Three-dimensional wiring design method of helicopter comprehensive testbed

A comprehensive test bench and three-dimensional wiring technology, which is applied in the field of three-dimensional wiring of the electrical system in the development process of the helicopter comprehensive test bench, can solve problems such as omissions, high rework rate, and long design cycle, and achieve low cost, change hysteresis, and synchronous design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

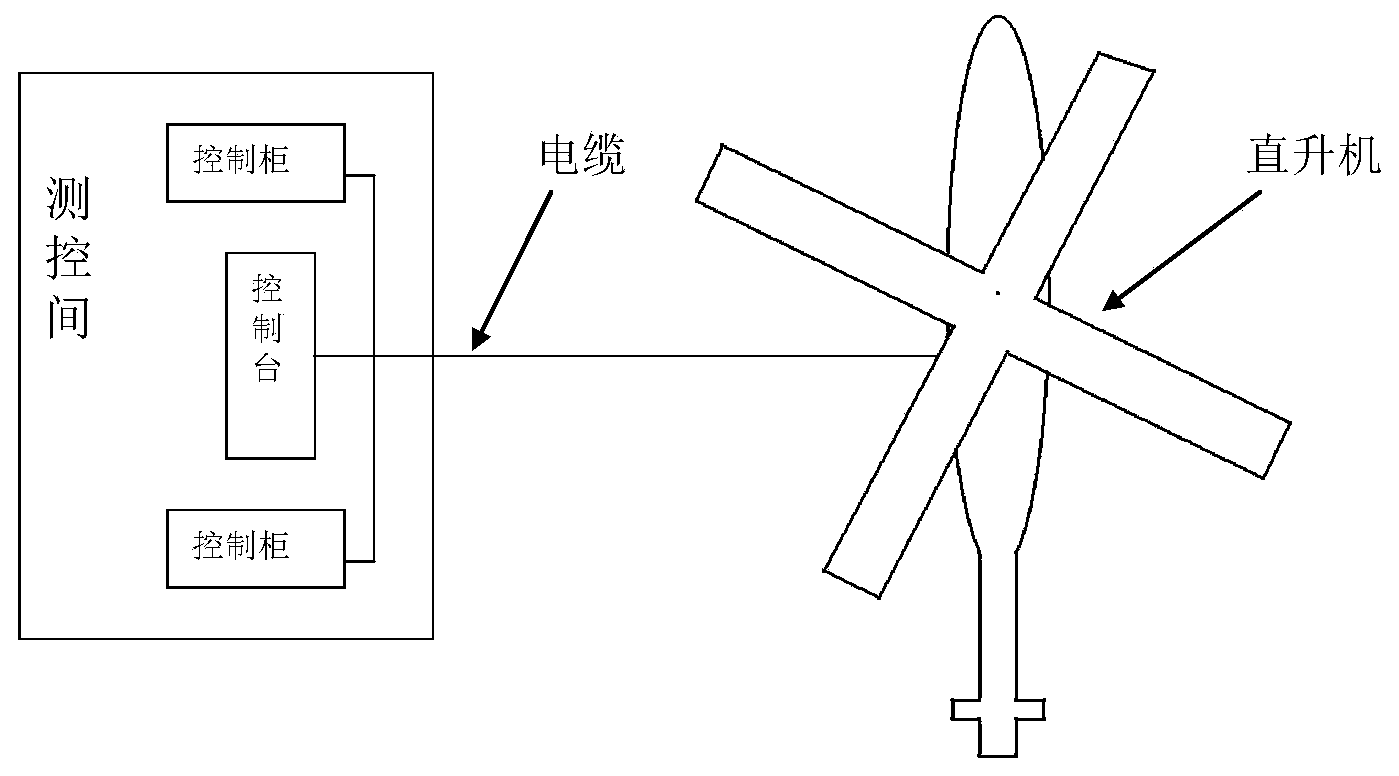

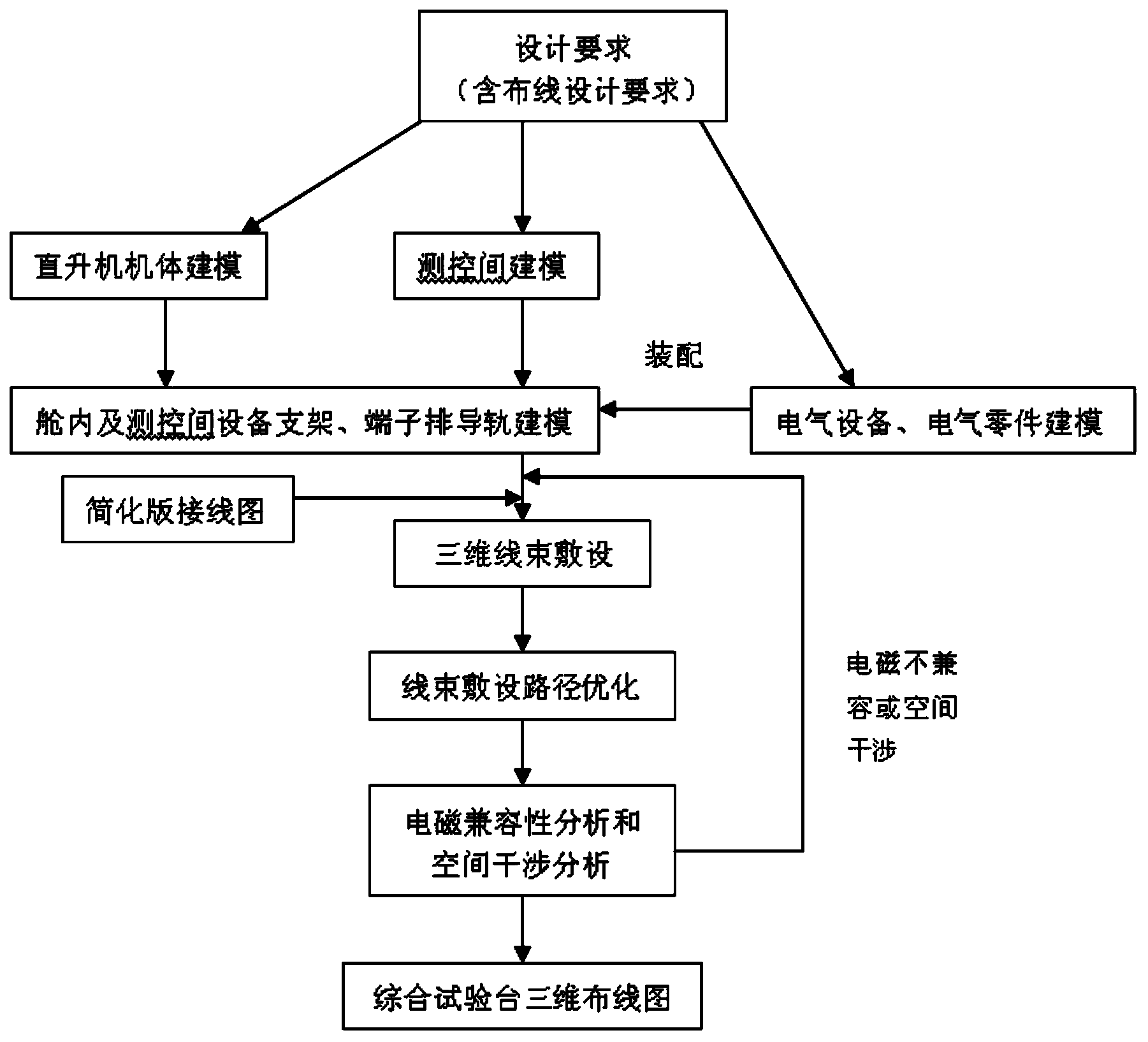

[0033] The specific modeling process of the 3D wiring of the helicopter test rig is determined based on the fact that the helicopter comprehensive test rig has many electrical devices and wiring harness branches.

