Low-carbon olefin catalyst prepared from low-carbon alkane through dehydrogenation and preparation method thereof

A technology for low-carbon alkanes and low-carbon olefins, applied in the field of catalysts and their preparation, can solve the problems of poor catalyst stability, easy crushing, insufficient mechanical strength of catalysts, etc., and achieve the effects of stable performance and good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 90g of pseudo-boehmite raw powder with an average particle size of 26μm or other inorganic oxygen-containing compounds of aluminum to 220.2g of the main raw material of pseudo-boehmite with an average particle size of 40μm, then add 9g of kale powder and then add 130ml After fully kneading with deionized water, extrude, place at room temperature for 12 hours, then hold at 90°C for 3 hours, and then dry at 120°C for 10 hours, and process at 750°C to obtain the carrier.

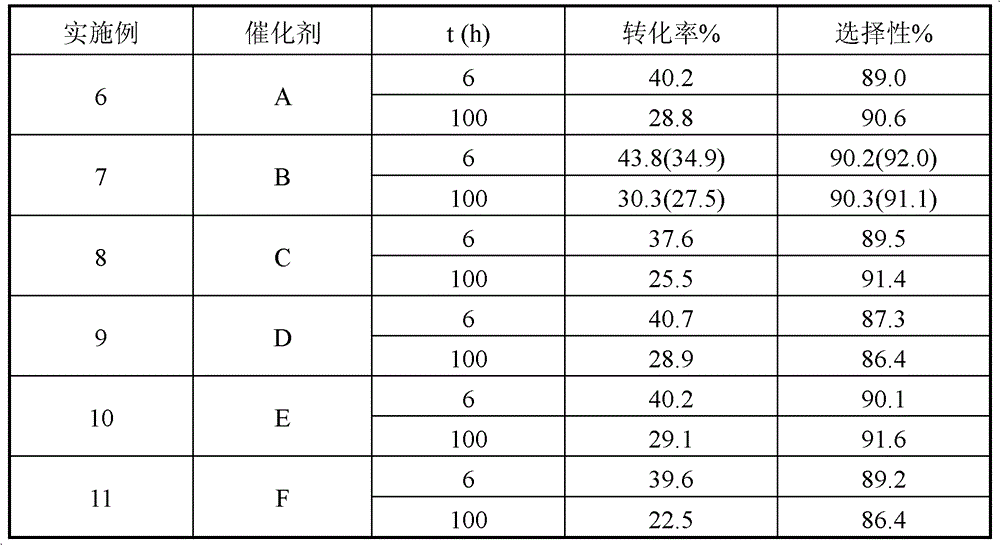

[0033] The composite alumina carrier obtained adopts the impregnation technology to load the active component, that is, the chloroplatinic acid (H 2 PtCl 6 6H 2 O, 2.23g), SnCl 4 ·5H 2 O, 7.4g; NaNO 3, 3.5g of mixed aqueous solution for 24 hours (metal platinum loading 0.4%), then dried at 60°C, calcined at 530°C in air flow for 3 hours, then treated with water vapor at 530°C for 4 hours, and finally passed dry air at 530°C Treat for 1 hour to obtain a catalyst sample, denoted as A. See Table ...

Embodiment 2

[0036] Add 98g of alumina component B pseudo-boehmite raw powder with a particle size of 16μm in 236g of pseudo-boehmite raw powder alumina component A main material with an average particle size of 32μm, and then add 12g of safflower powder and then add 140ml of deionized water was fully kneaded and extruded, left at room temperature for 12 hours, then kept at 90°C for 3 hours, then dried at 120°C for 10 hours, and treated at 750°C to obtain a carrier.

[0037] Catalyst is prepared according to the method of embodiment 1, the difference is that SnCl 4 ·5H 2 O, 11.0g; NaNO 3 , 7.4g; H 2 PtCl 6 6H 2 O, 4.6g, recorded as B. See Table 1 for the composition (%) and strength of the catalyst in terms of weight percent by element.

Embodiment 3

[0039] In 220g of alumina component A pseudo-boehmite raw powder main material whose average particle size is 40 μm, add 94 g of alumina component B pseudo-boehmite raw powder with an average particle size of 26 μm, then add 9 g of safflower powder and then add Add 130ml of deionized water, knead well, extrude, place at room temperature for 12 hours, then keep at 90°C for 3 hours, then dry at 120°C for 10 hours, and process at 750°C to obtain the carrier.

[0040] Prepare catalyst by the method for embodiment 1, SnCl 4 ·5H 2 O, 1.7g; NaNO 3 , 0.6g; H 2 PtCl 6 6H 2 O, 1.1g, denoted as C. See Table 1 for the composition (%) and strength of the catalyst in terms of weight percent by element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com