones and water inlet and outlet channels for the impeller; The optimal weighted average efficiency is the goal, and the head is the constraint condition. The sequential quadratic programming method of the gradient optimization algorithm is used to continuously change the design parameters of the axial flow pump impeller, and iterative numerical calculations are performed on the pump device. The invention adopts CFD numerical calculation, has high design precision and reliable optimization result.

Owner:YANGZHOU UNIV

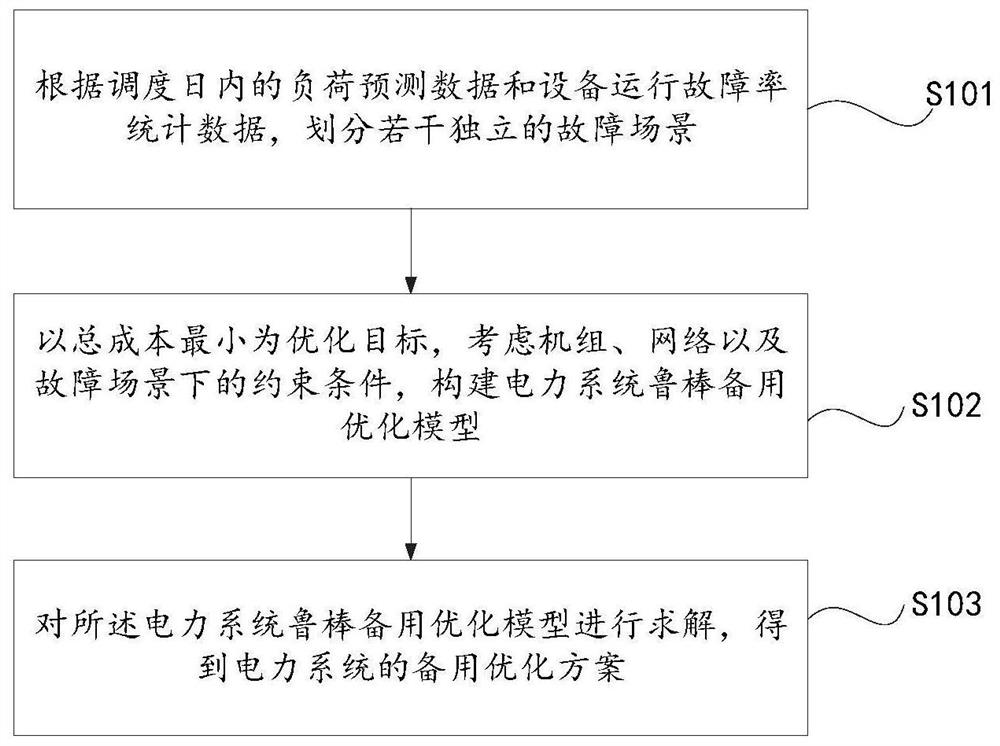

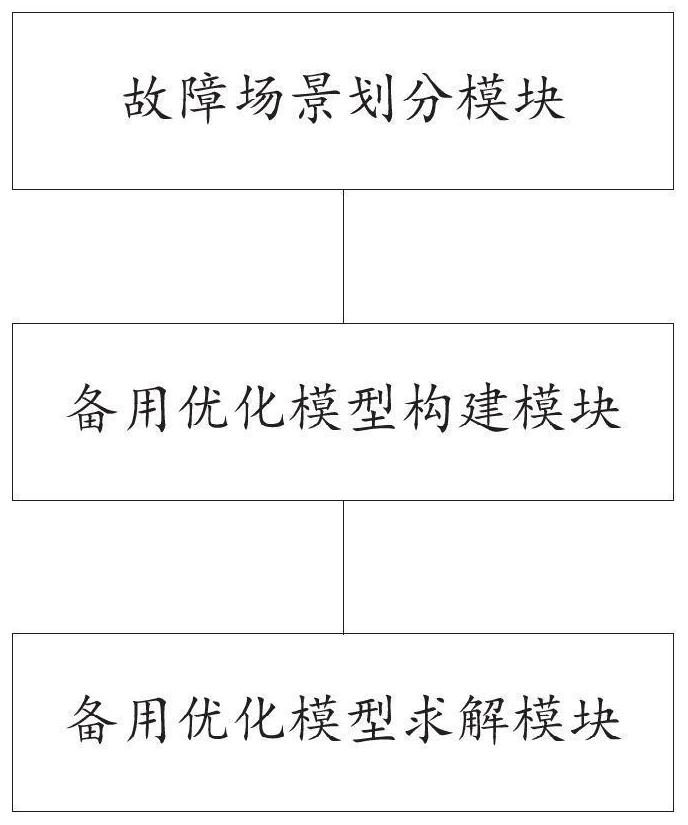

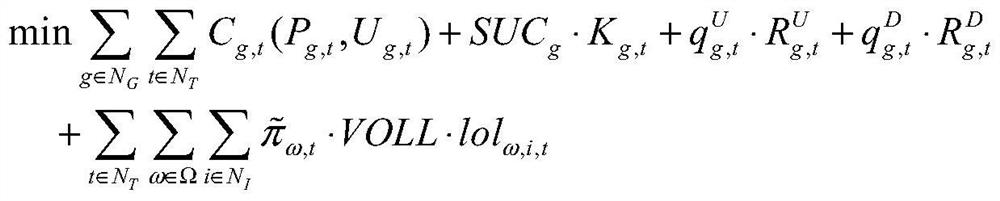

Power system standby optimization method and system considering multiple fault scenes

ActiveCN112597633AHigh engineering application valueFull simulation runForecastingDesign optimisation/simulationLoad forecastingMultiple fault

The invention discloses a power system standby optimization method and system considering multiple fault scenes, and the method comprises the steps of dividing a plurality of independent fault scenesaccording to the load prediction data and equipment operation fault rate statistical data in a dispatching day; constructing a robust standby optimization model of the power system by taking minimum total cost as an optimization target and considering constraint conditions of a unit, a network and a fault scene; and solving the robust standby optimization model of the power system to obtain a standby optimization scheme of the power system. According to the invention, a power system robust random standby optimization model considering multiple fault scenes and fault probability uncertainty isconstructed. According to the invention, the system reserve capacity can be optimized under the condition of considering multiple fault scenes and uncertainty of the multiple fault scenes, a robust optimization uncertainty description method is adopted, simulation operation is more comprehensive, an optimization result is more reliable and comprehensive, and the engineering application value of power system reserve configuration is improved.

