A method for preparing modified composite HF-TA metal coating by laser cladding

A technology of laser cladding and metal coating, which is applied in the direction of metal material coating technology, coating, metal processing equipment, etc., can solve the problems of inability to effectively block oxygen diffusion, poor bonding force, peeling, etc., and avoid the use of target materials Effects of low efficiency, reduced influence, and fast coating forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

[0030] Step 1, pickling the surface of the refractory metal after grinding, and then performing sandblasting and degreasing treatment on the surface of the refractory metal after pickling; the sand used in the sandblasting is corundum sand, and the sandblasting The pressure is 0.4MPa; the refractory metal is a Ta10W alloy; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 7:3, and the mass concentration of the hydrofluoric acid is 50 %, the mass concentration of the concentrated nitric acid is 67%; preferably, the refractory metal is immersed in acetone for degreasing treatment;

[0031] Step 2: Put the mixed powder and dispersant in a ball mill and mix them uniformly to obtain a modified composite Hf-Ta slurry; the mixed powder is uniformly mixed with tantalum powder, hafnium powder and modified metal powder, and the mixed The mass percent composi...

Embodiment 2

[0036] This example is the same as Example 1, except that the modified metal powder in step 2 is one, two or more of silicon powder, boron powder, aluminum powder, chromium powder and iron powder , or a mixture of one of boron powder, aluminum powder, chromium powder and silicon powder, iron powder, or a mixture of two of boron powder, aluminum powder, chromium powder and one of silicon powder, iron powder.

