Kinematics and total working condition elastic tester of suspension bracket

A technique of elasticity test and kinematics, applied in wheel test, vehicle test, car tire test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

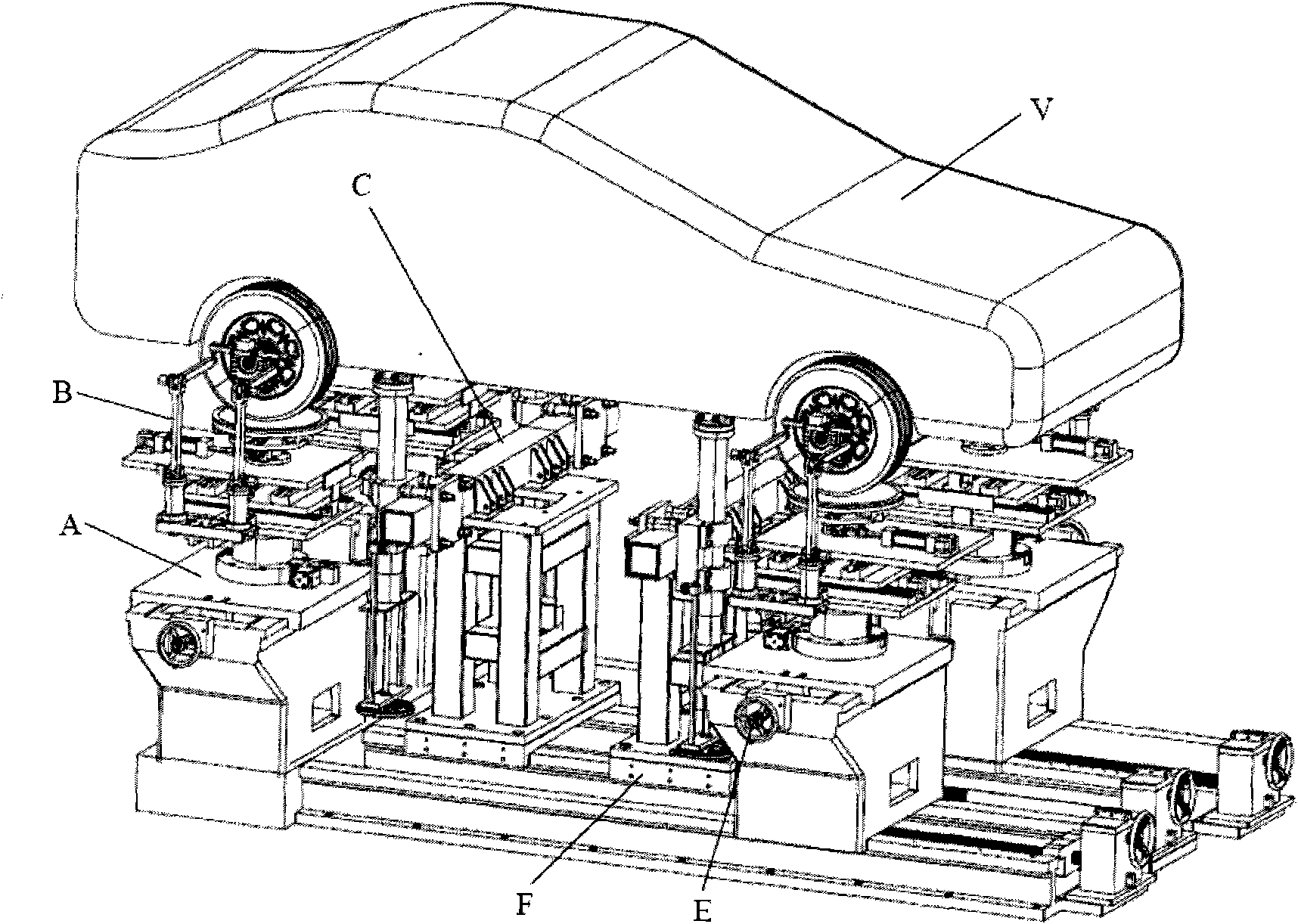

[0016] Such as figure 1 Shown is the basic structure of the vehicle K&C testing machine.

[0017] It is composed of a loading table A, a six-degree-of-freedom measuring mechanism B, a body clamping system C, a wheelbase adjustment system E (the biaxial testing machine also has a wheelbase adjustment system F), and a data acquisition and processing system. The wheel of the tested suspension of the tested vehicle V is supported on the loading table A, the skirt of the body is clamped by the body holding system C, the loading table A applies force to the wheel, and the deformation of the wheel is measured by the six-degree-of-freedom measuring mechanism B .