Owner:SHANDONG UNIV

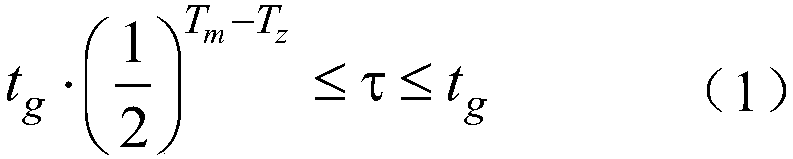

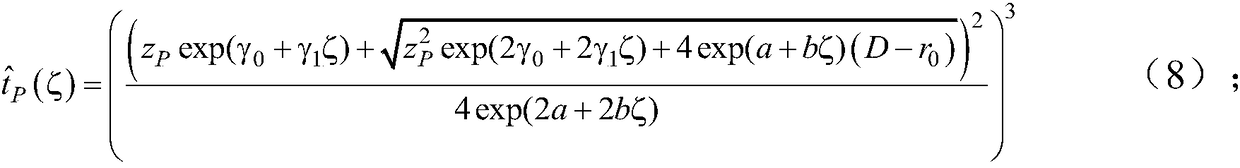

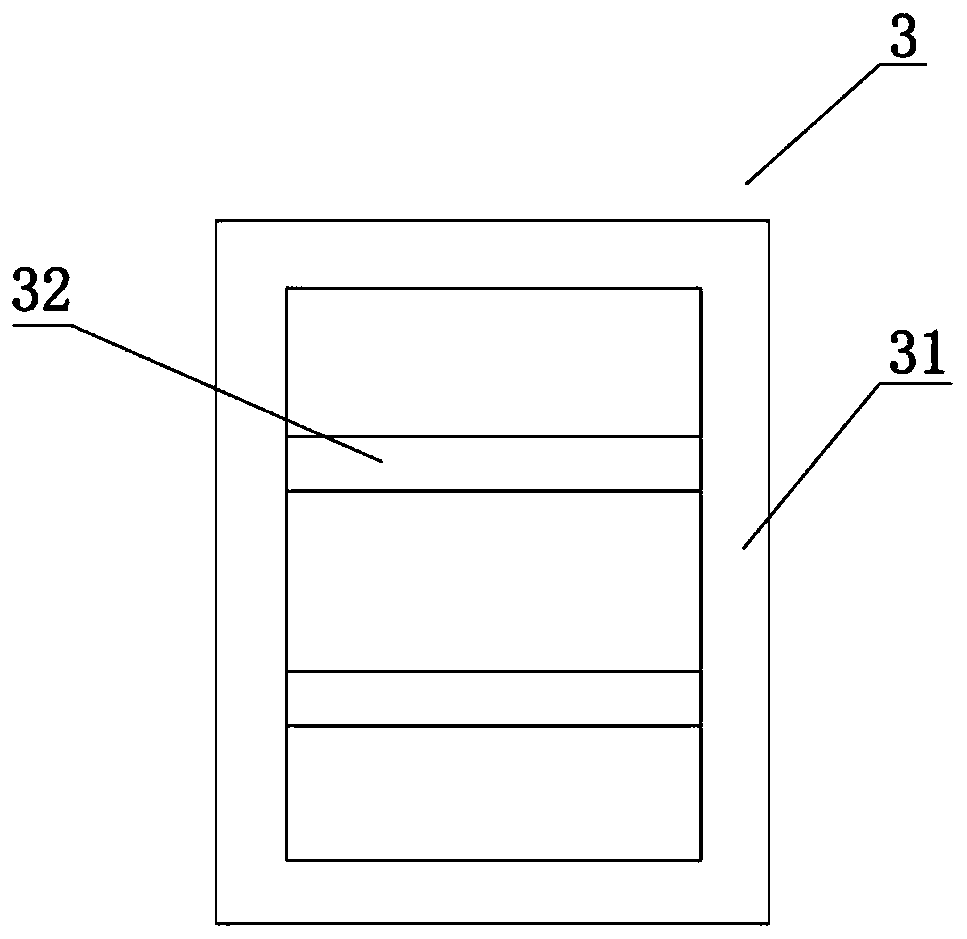

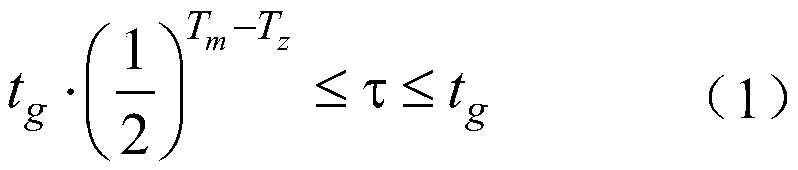

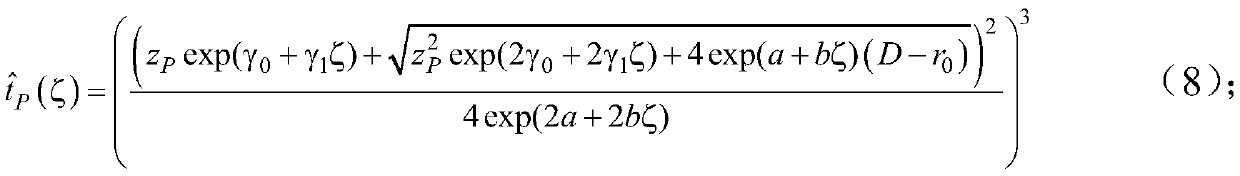

Optimization method of degeneration acceleration test scheme of electric connector

ActiveCN108132395AReliable optimization resultsImprove estimation accuracyEnvironmental/reliability testsElectricityWorking life

The invention discloses an optimization method of a degeneration acceleration test scheme of an electric connector. The sample size used in a stress-constant degeneration acceleration test and the distribution ratio of samples in different tests influence a test result. The method comprises the concrete steps that 1) the working life tg, the storage environment temperature T0, the lowest test temperature Tz, the highest test temperature Tm and the cutoff time tau of the electric connector are determined; 2) a random process degeneration model of median life of the electric connector is established; 3) m electric connectors to be detected are taken for primary test to obtain parameters a, b, gamma0 and gamma 1 to be evaluated; 4) an optimized target function is determined; and 5) the test temperature and sample distribution ratio of each test are determined. According to the optimization method, the sample distribution ratio of each test is optimized, and the storage life is estimated in higher precision compared with a traditional test scheme in which samples are distributed equivalently under the same total sample size, the same cutoff time, and the same test interval.

Owner:ZHEJIANG SCI-TECH UNIV

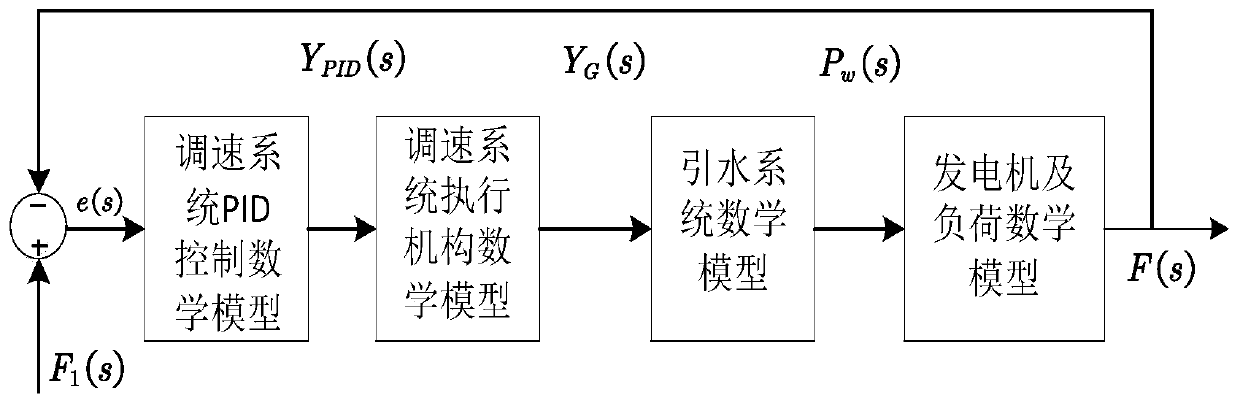

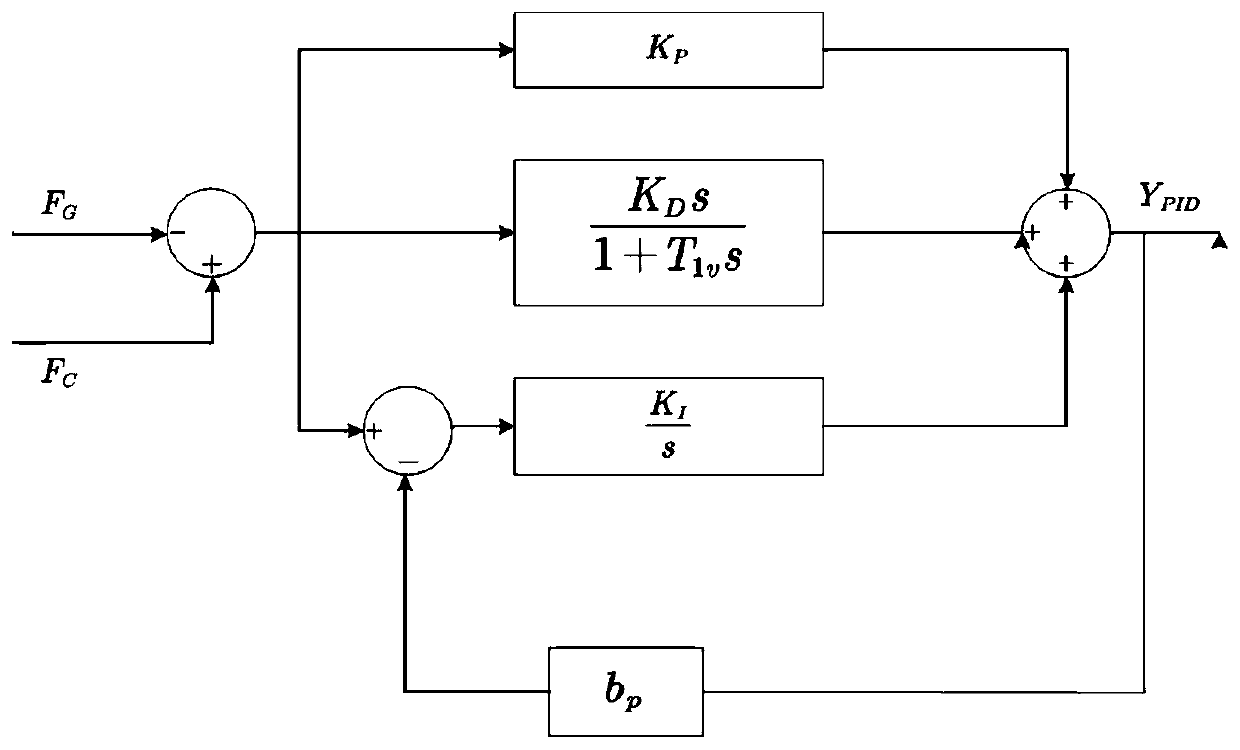

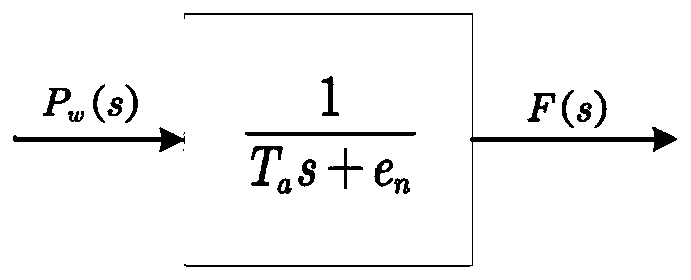

Method for optimizing air-borne PID parameters of mixed-flow hydro-generator governor

PendingCN110778447AGuaranteed stabilityClear expressionData processing applicationsHydro energy generationMathematical modelControl engineering