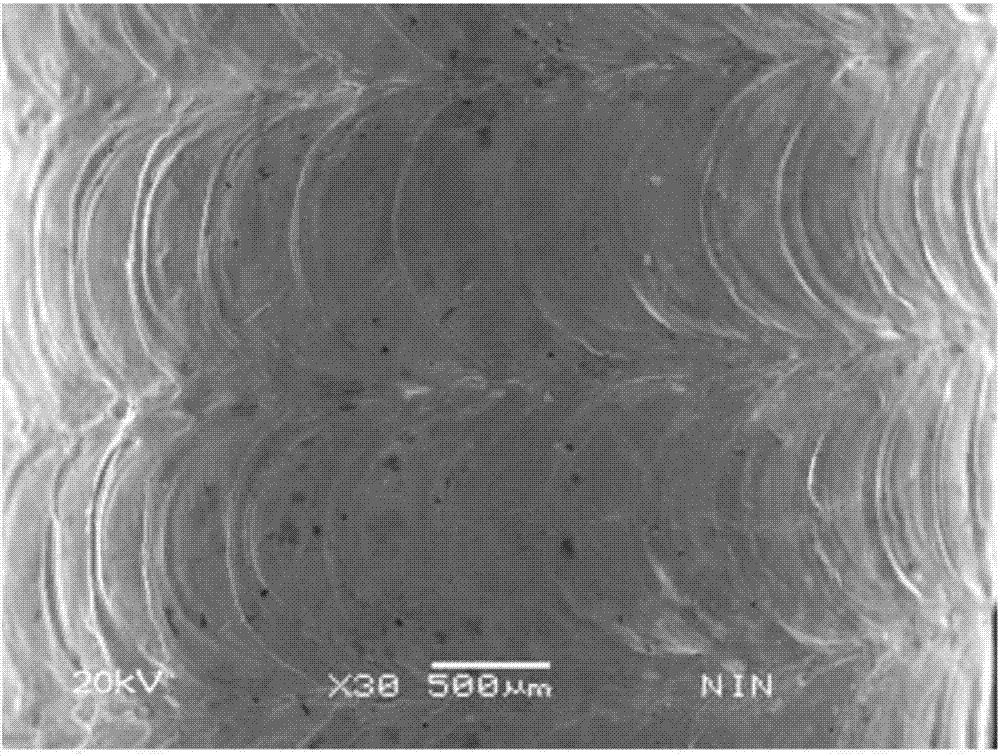

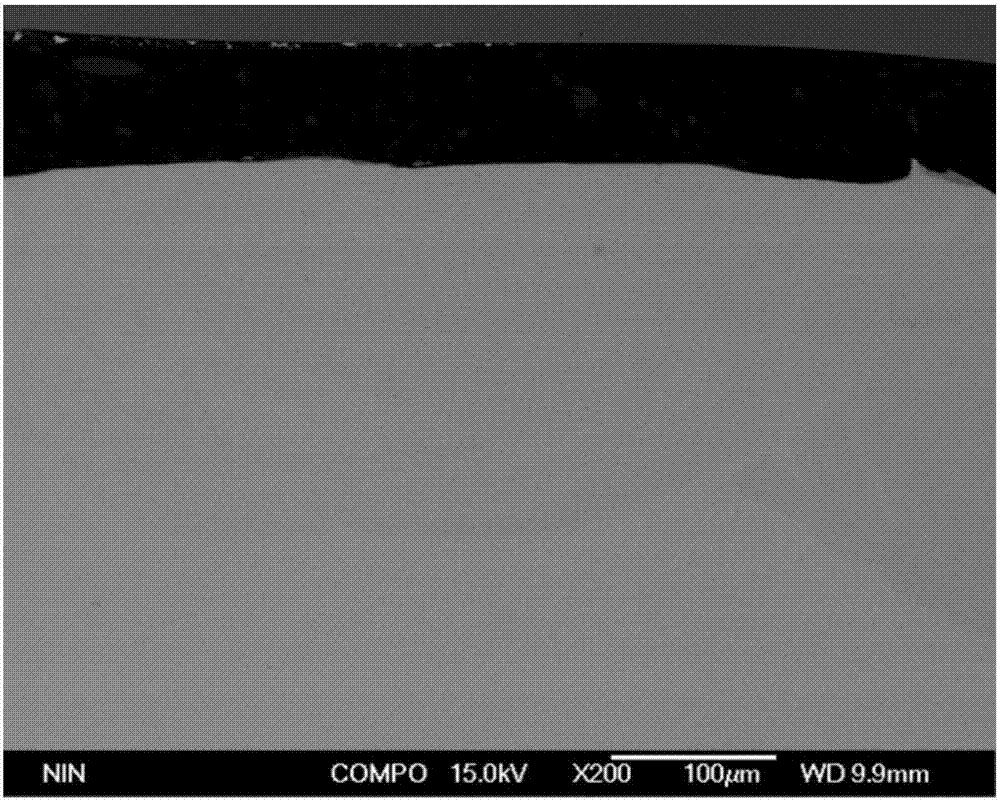

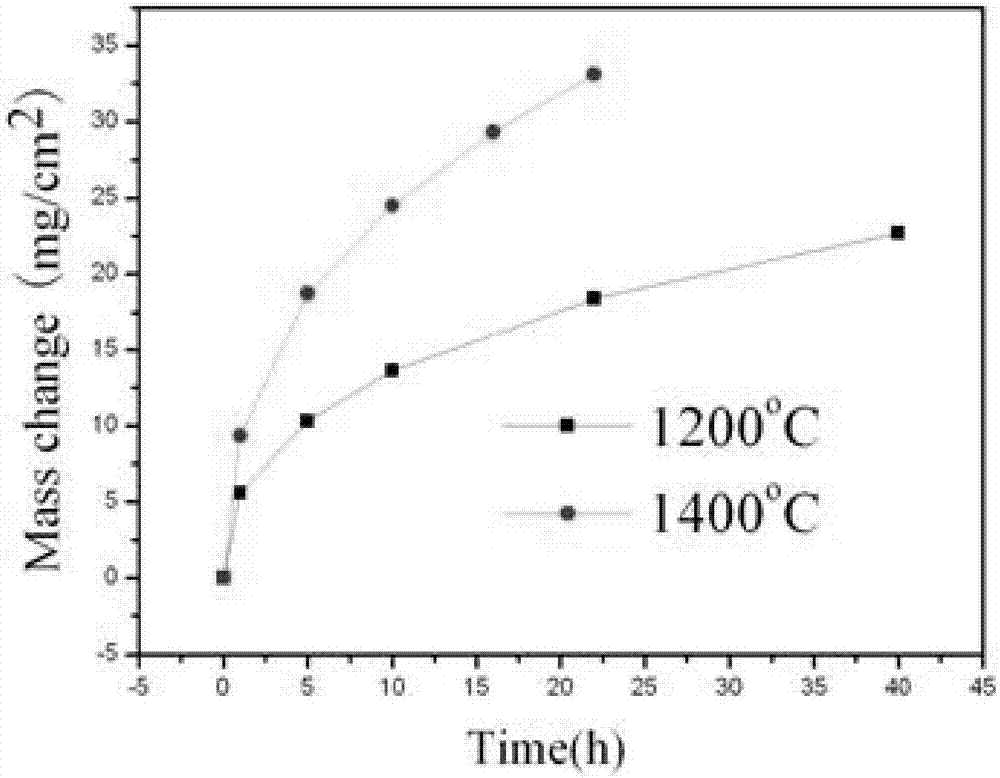

[0037] The microscopic region of the modified composite Hf-Ta metal coating prepared on the surface of the refractory metal in this example is flat, indicating that the metal coating melts well in the process of pre-sintering and laser cladding, and the modified composite Hf-Ta The metal coating is very continuous, and the metal coating is well combined with the refractory metal substrate, which is beneficial to provide better high temperature protection for the refractory metal substrate; the oxidation test shows that the modified composite prepared in this embodiment on ...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1, pickling the surface of the refractory metal after grinding, and then performing sandblasting and degreasing treatment on the surface of the refractory metal after pickling; the sand used in the sandblasting is zirconia sand, and the sandblasting The processing pressure is 0.3MPa; the refractory metal is a C103 alloy; the acid solution used in the pickling is mixed by hydrofluoric acid and concentrated nitric acid in a volume ratio of 3:2, and the mass concentration of the hydrofluoric acid is 60%, the mass concentration of the concentrated nitric acid is 65%; preferably, the refractory metal is immersed in acetone to carry out degreasing treatment;

[0041] Step 2: Put the mixed powder and dispersant in a ball mill and mix them uniformly to obtain a modified composite Hf-Ta slurry; the mixed powder is uniformly mixed with tantalum powder, hafnium powder and modified metal powder, and the mixed The mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com