Detection process for run-out amount of steel ring rim and equipment structure

A testing process and testing equipment technology, applied in wheel testing, angle/taper measurement, mechanical counter/curvature measurement, etc., can solve the problems of different, inaccurate steel ring rim runout data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

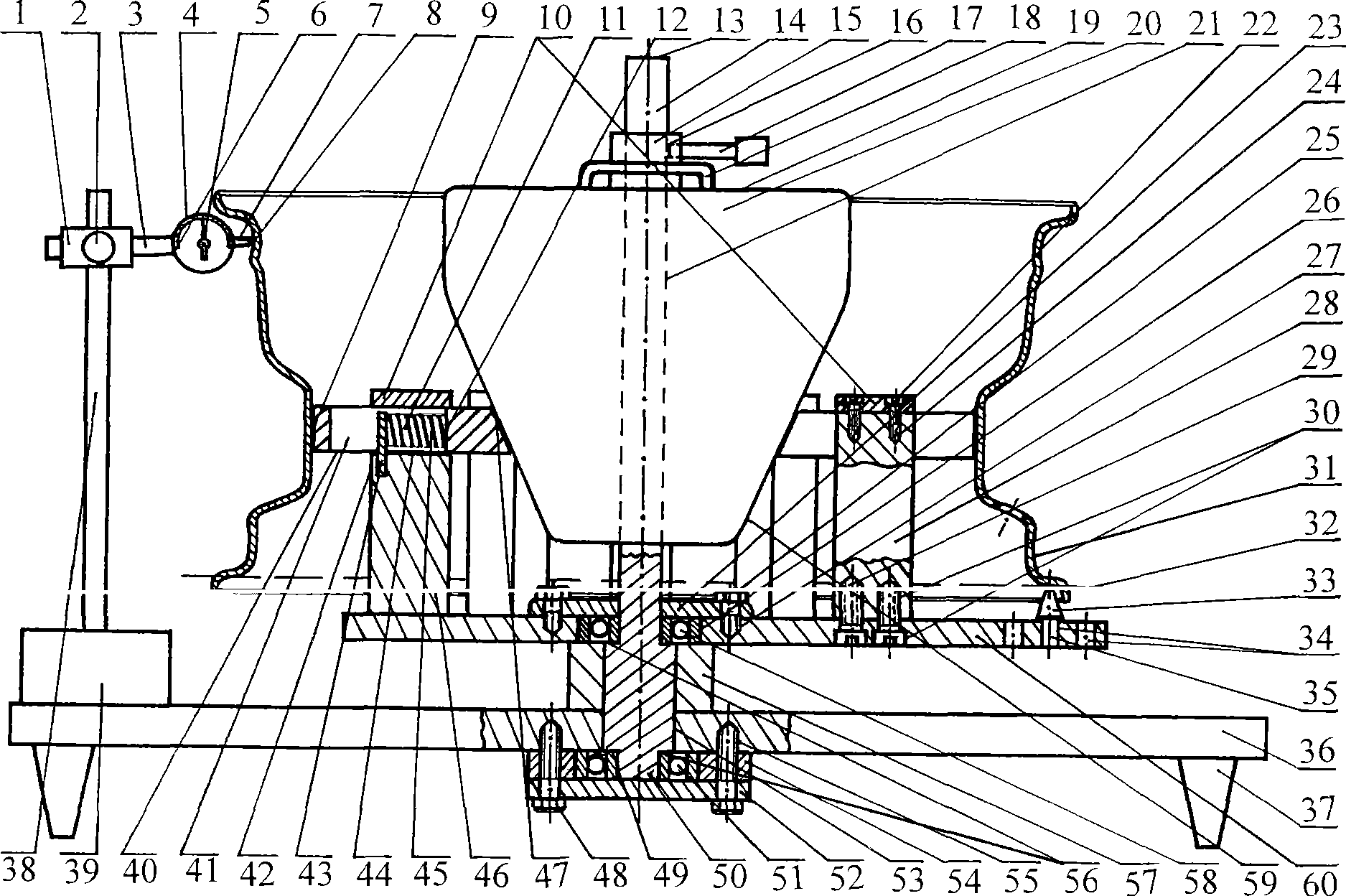

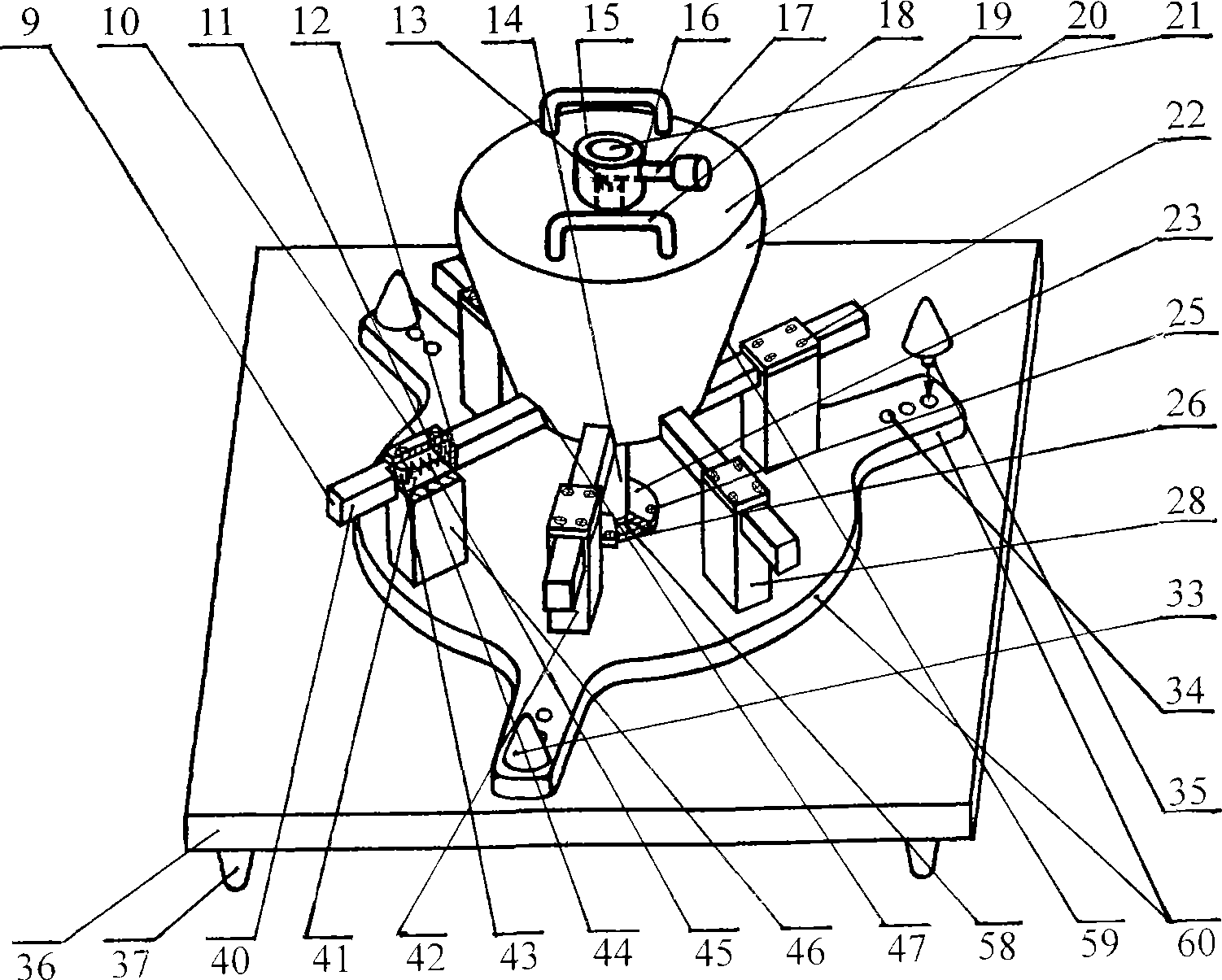

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Steel ring rim runout detection process and equipment structure, such as figure 1 and figure 2 As shown, it includes the detection process of the steel ring rim runout and the structure of the steel ring rim runout detection equipment: Among them, the structure of the steel ring rim runout detection equipment, firstly, the composition of the body is set as a steel ring rim runout detection fixture and the instrument frame assembly, and further divide the steel ring rim runout detection fixture into a mandrel assembly, a rotating disk assembly, multiple sets of telescopic devices, a pressing block assembly, and a bench assembly. Connect the bench assembly with the rotating disk assembly, connect the briquetting block assembly with the mandrel assembly and the rotating disk assembly, and integrate the steel ring rim runout detection fixture, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com