The embodiment of the invention provides a method for optimizing air-borne PID parameters of a mixed-flow hydro-generator governor, and relates to the technical field of intelligent optimization control. The method comprises the following steps that an initialization population is randomly generated, an initial temperature T0 and a final temperature T1 are determined, and the initialization population comprises a plurality of sets of PID parameters; the population is subjected to iterative optimization by using an improved teaching and learning algorithm; and a set of PID parameters with the minimum evaluation index are selected from the population which is subjected to the iterative optimization to be an optimal PID parameter. According to the method for optimizing the air-borne PID parameters of the mixed-flow hydro-generator governor, an air-borne PID disturbance mathematical model and an ITLBO optimization method of a mixed-flow hydro-generator speed regulation system are provided,so that the expression of the PID parameter optimization process is clearer, the optimization result is more trusted, and after the optimized PID parameters are used, the stability of a hydro-generator unit in the operation process is facilitated.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

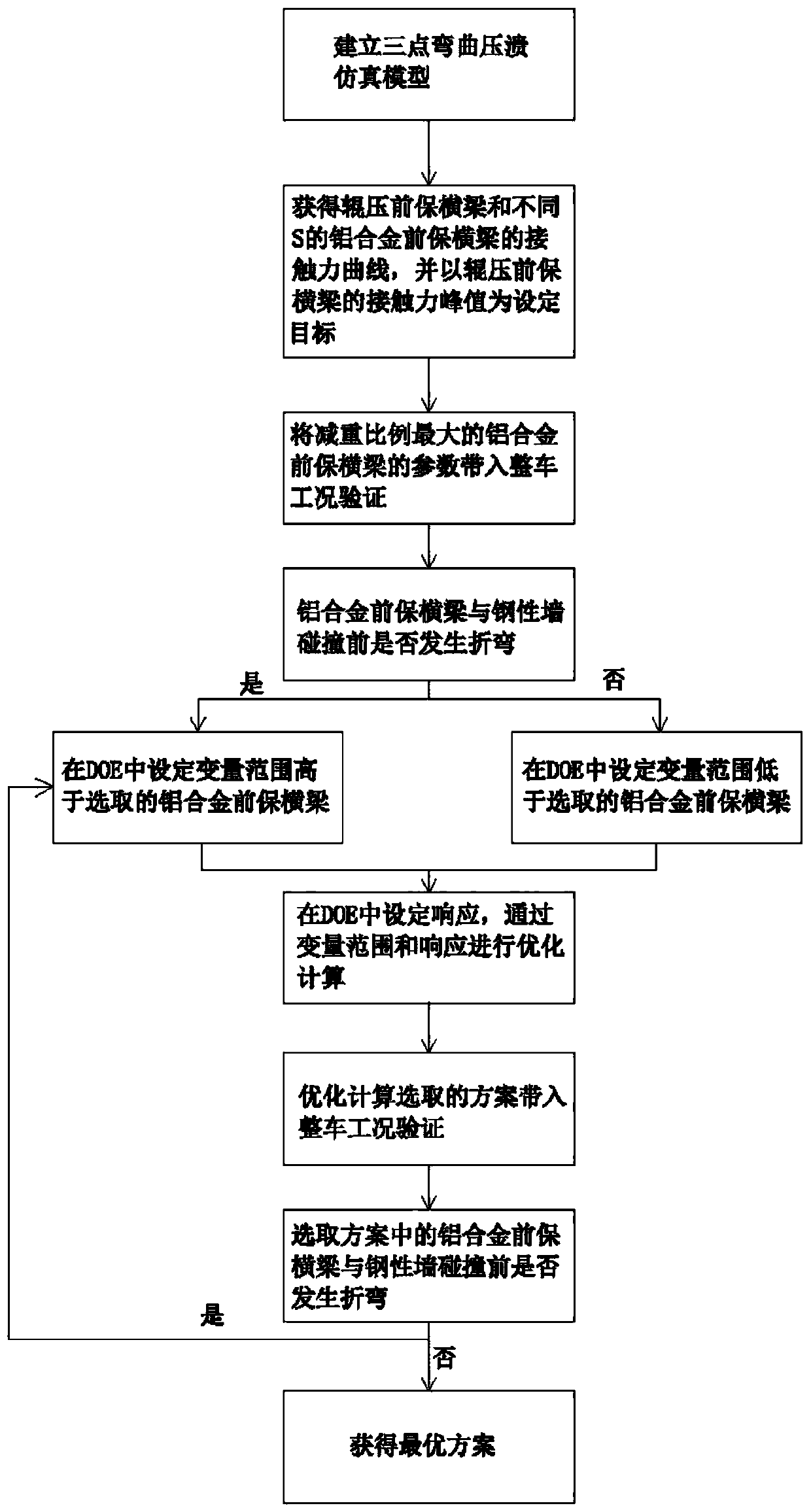

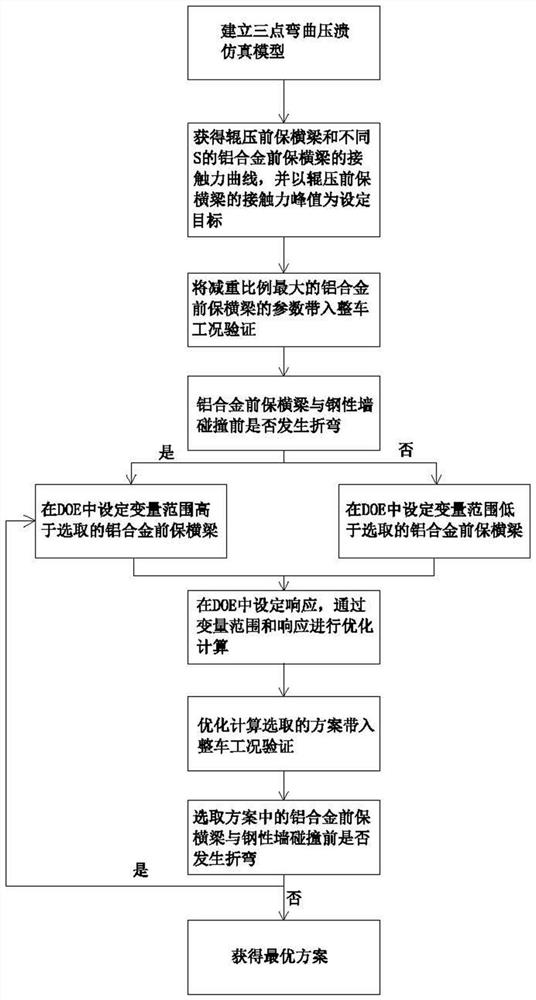

DOE-based optimization method for anti-collision performance of front bumper beam of automobile

ActiveCN110941903AImprove reliabilityStrong data supportGeometric CADDesign optimisation/simulationStructural engineeringMechanical engineering

The invention discloses a DOE-based optimization method for the anti-collision performance of a front bumper beam of an automobile. The invention belongs to the technical field of automobile front bumper beam structure design. The optimization method comprises the following steps: establishing a three-point bending crushing model; obtaining contact force curves of the two kinds of front bumper crossbeams and taking a contact force peak value of rolling the front bumper crossbeams as a target; the aluminum alloy front bumper beam with the maximum weight reduction proportion is brought into thewhole vehicle working condition to be verified; setting a variable range and response and optimizing calculation; substituting the scheme selected by the optimization calculation into the whole vehicle working condition verification to obtain an optimal scheme; the invention has the following beneficial effects. According to the optimization method, a simulation model is compared with a test model; simulation model is optimized, according to the method, multiple sets of variables and responses are subjected to optimization calculation, the obtained scheme is repeatedly verified, the optimal scheme is finally obtained, the efficiency of model building and optimization calculation is high, the obtained optimization result of the front bumper beam is more reliable, powerful data support is provided for production design of the front bumper beam, and the product development cost of an enterprise is saved.

Owner:CHERY AUTOMOBILE CO LTD

A Method for Optimizing the Accelerated Degradation Test Scheme of Electrical Connectors

ActiveCN108132395BReliable optimization resultsImprove estimation accuracyEnvironmental/reliability testsWorking lifeElectrical connection

Owner:ZHEJIANG SCI-TECH UNIV

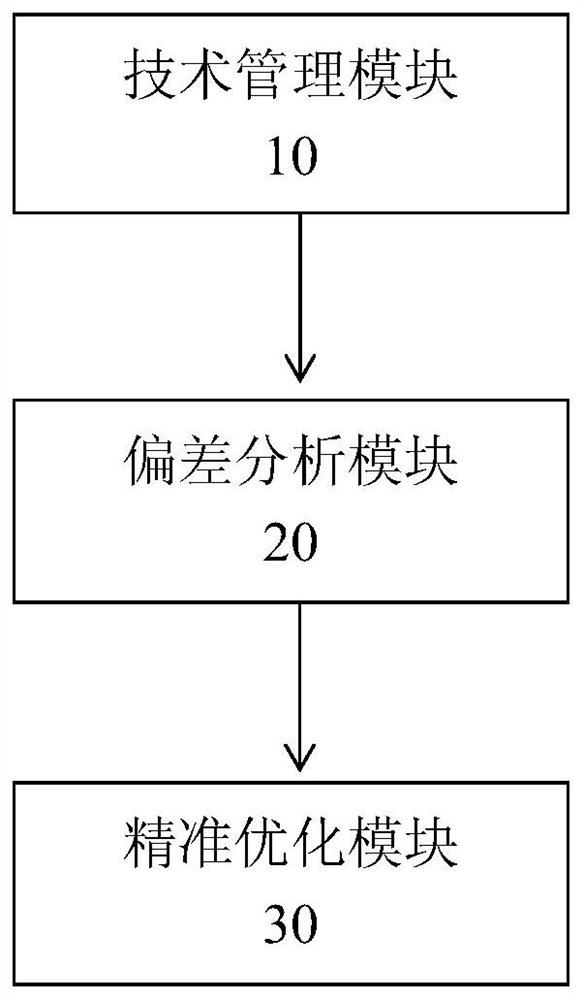

Wind power plant system optimization system based on front, middle and later period data of wind power plant

