Hydraulic design method of high-lift axial flow pump impeller

A hydraulic design and axial flow pump technology, applied in the field of nuclear power, can solve the problems that it is difficult to achieve the expected effect, and the theoretical design and the actual model are different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

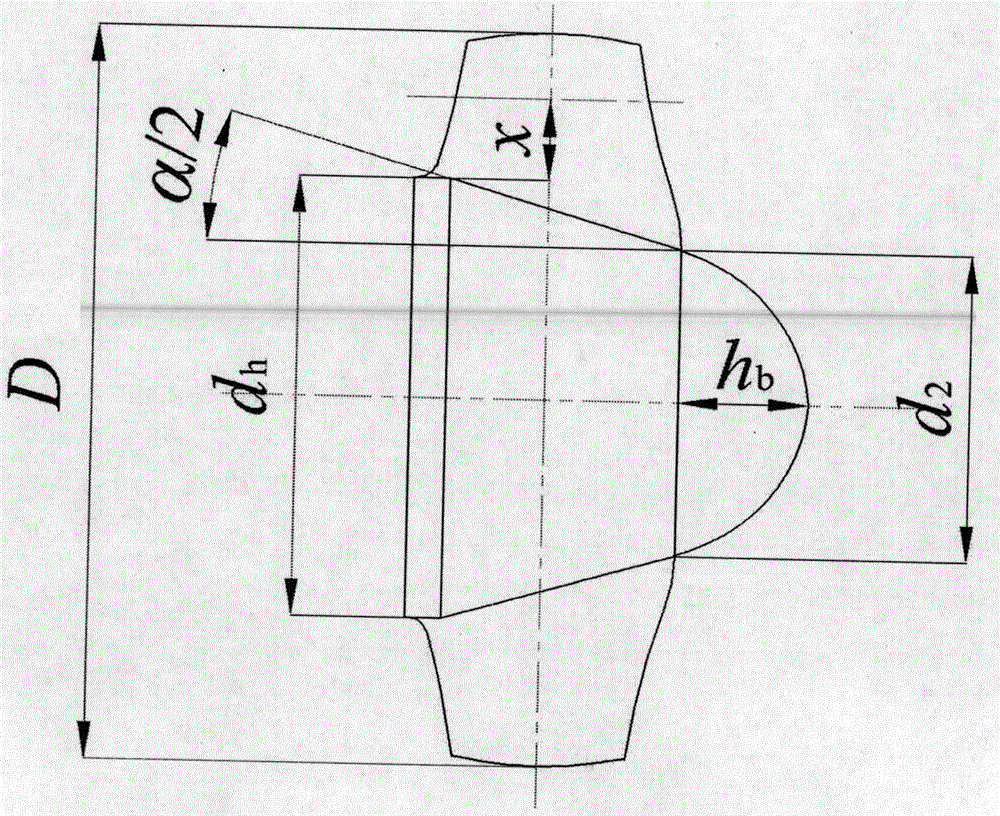

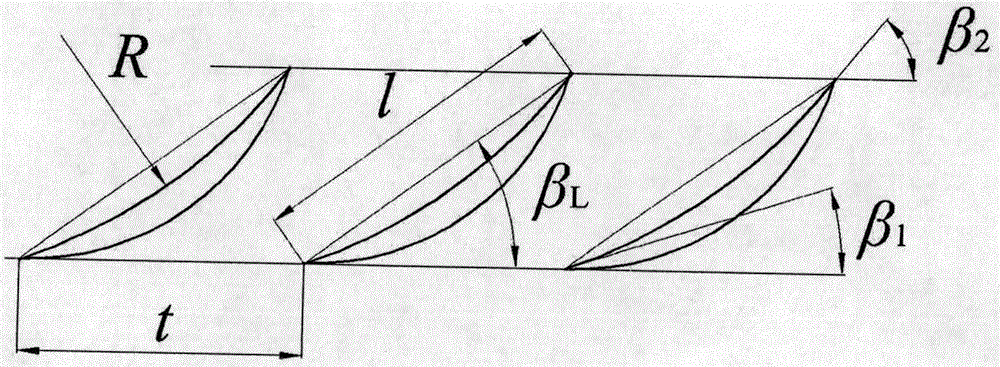

[0145] The present invention uses the following formulas to determine the impeller head coefficient ψ of the axial flow pump, the impeller hub ratio R d , Impeller diameter D, blade inlet shaft speed v m1 , The blade outlet axial velocity v m2 , The circumferential sub-velocity at the blade exit v u2 、The density of the cascade on the side of the impeller hub S h 、Dense density of cascade on side of impeller flange S 0 、The angle coefficient of blade exit K β2 、The blade inlet placement angle coefficient K β1 , Blade inlet placement angle β 1 , The blade exit placement angle β 2 , The number of impeller blades z, the maximum blade thickness δ max , Profile radius R, hub diameter at the impeller inlet d 2 , Impeller hub diffusion angle α, impeller round nut height h b Several parameters of the impeller and different cross-sectional forms of the blades.

[0146] In this embodiment, the hydraulic parameters of the impeller are calculated under the given design working condition flow Q,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com