Double-stator variable frequency speed regulation asynchronous motor

An asynchronous motor and variable frequency speed regulation technology, applied in electrical components, electromechanical devices, etc., can solve the problems of cramped test bench space, high equipment manufacturing cost, and cumbersome test preparation process, to meet the requirements of the operating environment and improve the load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

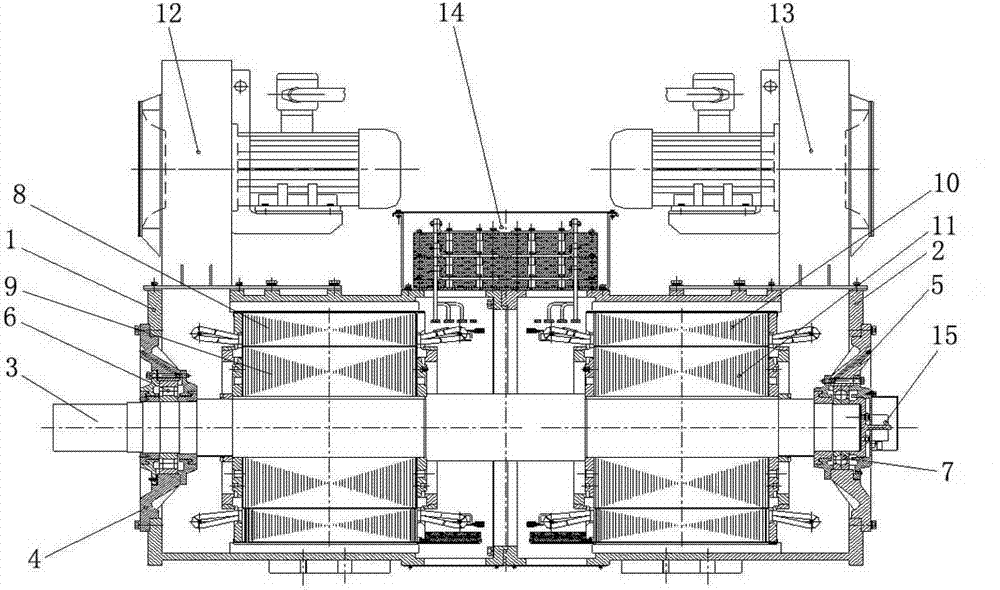

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, a double-stator variable frequency speed regulation asynchronous motor includes a left frame 1, a right frame 2 and a rotating shaft 3, and the right port of the left frame 1 and the left port of the right frame 2 pass through a stopper, a positioning pin and a bolt Docking and fixing, the left end cover 4 is installed on the left port of the left machine base 1, and the right end cover 5 is installed on the right port of the right machine base 2; the rotating shaft 3 runs through the axes of the left machine base 1 and the right machine base 2, The left end of 3 is the transmission end and is installed on the left end cover 4 through the transmission bearing 6, and the left inner and outer steel cardboard, the left inner and outer bearing caps and the left inner sealing ring are also installed on the left end cover 4; the right end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com