PendingCN113268851AClear thinkingReliable optimization resultsData processing applicationsDesign optimisation/simulationControl engineeringEngineering

The invention relates to a wind power plant system optimization system based on front, middle and later data of a wind power plant, and the system comprises: a technical management module which is used for the early data management of the wind power plant, the engineering data management of the wind power plant, and the operation data management of the wind power plant; a deviation analysis module which is used for evaluating potential optimizable fans in the wind power plant through multi-dimensional deviation analysis, and checking and positioning potential optimizable fan units based on a wind power plant operation evaluation analysis result, early-stage wind power plant design data and fan real-time operation data; and a precise optimization module which is used for carrying out system optimization on the potential optimizable fan unit through optimization models and tools of different levels, obtaining an optimization effect in real time and providing precise support for a wind power plant production operation optimization decision. According to the method, the optimization process and thought can be clearer, the optimization result is more reliable, and optimization management is more powerful; the optimization scheme is guaranteed to be based on the basis and can be implemented and reproduced; and comparison of different optimization schemes is facilitated.

Owner:中国大唐集团新能源科学技术研究院有限公司

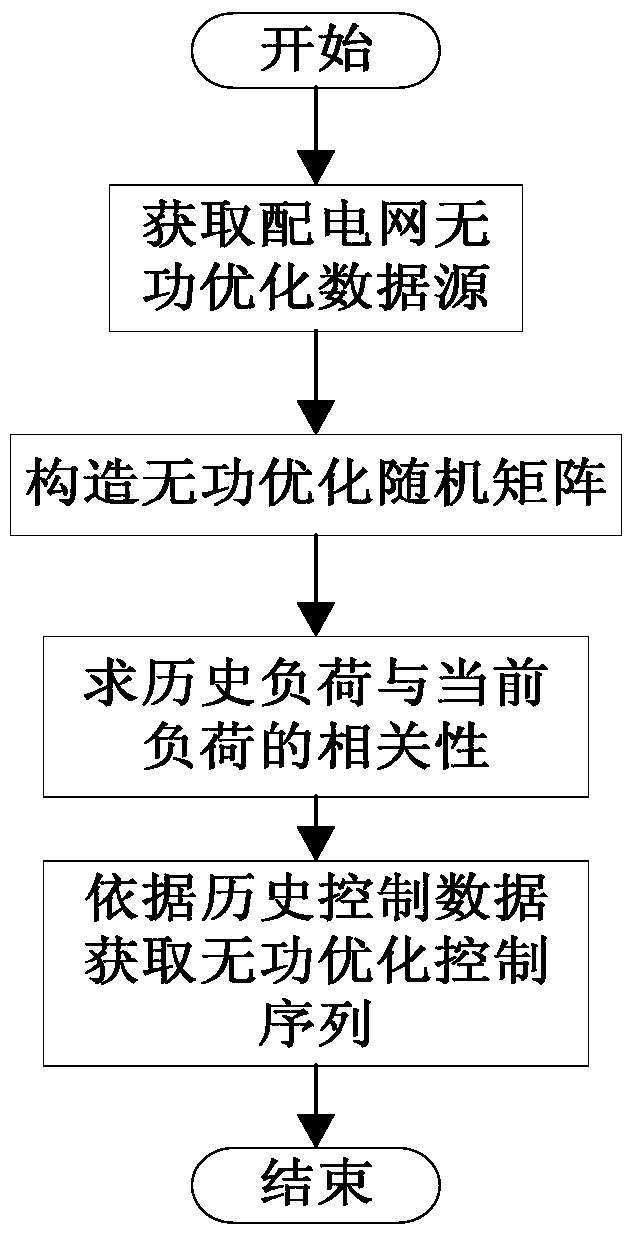

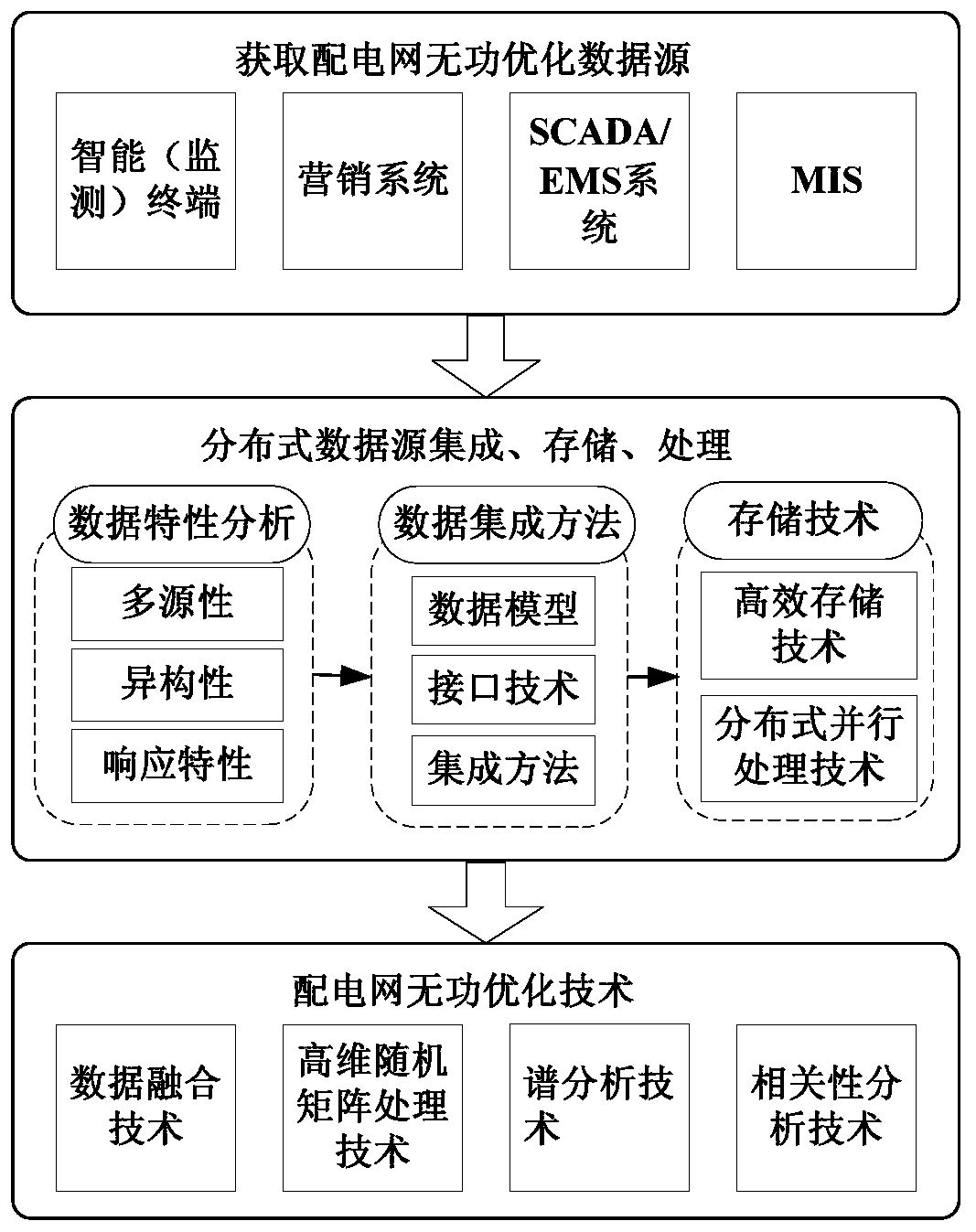

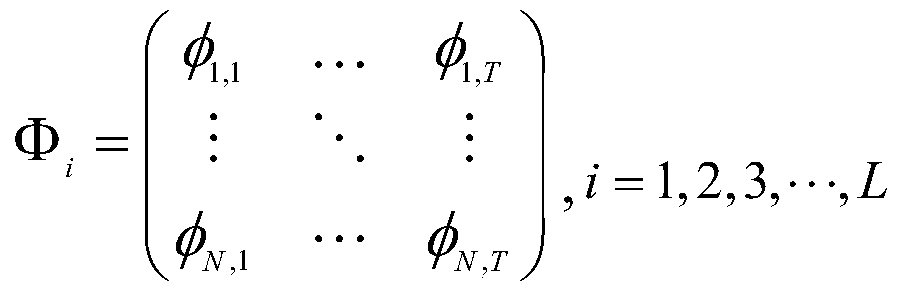

A method for determining reactive power optimization control sequence of distribution network based on big data

ActiveCN107134790BSolving Reactive Power Operation Optimization ProblemsImprove securityLoad forecast in ac networkReactive power adjustment/elimination/compensationElectric power systemOperations research

