Method with combination of low-temperature superfine grinding and ultrasonic subcritical extracting for almond oil

A low-temperature ultra-fine pulverization and critical extraction technology, which is applied in the production of fat/fat and fat production, can solve the problems of inability to ensure sufficient extraction of almond oil by rolling, restricting the continuous production of almond oil, and residual harmful solvents, etc. Large-scale industrialized continuous production, wide production practicability, no solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

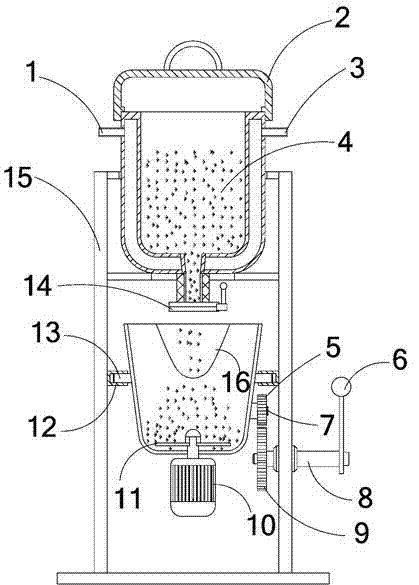

[0038] Example 1: Extraction of almond oil by combining low-temperature ultrafine pulverization and ultrasonic subcritical extraction

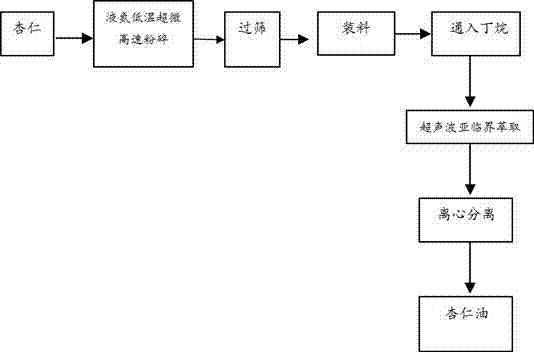

[0039] See attached figure 1 , a method of combining almond oil with low-temperature ultrafine pulverization and ultrasonic subcritical extraction. The specific method is realized through the following technical steps:

[0040] (1) After the almonds are peeled and dried at room temperature, the moisture content should be controlled between 1% and 3%. The specially designed low-temperature and high-speed crushing device is used for crushing, so that the processed almond raw materials are directly processed at high speed by liquid nitrogen low temperature treatment. Ultrafine grinding, under the conditions of temperature -100°C, low-temperature treatment of materials for 10s, and rotating speed of 3000 rpm, to avoid sticky almonds due to heat during the high-speed ultrafine grinding process due to the very high content of almond oil, making it...

Embodiment 2

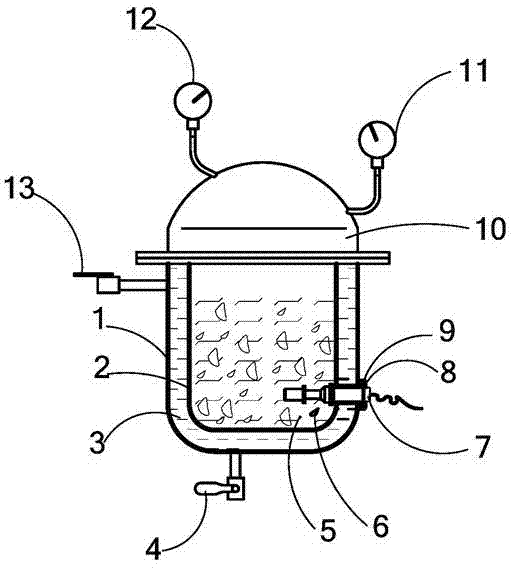

[0055] Example 2: Extraction of Almond Oil by Combining Low-Temperature Ultrafine Pulverization and Ultrasonic Subcritical Extraction

[0056] (1) Weigh the peeled and dried almonds and use a liquid nitrogen ultrafine pulverizer to crush them at low temperature and pass them through a 60-mesh sieve.

[0057] (2) Put the almonds crushed and sieved at low temperature into a 200-mesh sieve, spread them flat and roll them into the extraction axe, after vacuuming, put butane into the extraction tank, the solid-to-liquid ratio (almond powder: butane) 1:6.5, turn on the heater and hot water pump, raise the temperature to 50°C, keep the pressure at 0.6Mpa, then turn on the ultrasonic device at the bottom of the ultrasonic-subcritical combined extraction device, under the conditions of ultrasonic power 450 W and ultrasonic frequency 40KHZ Fully react for 30 minutes, then carry out precipitation, turn on the compressor, pump to 0.1Mpa, then turn on the vacuum pump to pump 4 times to -...

Embodiment 3

[0059] Example 3: Extraction of Almond Oil by Combining Low-Temperature Ultrafine Pulverization and Ultrasonic Subcritical Extraction

[0060] (1) Weigh the peeled and dried almonds and use a liquid nitrogen ultrafine pulverizer to pulverize them at low temperature and pass through a 40-mesh sieve.

[0061] (2) Put the almonds crushed and sieved at low temperature into a 200-mesh sieve, spread them flat and roll them into the extraction axe, after vacuuming, put butane into the extraction tank, the solid-to-liquid ratio (almond powder: butane) 1:8.5, turn on the heater and hot water pump, raise the temperature to 40°C, keep the pressure at 0.5Mpa, then turn on the ultrasonic device at the bottom of the ultrasonic-subcritical combined extraction device, under the conditions of ultrasonic power 400 W and ultrasonic frequency 40KHZ After fully reacting for 50 minutes, carry out precipitation, turn on the compressor, pump to 0.1Mpa, then turn on the vacuum pump to pump 4 times t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com