Optimum design method of dynamic performance of aero-engine fastening junction surface

An aero-engine and dynamic performance technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as long design cycle, irregular shape, and impact of aero-engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and embodiment this method is described in detail;

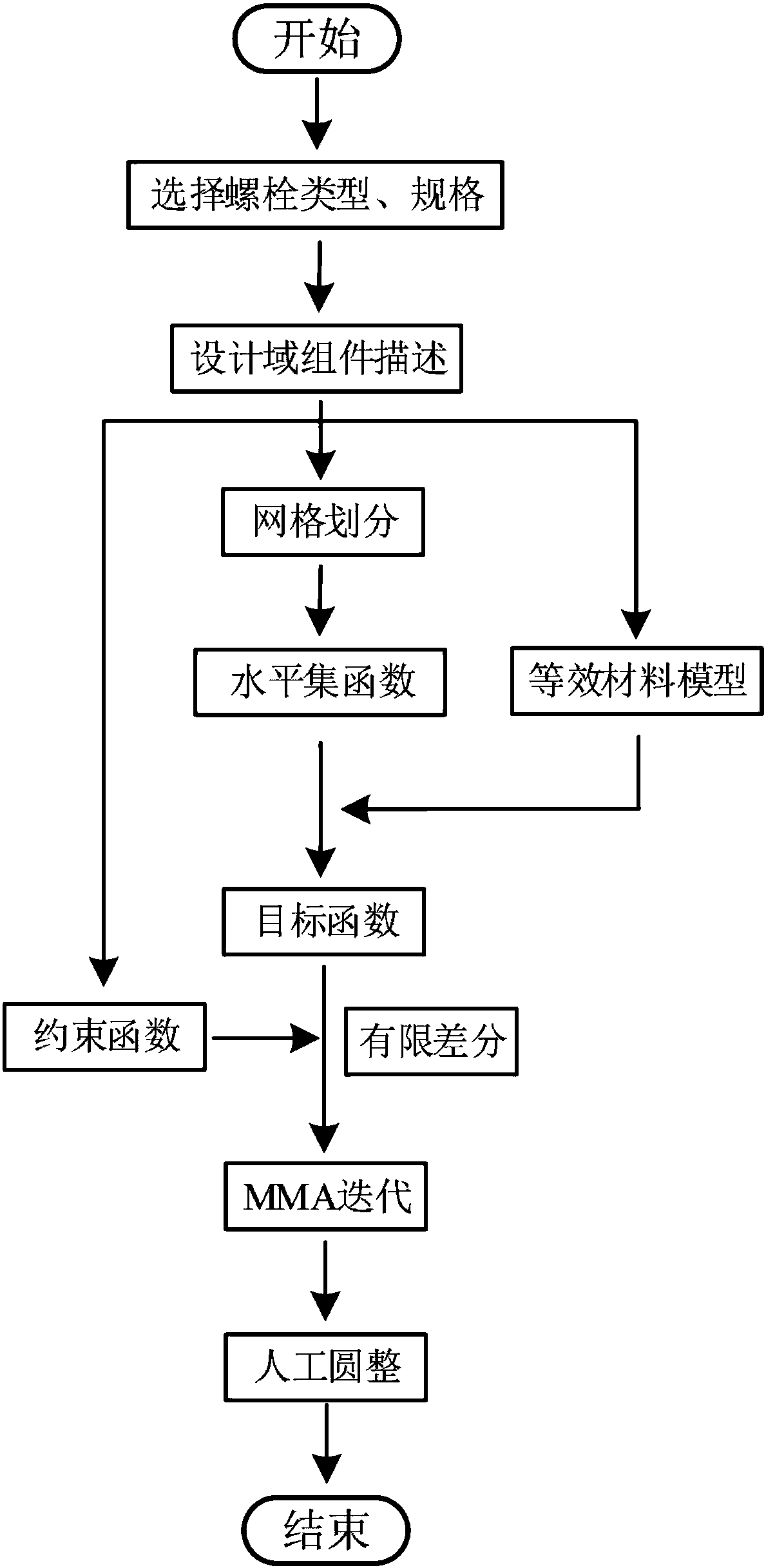

[0069] Such as figure 1 As shown, an optimal design method for the dynamic performance of the fastened joint surface of an aero-engine includes the following steps:

[0070] 1) According to the needs of the actual assembly of the aero-engine, determine the type, specification, assembly process and machining accuracy of the bolts used;