Owner:CHINA ELECTRIC POWER RES INST +2

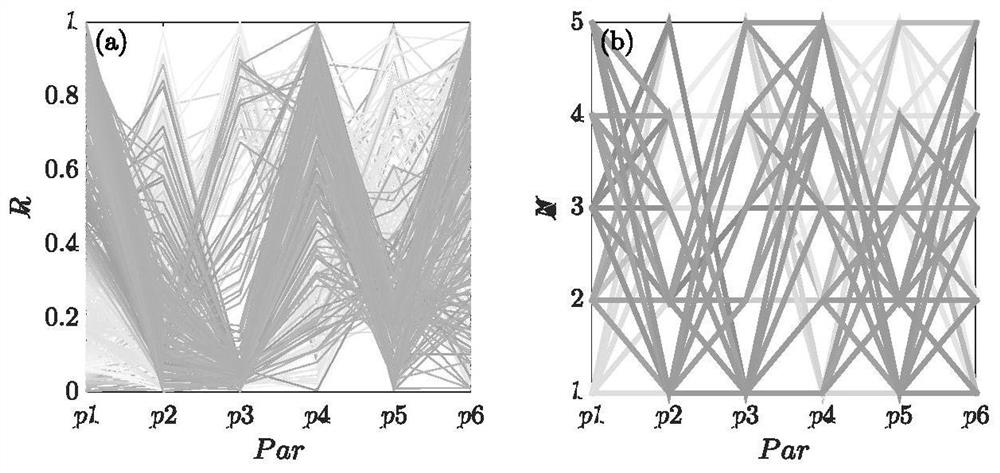

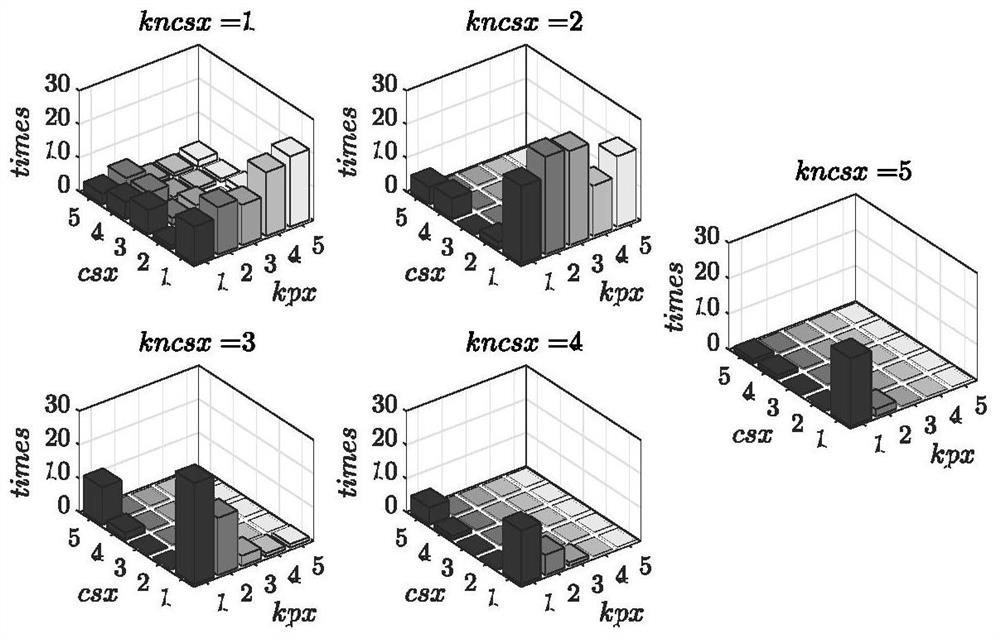

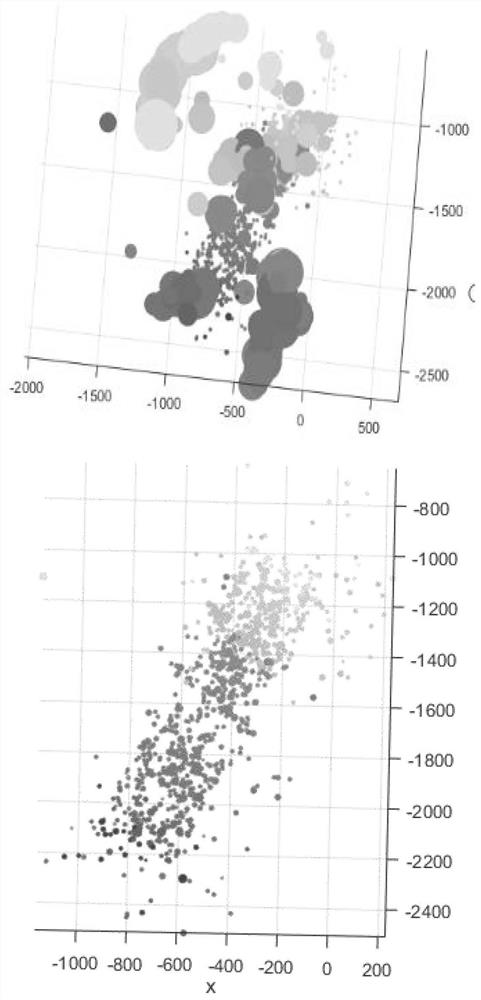

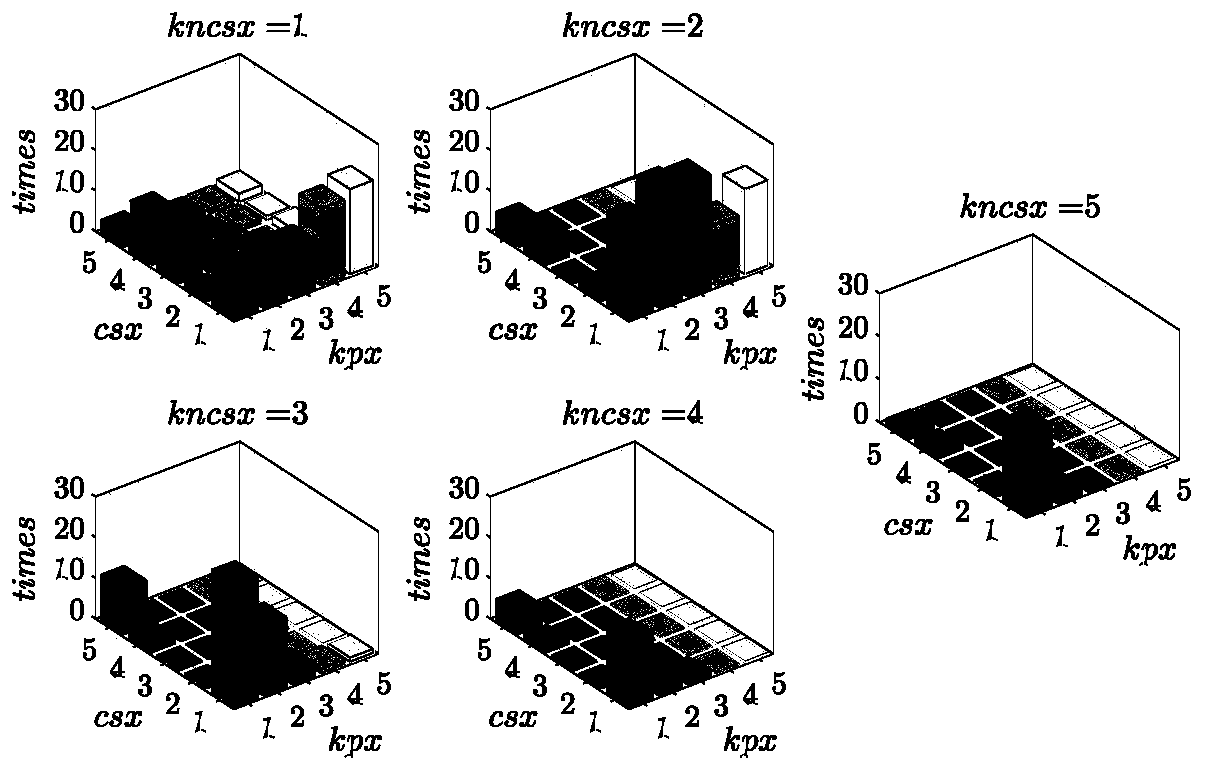

A Method for Optimal Matching of Bogie Suspension Parameters

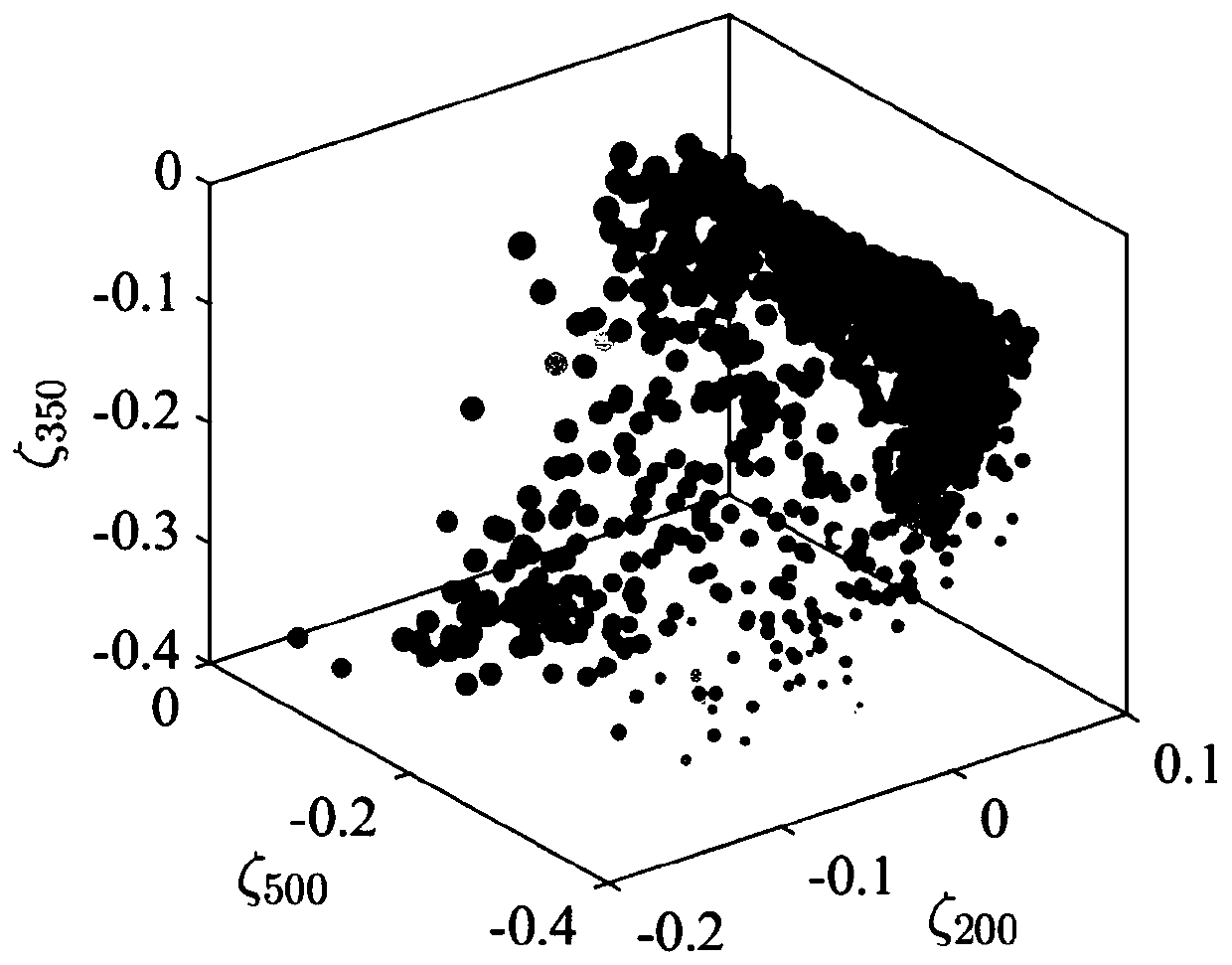

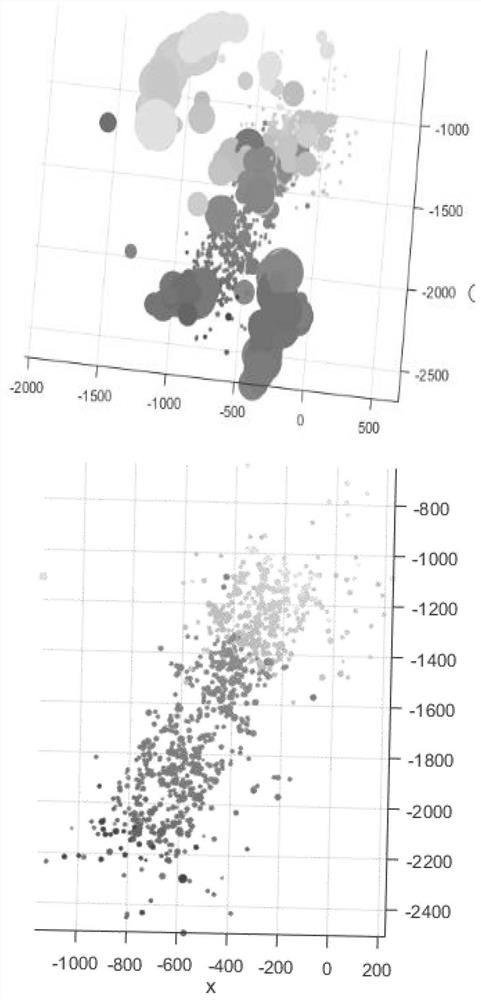

ActiveCN109918836BReliable Suspension Parameter Optimization ResultsReliable optimization resultsGeometric CADDesign optimisation/simulationVehicle dynamicsBogie

The invention provides a bogie suspension parameter optimization matching method, which relates to the technical field of suspension parameter optimization design of rolling stock. Establish vehicle dynamics simulation model; carry out suspension parameter matching optimization analysis, determine the input variables and their value ranges required by the model, output evaluation indicators and their threshold settings, and establish a joint simulation module between vehicle dynamics model simulation and MATLAB, According to the optimization goal, the eigenvalue simulation calculation of the vehicle dynamics model is carried out, and the optimization goal value obtained by the simulation is extracted through the co-simulation interface; the required suspension parameter group is obtained from a large number of random parameters by layer-by-layer screening, Finally, the method of discrete statistics is used to process the optimization result data, combining the three-dimensional histogram to mine the matching relationship between the suspension parameters, and according to the actual needs, select the specific value of the matching combination of suspension parameters that meet the requirements and the corresponding optimization target value .

Owner:SOUTHWEST JIAOTONG UNIV

A doe-based optimization method for the anti-collision performance of automobile front bumper

ActiveCN110941903BImprove reliabilityStrong data supportGeometric CADDesign optimisation/simulationMechanical engineeringIndustrial engineering

A DOE-based optimization method for the anti-collision performance of the front bumper of the automobile belongs to the technical field of the structural design of the front bumper of the automobile. The peak value of the contact force of the roll-pressed front bumper is taken as the target, and the aluminum alloy front bumper with the largest weight reduction ratio is brought into the vehicle working condition for verification, the variable range and response are set and the optimization calculation is carried out. The optimal solution is obtained from the verification of the working conditions of the whole vehicle. The beneficial effect of the present invention is that the optimization method compares the simulation model with the test model, optimizes the simulation model, performs optimization calculations on multiple groups of variables and responses, and obtains the solution After repeated verification, the optimal solution is finally obtained. The efficiency of model establishment and optimization calculation is high, and the optimization result of the front beam is more reliable, which provides strong data support for the production design of the front beam and saves the company's product development. cost.

Owner:CHERY AUTOMOBILE CO LTD

A hydraulic fracturing design parameter optimization method based on fine reservoir classification

