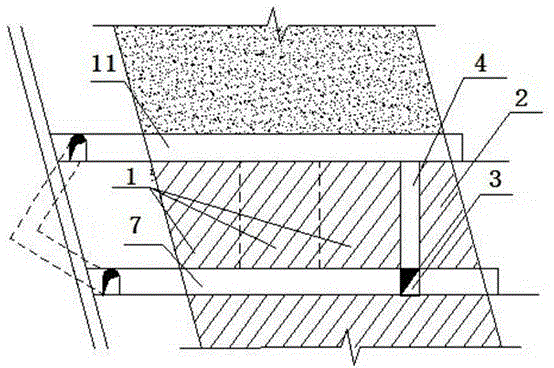

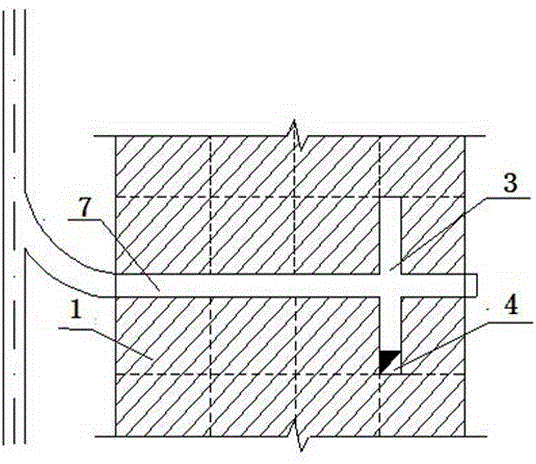

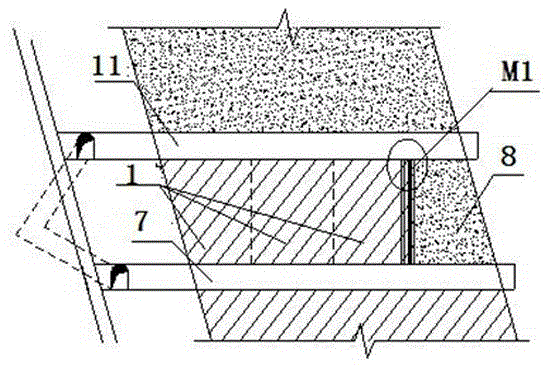

Kerve-free sublevel filling mining method

A filling mining method and slotting technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as the collapse of the stope roof and surrounding rock of the hanging wall, etc., so as to reduce the stope mining cycle and save Working time, effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Test location: in the 684m section of the 650-700m middle section of a copper mine. The surrounding rocks of the hanging wall are mainly tuff, and the lithology is relatively poor. The surrounding rocks of the footwall are mainly basalt, and tuff is partially reproduced. Folds and fractures are developed in the area, and the ore bodies are controlled by geological structures, and joints and fissures are extremely developed, resulting in extremely broken ore rocks. In the early stage of the mine, the mining method was adopted in the segmented rock drilling stage and then filled. The mining sequence of the mines was from the hanging wall to the footwall. With the increase of time, large-scale collapses of the hanging wall and roof of the mine house often occur, especially the collapse of the surrounding rocks of the upper wall. Sometimes even the surrounding rocks of the hanging wall are not completely exposed, and the stope collapses. It fills the entire goaf, making it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com