Cereal grain extruding and crushing device

A technology for crushing and crushing grains, applied in grain processing, non-rotational vibration suppression, etc., can solve the problems of unsatisfactory grain crushing effect, complex structure, poor buffering and shock absorption effect, etc. , The effect of good buffering and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments:

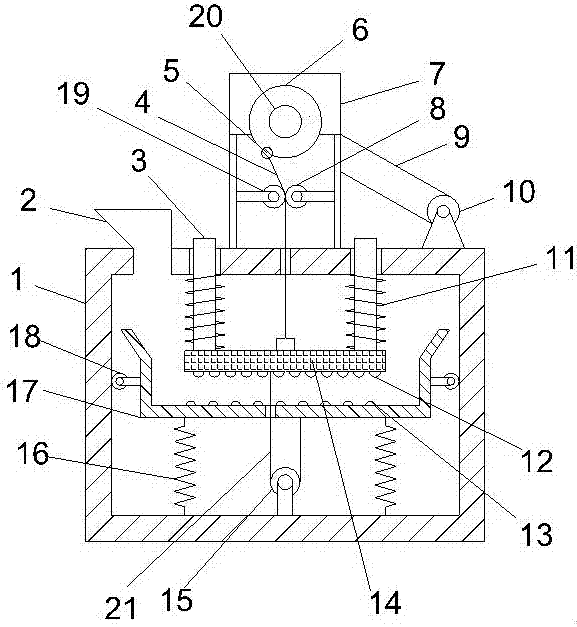

[0017] see figure 1 , a grain grain crushing device, comprising a body 1, characterized in that, the body 1 is provided with a loading frame 17, and guide pulleys 18 are fixedly installed on the left outer wall and the right outer wall of the loading frame 17 , the guide pulleys 18 are all in contact with the inner side wall of the main body 1, and several lower pressing blocks 13 are uniformly arranged on the inner bottom of the loading frame 17, and two return springs B16 are arranged inside the main body 1, and each return spring B16 One end of the back spring B16 is fixedly installed on the outer bottom of the loading frame 17, and one end of the return spring B16 is fixed on the inner bottom of the body 1; the inner bottom of the body 1 is provided with a reversing pulley 15; There is an upper pressing block 12, and two sliding columns 3 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com