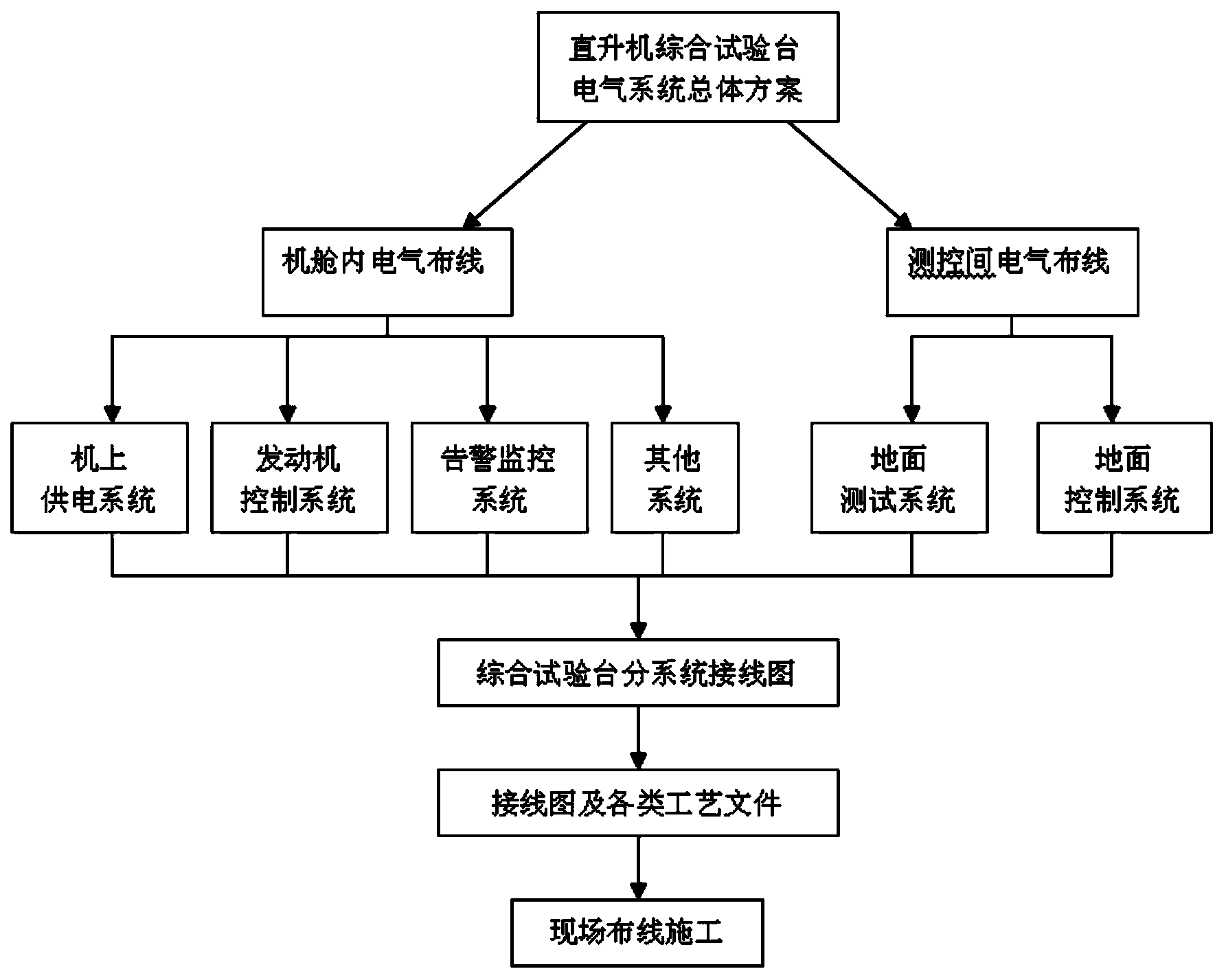

[0034] (1) Design and analysis of wiring diagram

[0035] According to the product description provided by the equipment manufacturer in the measurement and control room and the engine room and the functions to be realized by the equipment, the wiring relationship between the equipment is summarized; refer to the corresponding aviation product design specifications, select the appropriate cable type; determine the overall electrical design plan, according to the overall The scheme uses AutoCAD software to draw two-dimensional wiring diagrams. In the wiring diagrams, it is only necessary to provide the equipment code and the cable model between the equipment.

[0036] (2) Mechanical structure modeling

[0037] The mechanical structure in the embodiment refers to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com