ActiveCN105003240BReliable optimization resultsRealisticFluid removalHydraulic fracturingEngineering

Owner:SOUTHWEST PETROLEUM UNIV +1

A high-precision vehicle steering gear bracket and its manufacturing method

ActiveCN106114610BPrevent looseningMeet the mechanical requirementsGeometric CADSpecial data processing applicationsDie castingMechanical engineering

The invention discloses a high-precision automobile steering gear bracket and a manufacturing method thereof. The steering gear bracket comprises a fixing base, a mounting base and a connecting plate, wherein a rotary table is mounted in the fixing base; locking screw rods are connected to the rotary table; a U-shaped connecting piece and screw holes are connected to the side surface of the mounting base; a mounting groove is formed in the U-shaped connecting piece; a hydraulic oil cylinder is arranged in the connecting plate; a piston rod is connected to the hydraulic oil cylinder; and a press block is connected to the piston rod. The manufacturing method of the steering gear bracket comprises the following steps of (1) designing the structure of the steering gear bracket; (2) performing sample test; (3) performing simulated die-casting on the steering gear bracket; (4) performing simulated die-casting; and (5) performing die-casting of the steering gear bracket. Compared with the prior art, mechanical analysis of models and mechanical test of real objects are respectively performed on the steering gear bracket disclosed by the invention, so that mechanical defects of a conventional steering gear bracket are thoroughly rejected, all the mechanical requirements are met, the quality of products is improved, and the steering gear bracket disclosed by the invention has tremendous potential economic value.

Owner:XINCHANG XINCHAI MACHINERY CO LTD

A fracturing optimization method for deep shale gas reservoirs based on fracability evaluation

ActiveCN113312785BComprehensive Compressibility CharacterizationReliable optimization resultsFluid removalDesign optimisation/simulationShale gasGeophysics

The invention discloses a deep shale gas reservoir fracturing optimization method based on fracability evaluation, which includes: obtaining geological parameters, establishing a three-dimensional geological model; performing grid division on the geological model and calculating the fracturing of all geological grids respectively Comprehensive fracturing index; according to the comprehensive fracturing index, all geological grids are divided into three levels and the geological grids of the same level are classified into the same level of fracturing section; for each level of fracturing The production simulation is carried out under the conditions of fixed fluid intensity and different sanding intensity, and the construction curves of different stages are obtained. The highest inflection point of the curve is the optimal fracturing design parameter; According to the calculated stages, directly select the optimal fracturing design parameters of this stage determined in the previous step as the optimal parameters for construction. The present invention obtains a more comprehensive characterization of the fracturability of the fracturing interval, and conducts more precise fracturing design parameter optimization for each fracturing well section, so that the optimization result is more reliable and has practical significance.