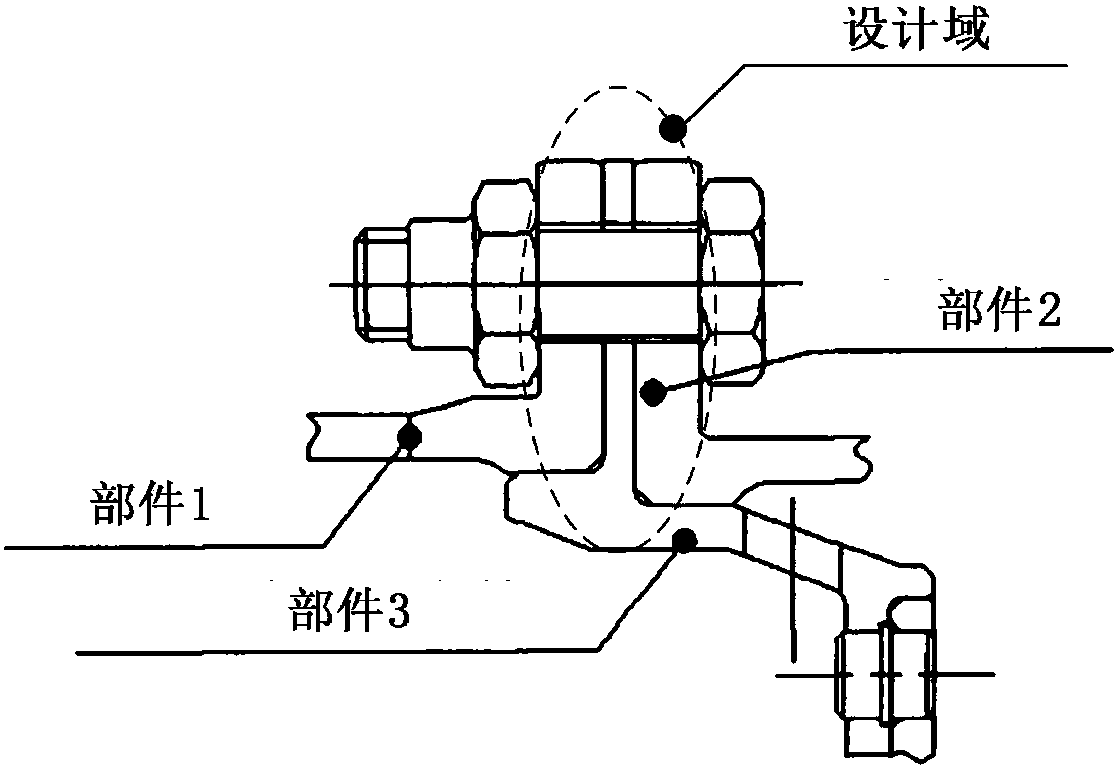

[0071] 2) if figure 2 As shown in the figure, the fastening surface of parts 1, 2 and 3 in the aero-engine is selected as the design domain D, which is described by rectangular components; five design variables are set for each rectangular component, which are: the coordinates of the center point of the rectangle x 0 、y 0 , the length L and width T of the rectangular component, the inclination angle θ of the rectangular component;

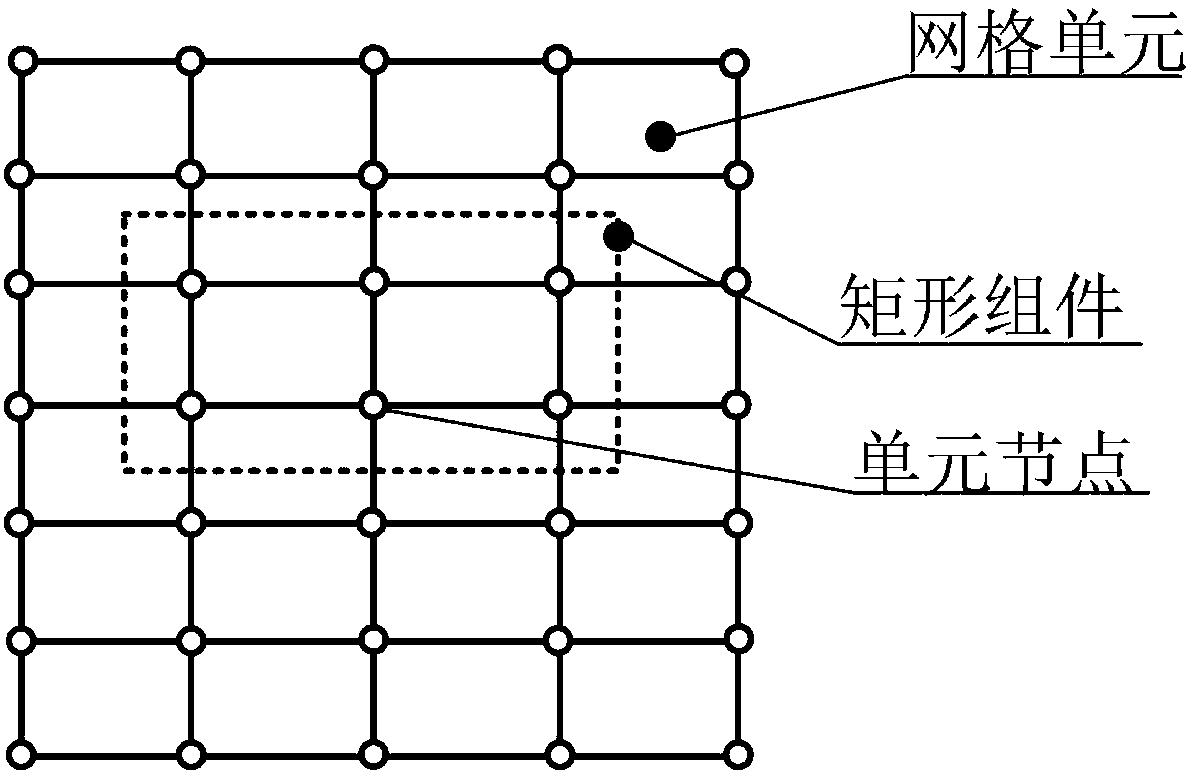

[0072] 3) By using several small four-node quadrilateral grids to divide the design domain, a total of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com