Gas-liquid separator for multi-connected heat pump and manufacturing method of gas-liquid separator

A gas-liquid separator, gas-liquid separation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of incomplete removal of liquid droplets, low separation efficiency, short service life, etc., and achieve fast molding speed , long flow time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

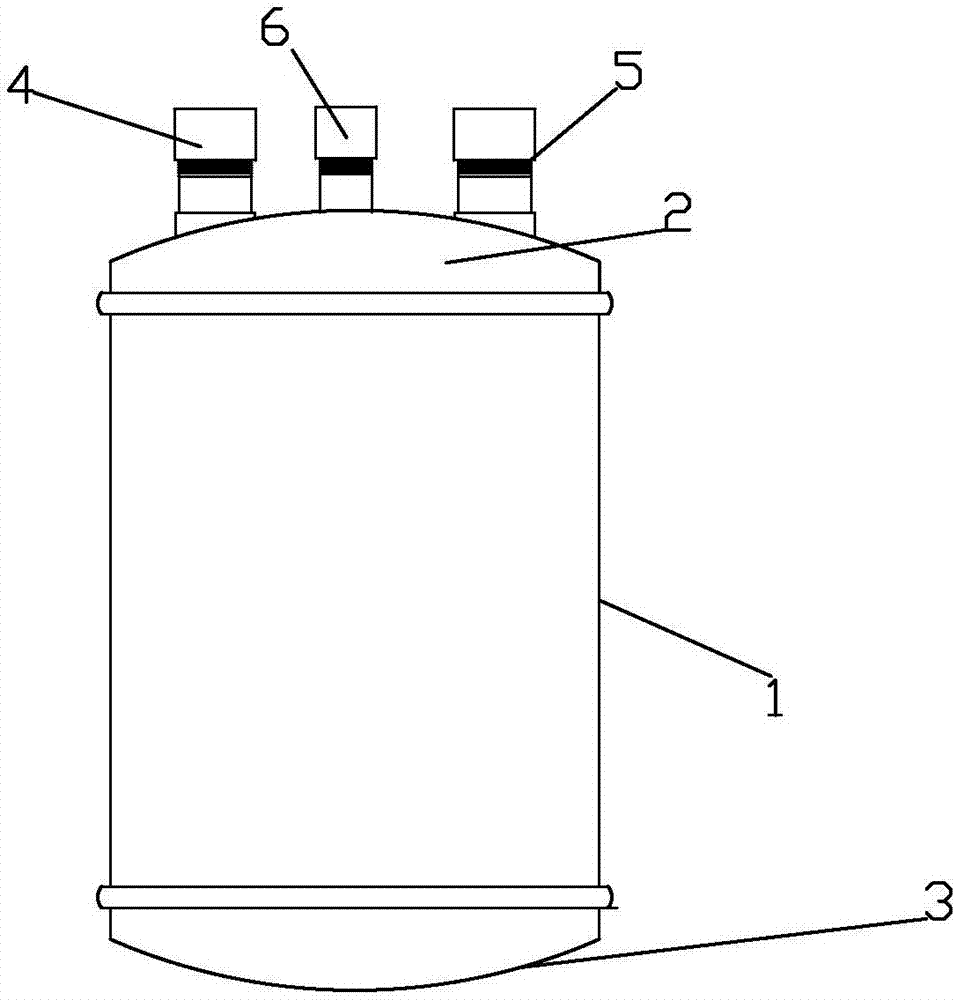

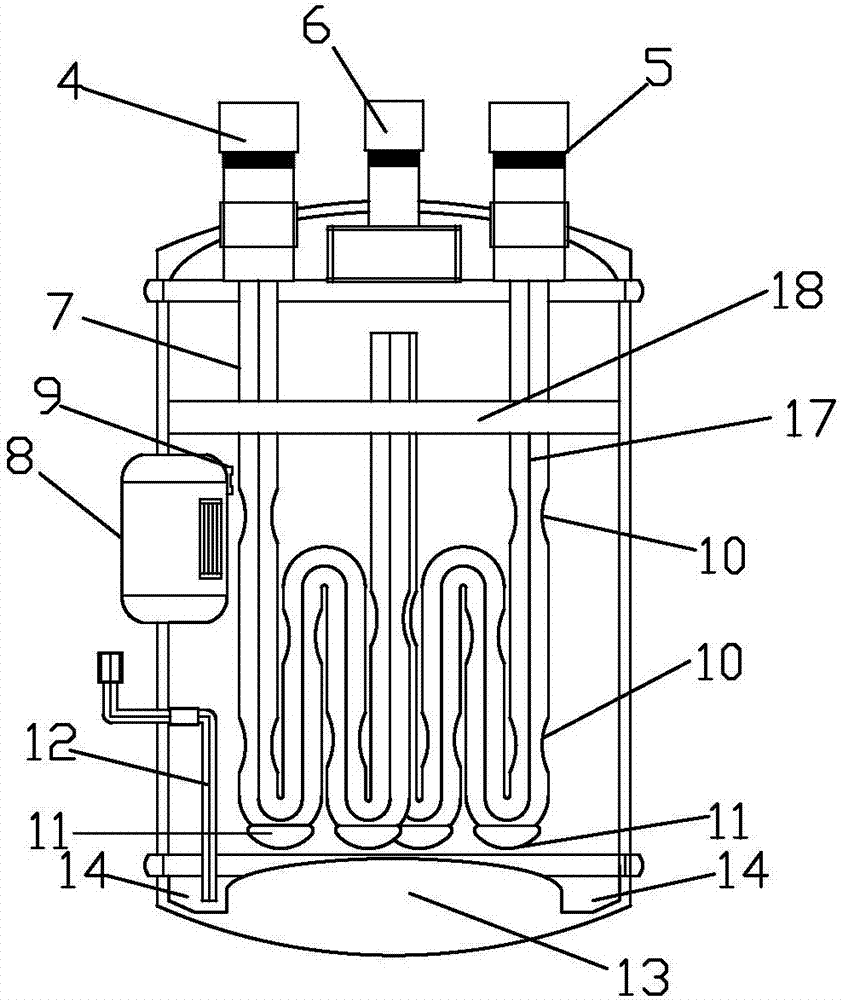

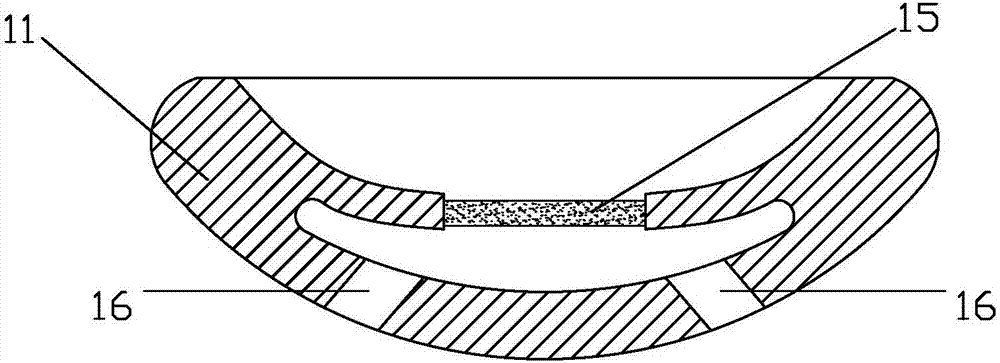

[0042] Such as Figure 1 to Figure 6 As shown, a gas-liquid separator for a multi-connected heat pump includes a cylinder body 1, an air inlet pipe, an air outlet pipe 6 and a liquid outlet pipe 12, the upper part of the cylinder body 1 is an upper end cover 2, and the lower part of the cylinder body 1 is a lower end cover 3; Both the air pipe and the air outlet pipe 6 are arranged on the upper end cover 2, and the air inlet pipe includes a first air inlet pipe 4 and a second air inlet pipe 5, the first air inlet pipe 4 and the second air inlet pipe 5 are identical, and both are used to guide the gas-liquid mixture; The gas-liquid separator adopts double inlet pipes, which can separate more gas-liquid mixtures at the same time, and the work efficiency is significantly improved; and the number of inlet pipes to be put into use can be selected according to the actual working conditions, which is adjustable and has a wider scope of application. wide.

[0043] A gas-liquid separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com