Phase change temperature-adjusting asphalt compound material for traffic pavement and preparation method thereof

A technology of composite materials and composite phase-change materials, which is applied in the field of phase-change temperature-adjusting asphalt composite materials for traffic pavements and its preparation, can solve the problems of poor high-temperature stability of phase-change pavement materials, and achieve improved cohesion and improved Adhesion ability, effect of improving ceramic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

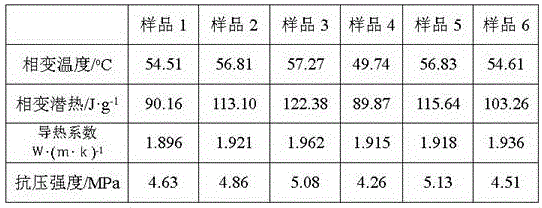

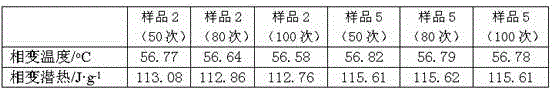

Embodiment 1

[0029] A phase-change temperature-regulating asphalt composite material for traffic pavement, wherein it is characterized in that: it is made of aggregate, base asphalt, composite phase-change material, asphalt modified material, stabilizer and antioxidant, wherein the aggregate accounts for 70 parts, 7 parts of basic asphalt, 8 parts of composite phase change material, 5 parts of asphalt modified material, 0.5 part of stabilizer, and 0.5 part of antioxidant; the aggregate is composed of coarse The asphalt modified material is composed of polyethylene or polypropylene waste, waste tire powder and medium powder with a weight ratio of 15:3:2. The medium powder is made of slurry waste diatom mud after drying After drying and pulverizing, mix it with the sodium hydroxide solid of 2 times the weight of the waste diatomaceous earth in slurry form and mix it at 40 o It is made by heating under C; the composite phase-change material is composed of metal powder and ceramic-based phase-...

Embodiment 2

[0039] A phase-change temperature-regulating asphalt composite material for traffic pavement, which is made of aggregate, base asphalt, composite phase-change material, asphalt modified material, stabilizer and antioxidant. According to the weight ratio, the aggregate accounts for 75 parts, and the base asphalt 10 parts, composite phase change material 15 parts, asphalt modified material 8 parts, stabilizer 1 part, antioxidant 1 part; the aggregate is composed of coarse material and fine material with a weight ratio of 2.5:1 , the asphalt modified material is composed of polyethylene or polypropylene waste, waste tire powder and medium powder with a weight ratio of 15:5:2. The medium powder is dried and pulverized with pulpy waste diatom mud Slurry waste diatomaceous earth 2 times the weight of sodium hydroxide solid mixed and mixed at 45 o It is made by heating under C; the composite phase change material is composed of metal powder and ceramic base phase change material with...

Embodiment 3

[0050]A phase-change temperature-regulating asphalt composite material for traffic pavement, which is made of aggregate, base asphalt, composite phase-change material, asphalt modified material, stabilizer and antioxidant, wherein the aggregate accounts for 73 parts by weight, and the base Asphalt accounts for 8.5 parts, composite phase change material accounts for 11 parts, asphalt modified material accounts for 7 parts, stabilizer accounts for 0.75 parts, and antioxidant accounts for 0.75 parts; the aggregate is composed of coarse material and fine material with a weight ratio of 2.3:1 Composition, the asphalt modified material is composed of polyethylene or polypropylene waste, waste tire powder and medium powder with a weight ratio of 15:4:2. The medium powder is dried and crushed slurry-like waste diatom mud Mix the sodium hydroxide solid with 2 times the weight of the slurry waste diatomaceous earth and mix it at 50 o It is made by heating under C; the composite phase ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com