Owner:SOUTHWEST PETROLEUM UNIV

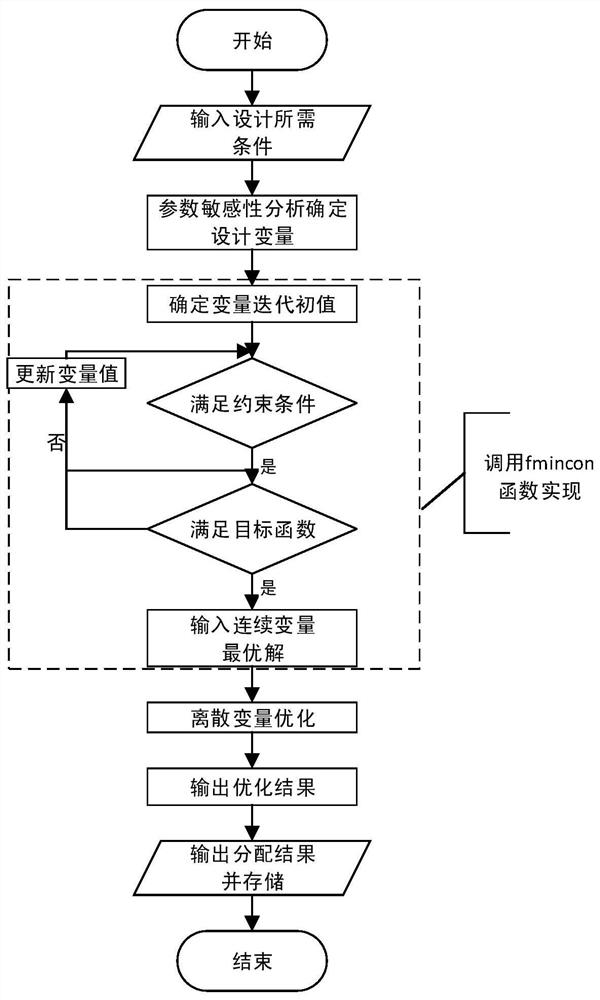

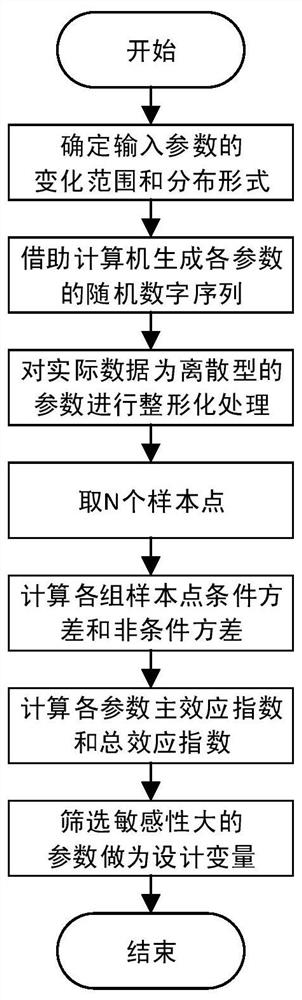

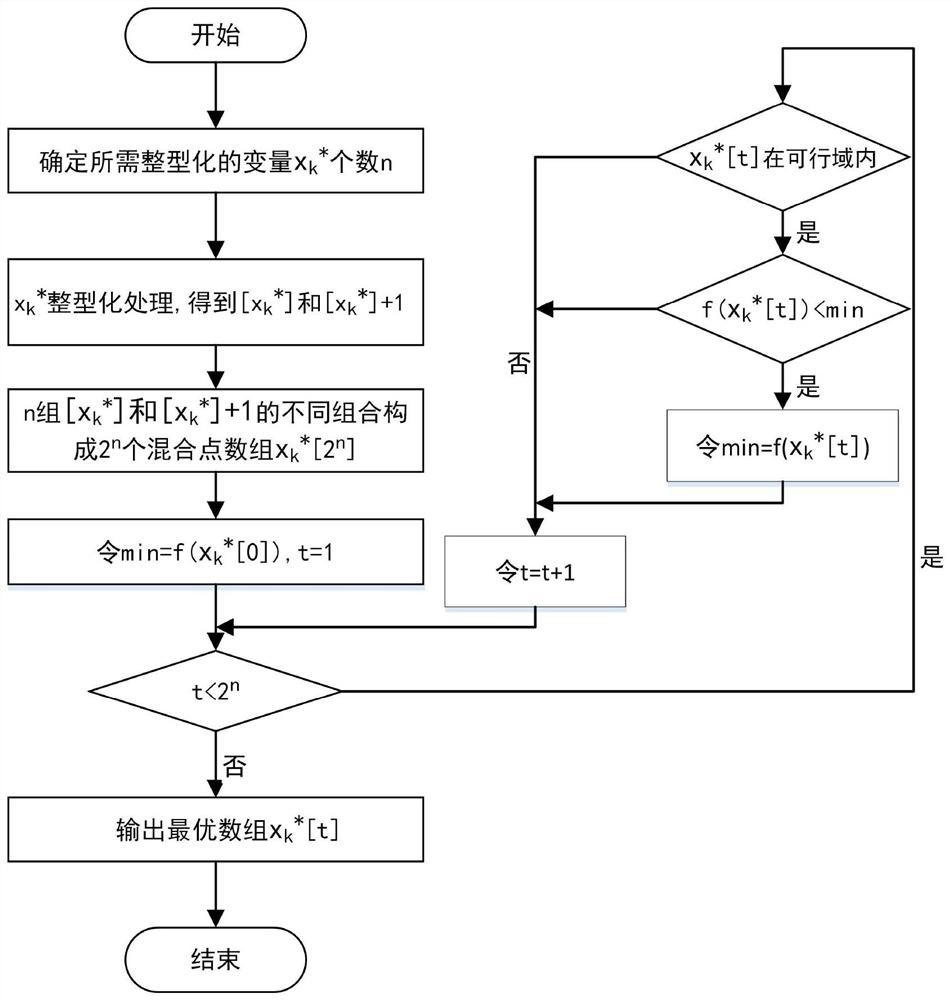

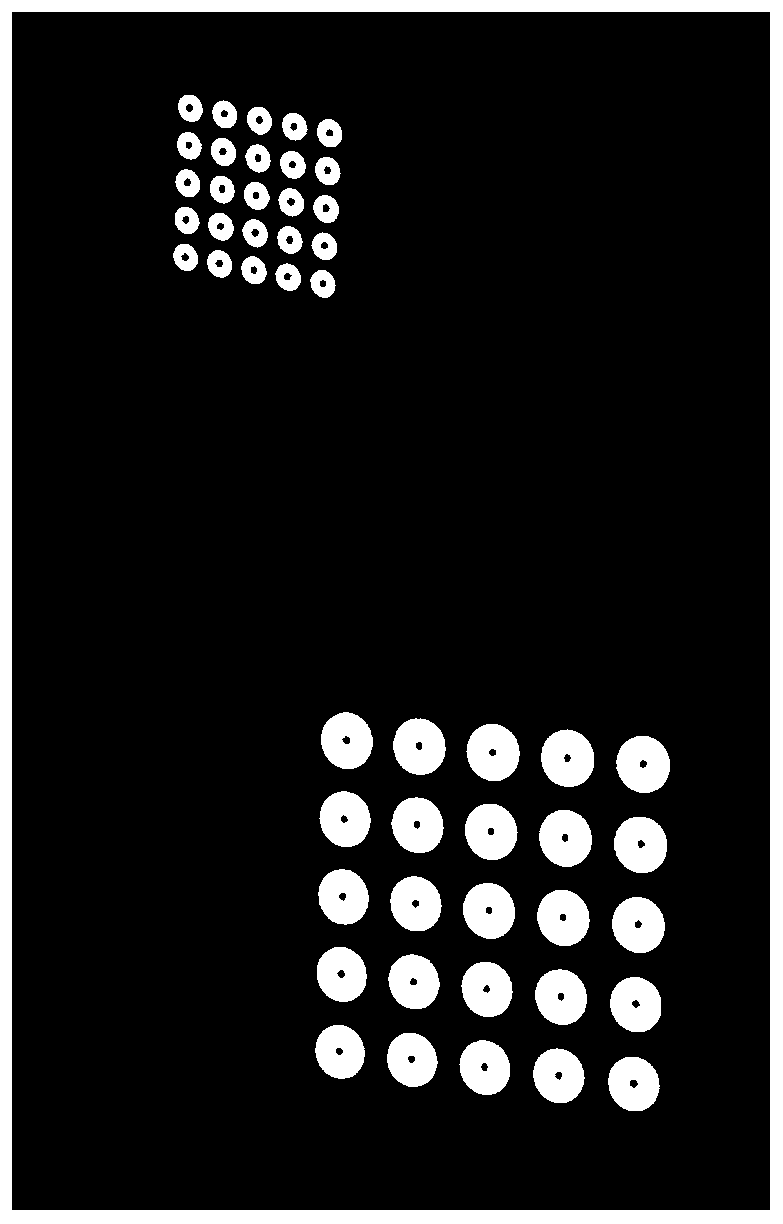

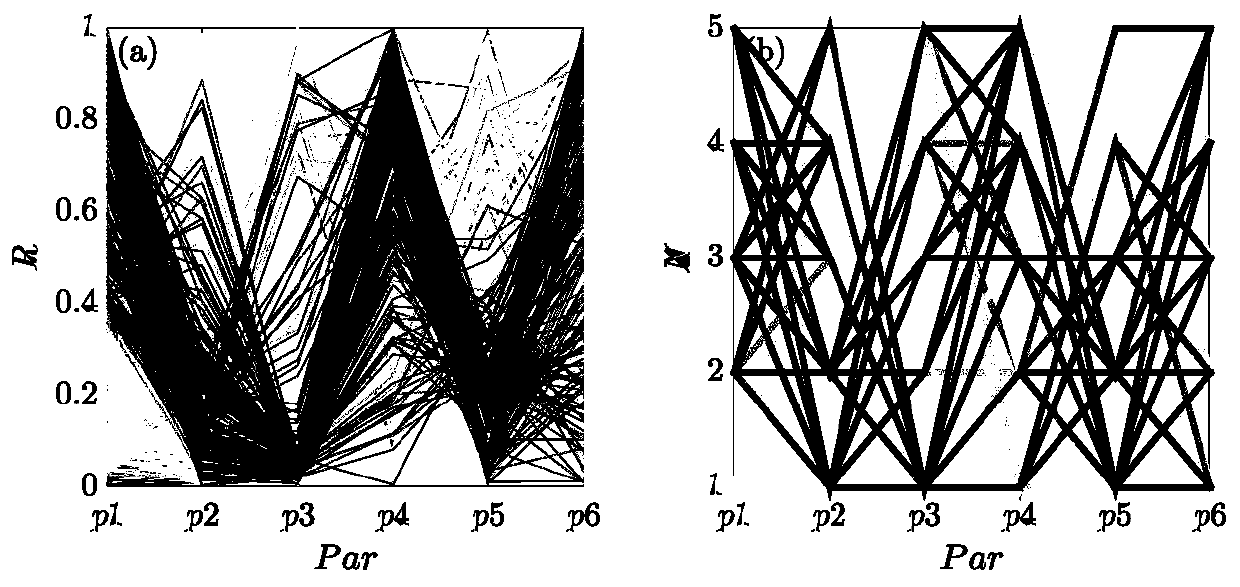

Improved transmission ratio distribution method for multistage cylindrical gear transmission system

PendingCN114036672AImprove design efficiencyThe method is accurate and reasonableGeometric CADDesign optimisation/simulationGear driveSensitive analysis

The invention aims to provide an improved transmission ratio distribution method for a multistage cylindrical gear transmission system. The method comprises the following steps: determining working conditions; determining a target function; determining a change range and a distribution form of each input parameter, and performing shaping processing on discrete data; analyzing the sensitivity of each input parameter by using a global sensitivity analysis method based on variance, determining a design variable, and simplifying the required input parameters; determining constraint conditions; substituting the established optimization model into a sequential quadratic programming algorithm, and outputting an optimized continuous solution; and optimizing continuous solution integer discrete processing on output which is actually discrete data to obtain a plurality of groups of mixed discrete variables, screening out an optimal result and outputting the optimal result. According to the method, transmission ratio distribution of the cylindrical gear system of any stage can be carried out, and compared with an existing second-stage transmission ratio distribution method, a third-stage transmission ratio distribution method and other few-stage transmission ratio distribution methods, the design efficiency of the cylindrical gear transmission system is greatly improved.

Owner:中国船舶重工集团公司第七0三研究所 +1

A Spatial Position and Attitude Calculation Method for Overall Target Optimization

ActiveCN107576286BReasonable and accurate spatial postureConducive to solutionUsing optical meansBack projectionBack calculation

The invention discloses a spatial position and posture solving method based on integral target optimization, and belongs to the field of production, maintenance and service of vehicles. According to the spatial position and posture solving method based on integral target optimization, imaging of targets in different states can be taken as imaging of a same target on cameras, the cameras in different states can be used for shooting the targets