Double-fluid single-system air pressure energy storage grouting machine and grouting process

A single-system, grouting machine technology, which is applied in the field of water leakage treatment of structures and underground buildings, can solve problems such as unreasonable setting of grouting channels, reduction of mechanical properties of gel, uneven mixing of grout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

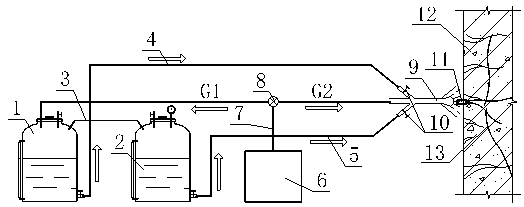

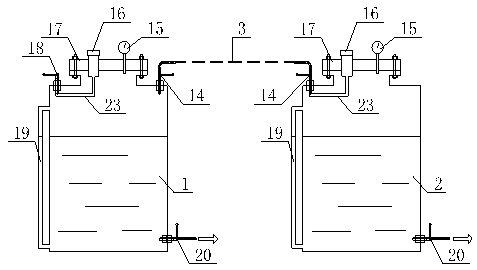

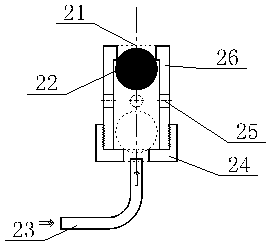

[0055] The specific implementation manners of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The described embodiments are part, but not all, of the invention. The methods, means and steps described in the implementation cases of the present invention all belong to the protection scope of the present invention (provided that those skilled in the industry do not make creative work).

[0056] The implementation case is the water leakage control project of the settlement joints in the basement of a building. The building is a two-story underground structure, with a total of 6 settlement joints. The second-floor seepage water soaks to a depth of 20cm, which is mainly caused by leaking water from leaking water cracks 13 on the structural layer 12 (the reason for the leaking water is not mentioned here. to describe).

[0057] Step 1: Drain the accumulated water in the basement, build cofferdams on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com