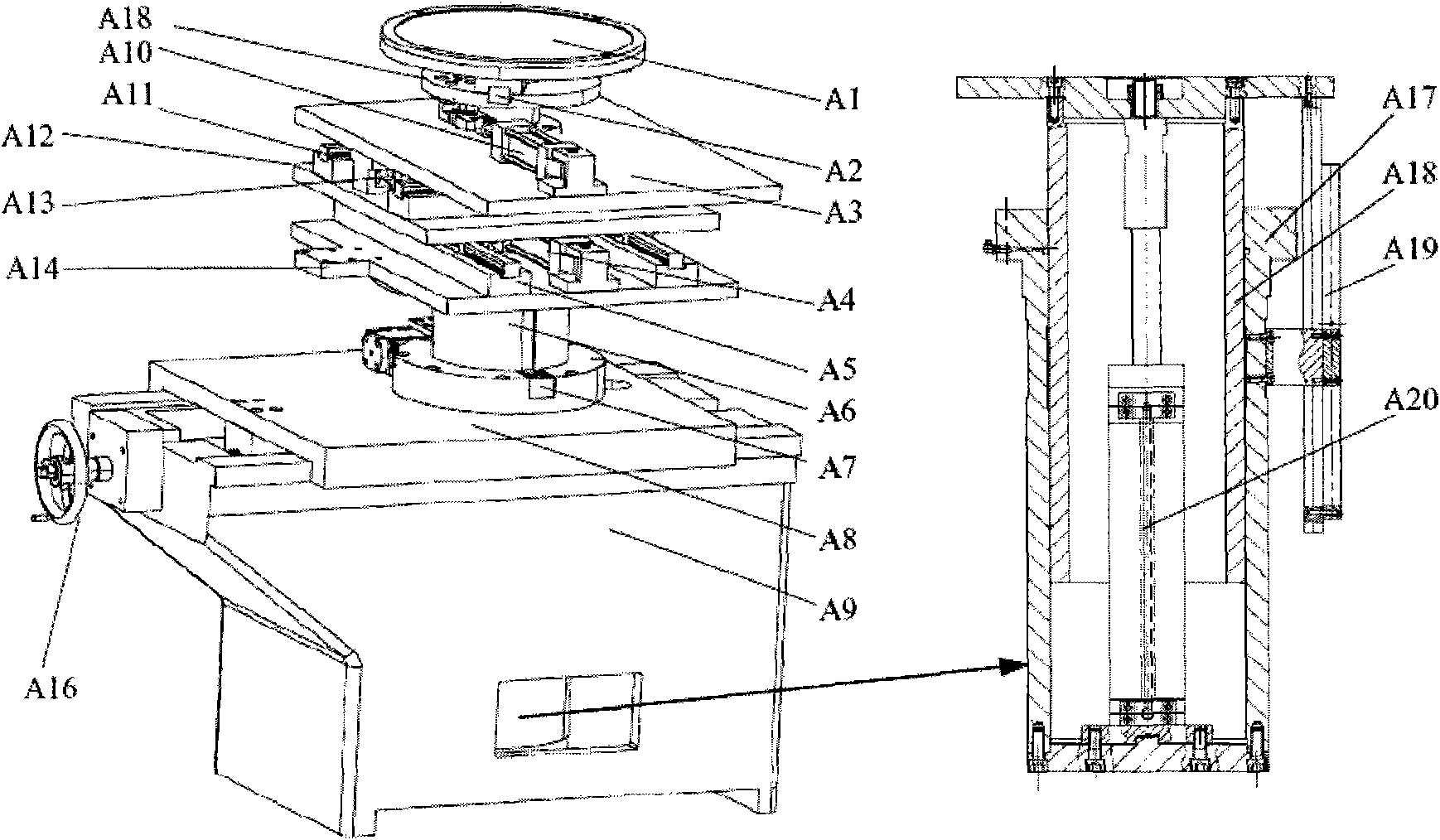

[0018] Such as figure 2 Shown is the loading table structure of the K&C testing machine.

[0019] The loading platform is composed of three layers of platforms, vertical cylinder A19 and motion platform A14 to form an afterburner assembly that slides along the axial direction of the sleeve A17 with the guide column A6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com