at different spatial positions, known spatial points are projected into the cameras for imaging according to the related principle of three-dimensional reconstruction, constraint is done based on minimum back projection, least square solving is performed to acquire the positions of the cameras, the cameras (corresponding to large target extraction errors caused by factors such as shaking during movement) with large residual errors are eliminated, and accurate postures and positions of the targets are acquired through back calculation.

Owner:安徽省爱夫卡电子科技有限公司

Bogie suspension parameter optimization matching method

ActiveCN109918836ASimple designImprove analytical performanceSpecial data processing applicationsVehicle dynamicsBogie

The invention provides a bogie suspension parameter optimization matching method, and relates to the technical field of suspension parameter optimization design of rolling stock. The method comprisesthe following steps of establishing a vehicle dynamics simulation model; carrying out suspension parameter matching optimization analysis; determining an input variable required by the model, a valuerange of the input variable, an output evaluation index and threshold setting of the output evaluation index; establishing a joint simulation module for vehicle dynamics model simulation and MATLAB, conducting characteristic value simulation calculation on a vehicle dynamics model according to an optimization target, and extracting an optimization target value obtained through simulation of the vehicle dynamics model through a joint simulation interface; acquiring a required suspension parameter set from a large number of random parameters in a layer-by-layer screening manner; and finally, processing the optimization result data by adopting a discrete statistical method, mining a matching relationship among the suspension parameters by combining a three-dimensional histogram, and selectingparameter specific values of suspension parameter matching combinations meeting requirements and corresponding optimization target values according to actual requirements.

Owner:SOUTHWEST JIAOTONG UNIV

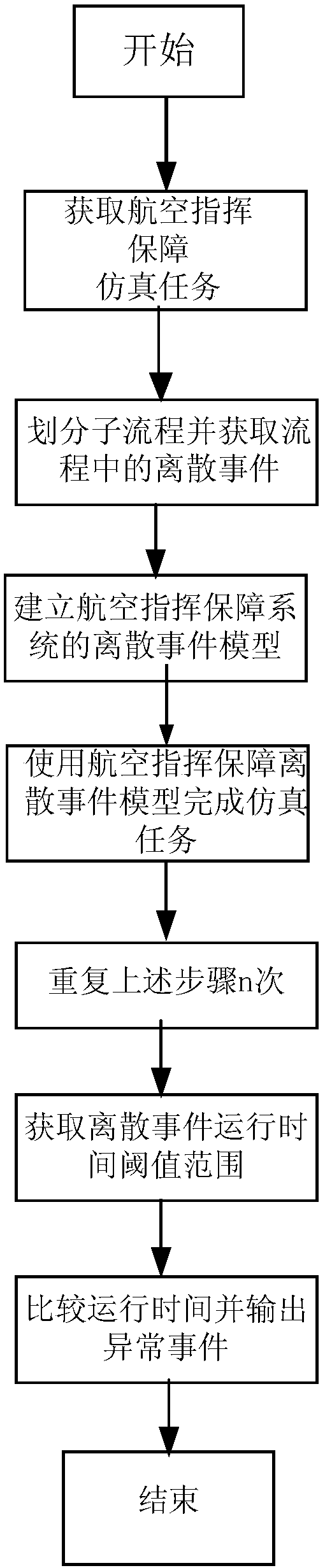

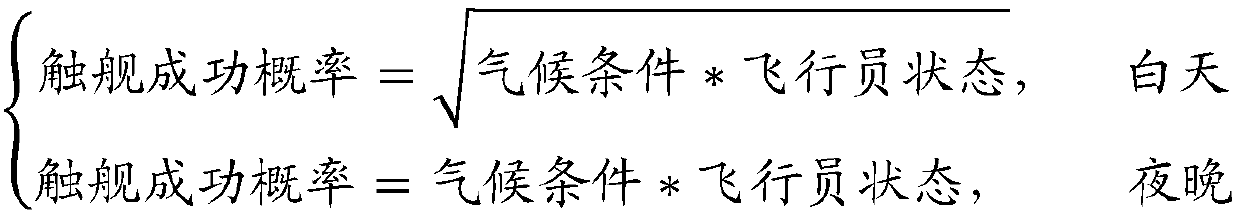

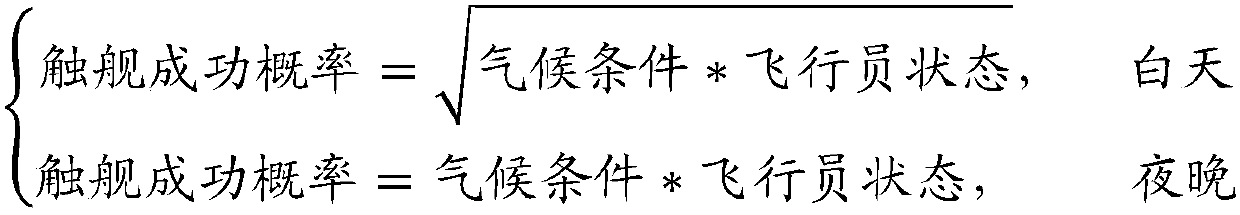

An Optimization Method of Aviation Command Support Based on Discrete Event System

ActiveCN105825013BAviation command and support process is clearImplement Impact AnalysisSpecial data processing applicationsAviationEvent model

Owner:CSSC SYST ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com